New technology of synthesizing fenoxycarb

A technology of fenoxycarb and a new process, which is applied in the field of synthesizing fenoxycarb, can solve the problems of catalytic activity and selectivity decline, limit the popularization and use of fenoxycarb, and high reaction temperature, and achieve long reaction time, shortened reaction time, The effect of mild reaction conditions

Inactive Publication Date: 2005-03-23

PILARQUIM SHANGHAI +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the catalysts used in the production process of fenoxycarb mainly include active copper powder, Cu 2 O, CuCl, CuBr, etc., the active copper powder is easily oxidized, when the catalyst and the reaction mixture are exposed to the air (especially at high temperature), its catalytic activity and selectivity will drop rapidly, and the copper salt will not dissolve in the reaction system. What happens is a liquid-solid complex phase catalytic reaction, the reaction time is long, the reaction temperature is high, and the yield is low

Therefore, the high production cost limits the popularization and use of fenoxycarb

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

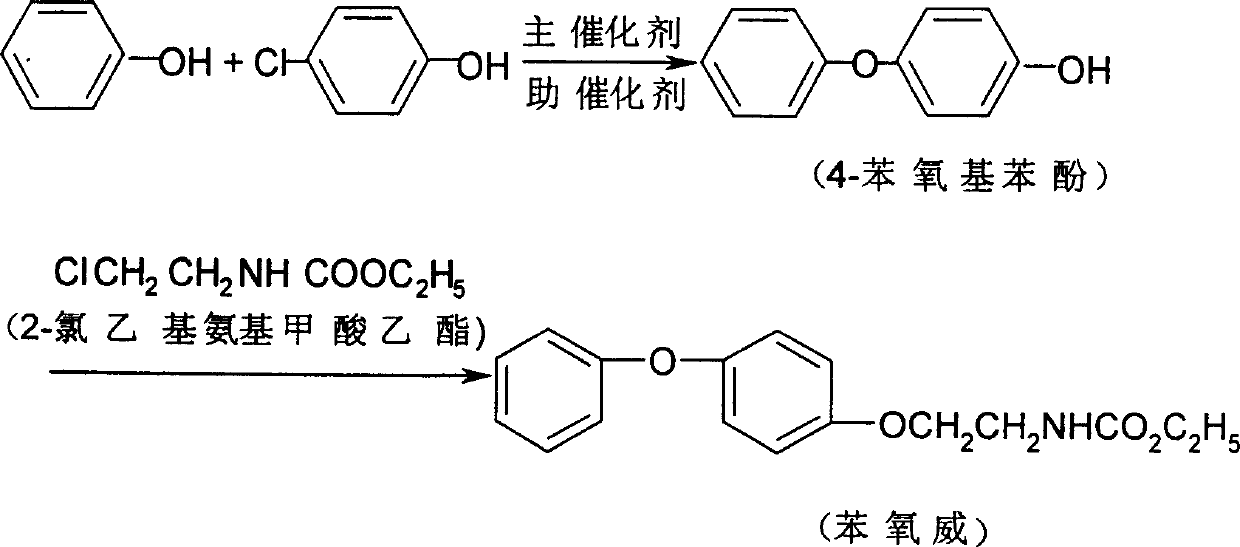

A process for synthesizing fenoxycarb by use of composite catalyst incldues such steps as reaction between phenol and p-chlorophenol under action of copmosite catalyst in alkaline condition to obtain 4-phenoxyphenol, and reating on 2-ethyl chloroethylformate. Said composite catalyst is also disclosed.

Description

technical field The present invention relates to a kind of new technology of synthesizing fenoxycarb, specifically relate to a kind of new technology that adopts composite catalyst to synthesize fenoxycarb. Background technique Fenoxycarb, also known as fenoxycarb and fenoxycarb, has a chemical name of 2-(p-phenoxyphenoxy)ethyl carbamate, which was developed by Ciba-Geigy in Switzerland in 1982. It is the only juvenile hormone pesticide with broad-spectrum insecticidal effect successfully developed so far. The pesticide has the advantages of low toxicity, high efficiency, broad spectrum, not easy to produce resistance, and does not pollute the environment. Especially it has special effects on pests that have developed resistance to conventional pesticides such as pyrethroids and organophosphorus, such as diamondback moth, beet armyworm, cabbage caterpillar, cabbage aphid, apple yellow aphid, etc. It is an ideal medicine for pollution agricultural production. Fenoxycarb ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/72B01J31/02C07C269/00C07C271/16

Inventor 陆庆宁叶锡纯周祖新周长结

Owner PILARQUIM SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com