Magnetic current changeing dumper of integrated related speed sensing function and method of adaptive damping

A magneto-rheological damper and relative speed technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of affecting the overall reliability and stability of the vibration control system, increasing the cost of the vibration control system and Structural complexity, shortening the service life of the system, etc., to achieve the effect of improving adaptive performance, improving adaptability, and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

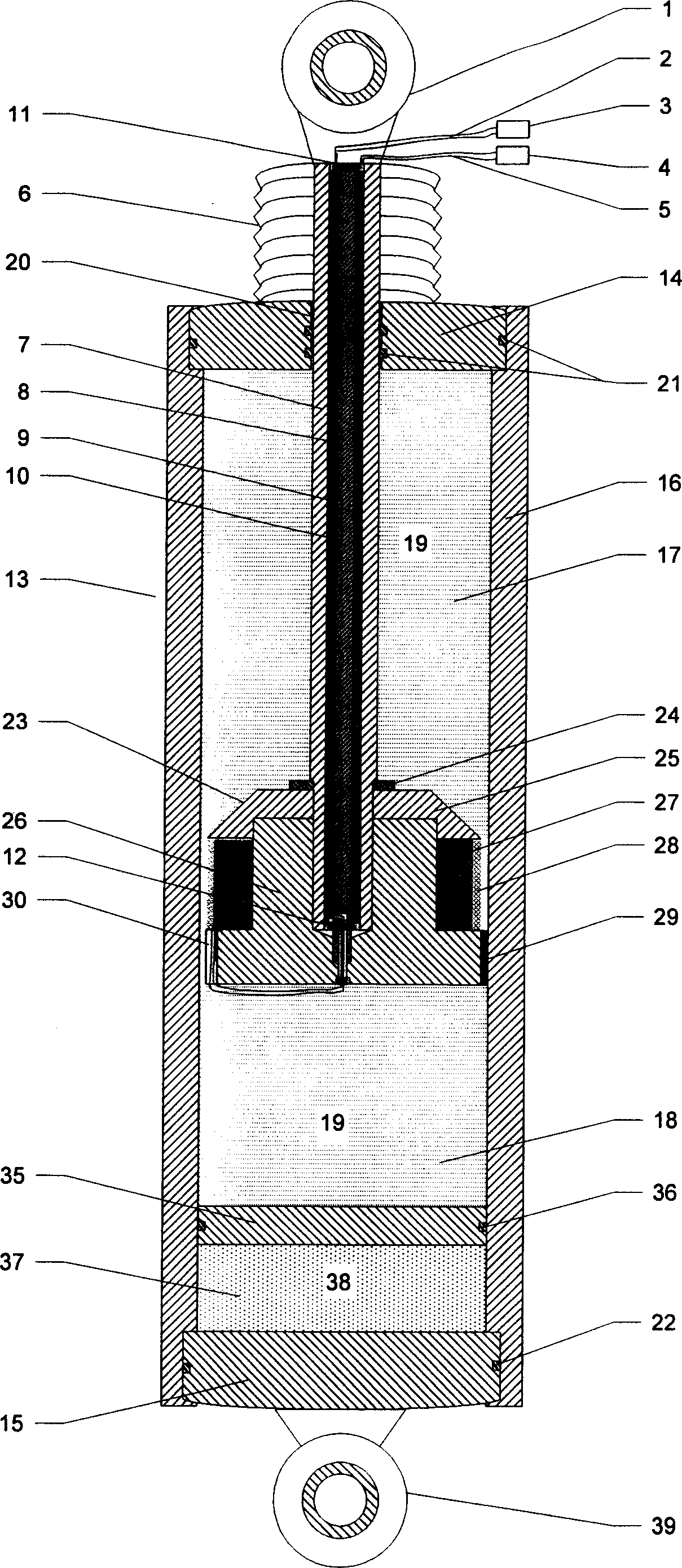

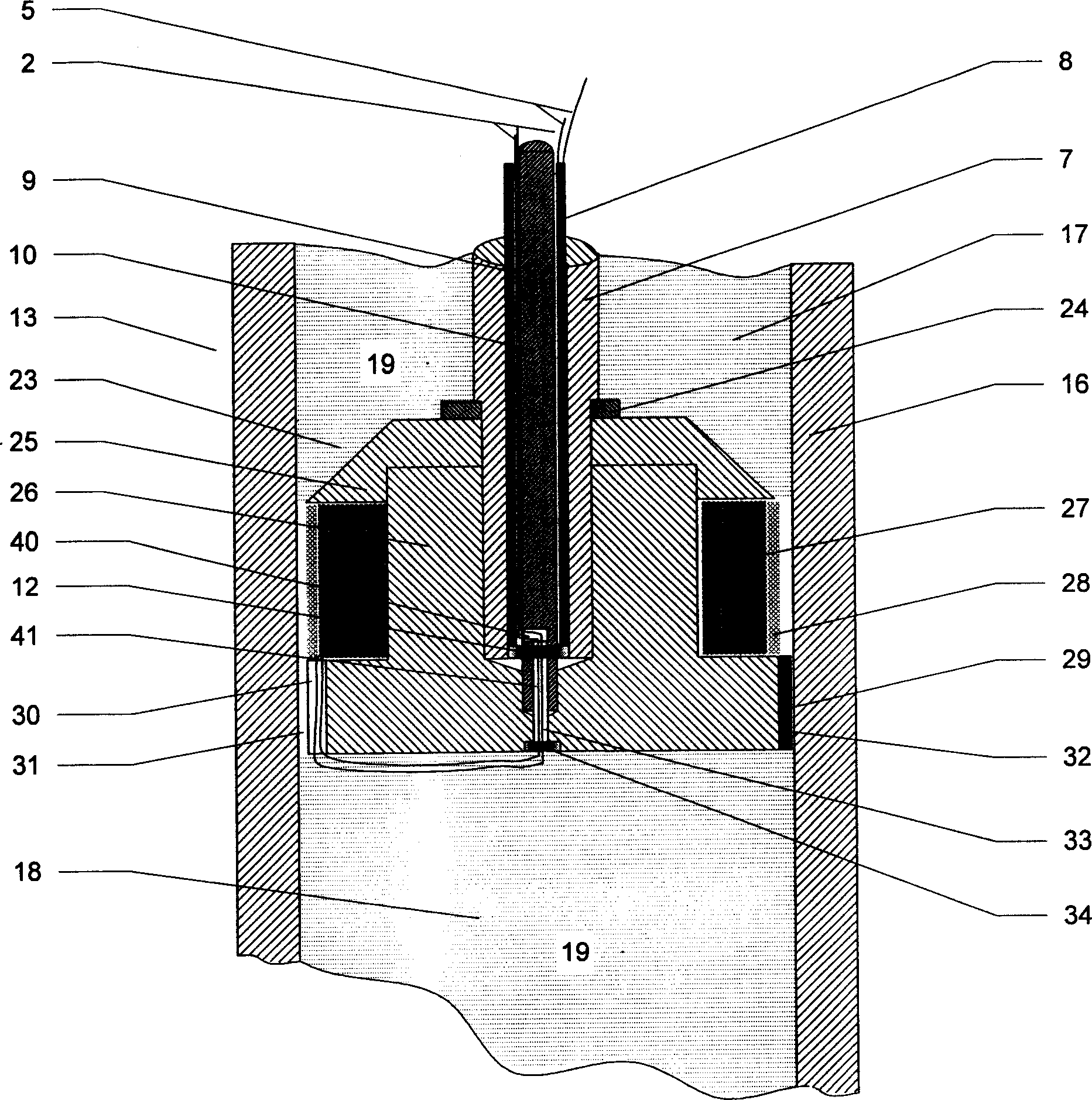

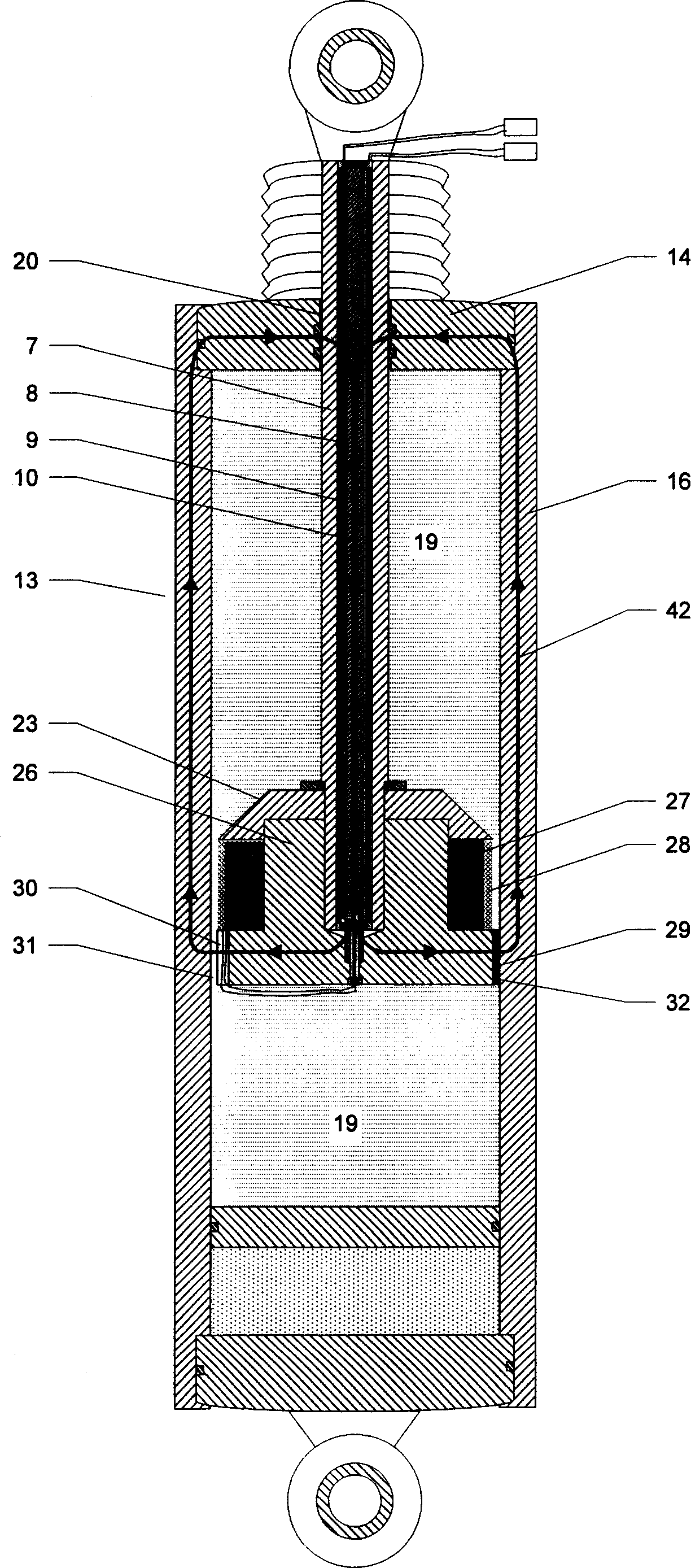

[0032] The specific structure of the present invention and the parallel working process of realizing vibration sensing and damping are described below in conjunction with the embodiments and drawings.

[0033] refer to figure 1 , figure 2 , an MR damper with integrated relative speed sensing function mainly includes a cylinder body 13, a magnetorheological fluid 19 installed in the cylinder body, a dust cover 6, a piston rod 7, a piston head 23, a sliding piston 35, a storage tank Parts such as the induction coil 8 in the energy device 37, the excitation coil 27 on the piston head, and the piston rod.

[0034] The cylinder block 13 of the damper is mainly composed of a cylinder barrel 16 with high magnetic permeability, an upper end cover 14 (through one end of the piston rod) and a lower end cover 15 with extremely low magnetic permeability.

[0035] The piston rod 7 of the damper is formed by processing low magnetic permeability material. The two ends of the piston rod ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com