Froming method of particle, forming method and formed body obtained by the method

A powder and granular technology, applied in the field of powder and granular forming devices, can solve the problems of poor rectification performance, low strength, short brush life, etc., and achieve the effect of increased forming density and roughly uniform forming density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

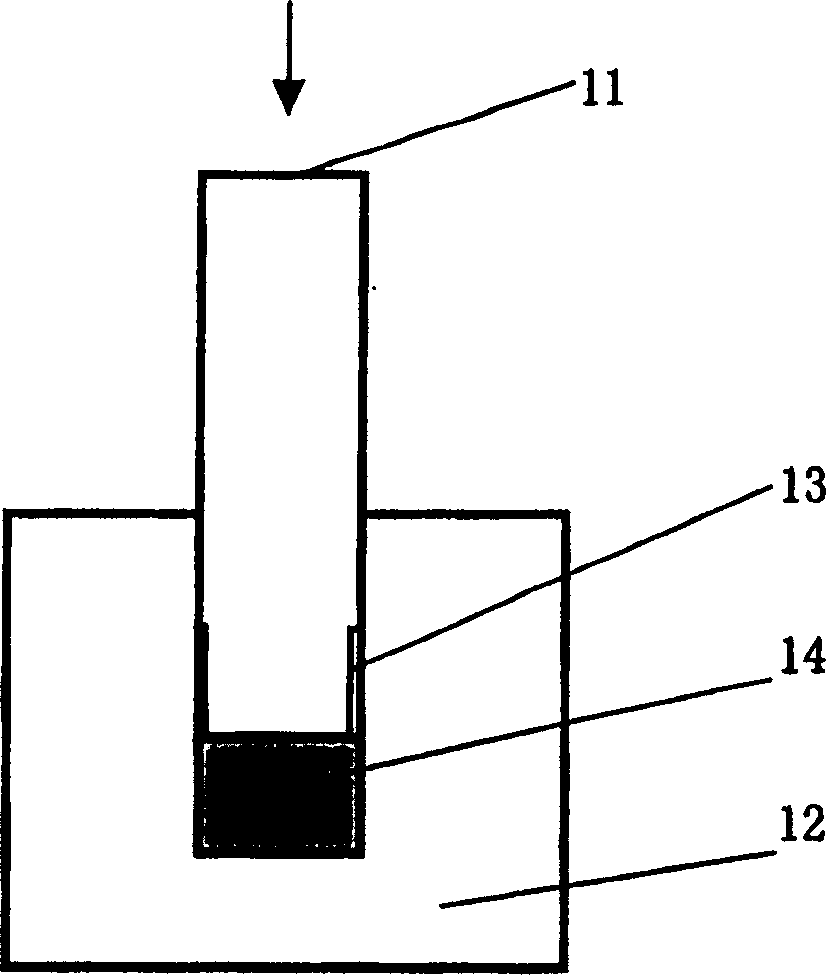

Embodiment 1

[0045] Add 25 parts by weight of thermosetting resin to 100 parts by weight of artificial graphite powder with an average particle diameter of 40μm, and pulverize the agitated mixture to an average particle diameter of 200μm to prepare powder for resin-bonded carbon brush molding. Mitochondria. The continuous automatic powder press molding device described in the specific embodiment molds four such carbonaceous molding powders and granules at a time.

Embodiment 2

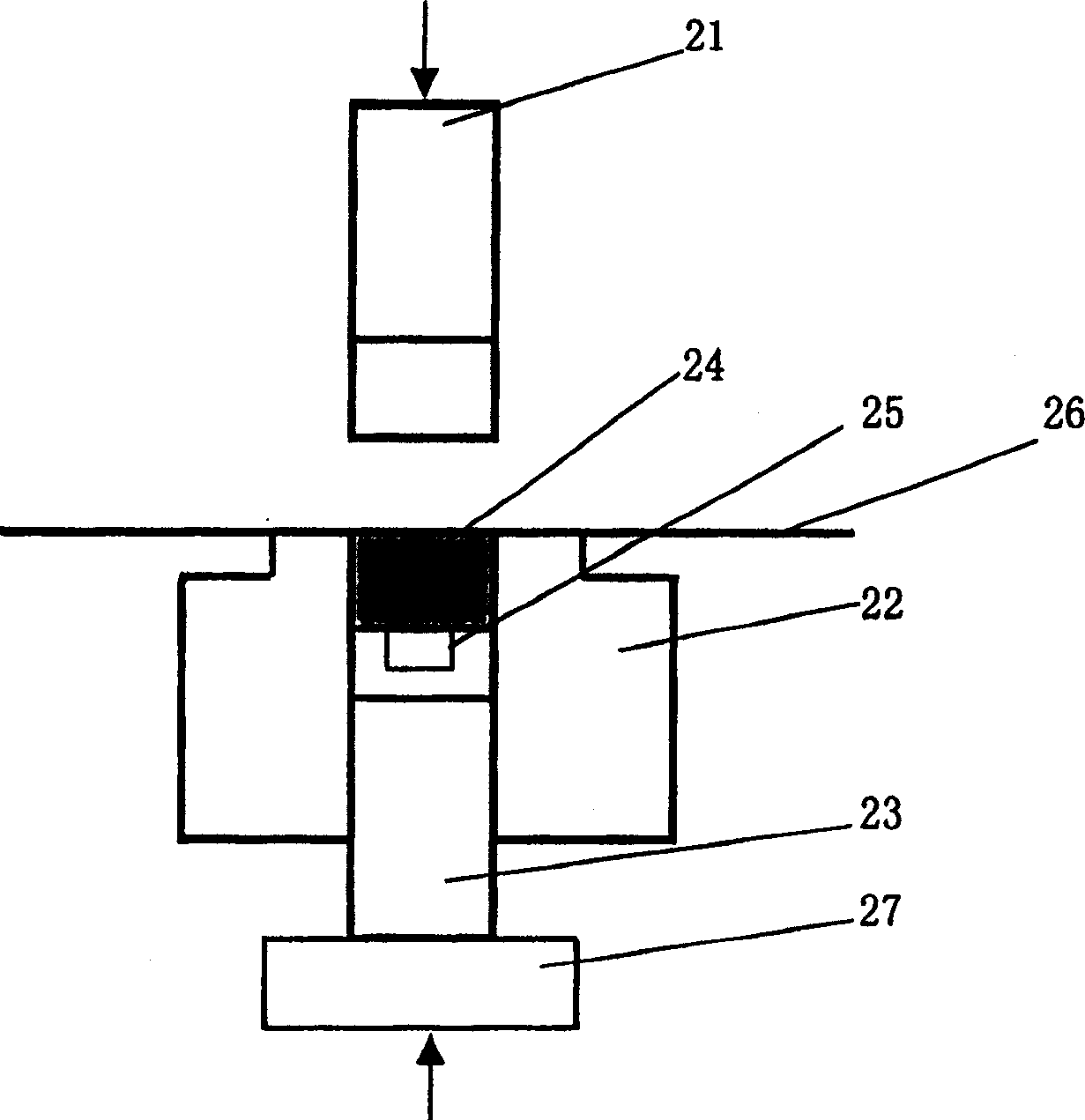

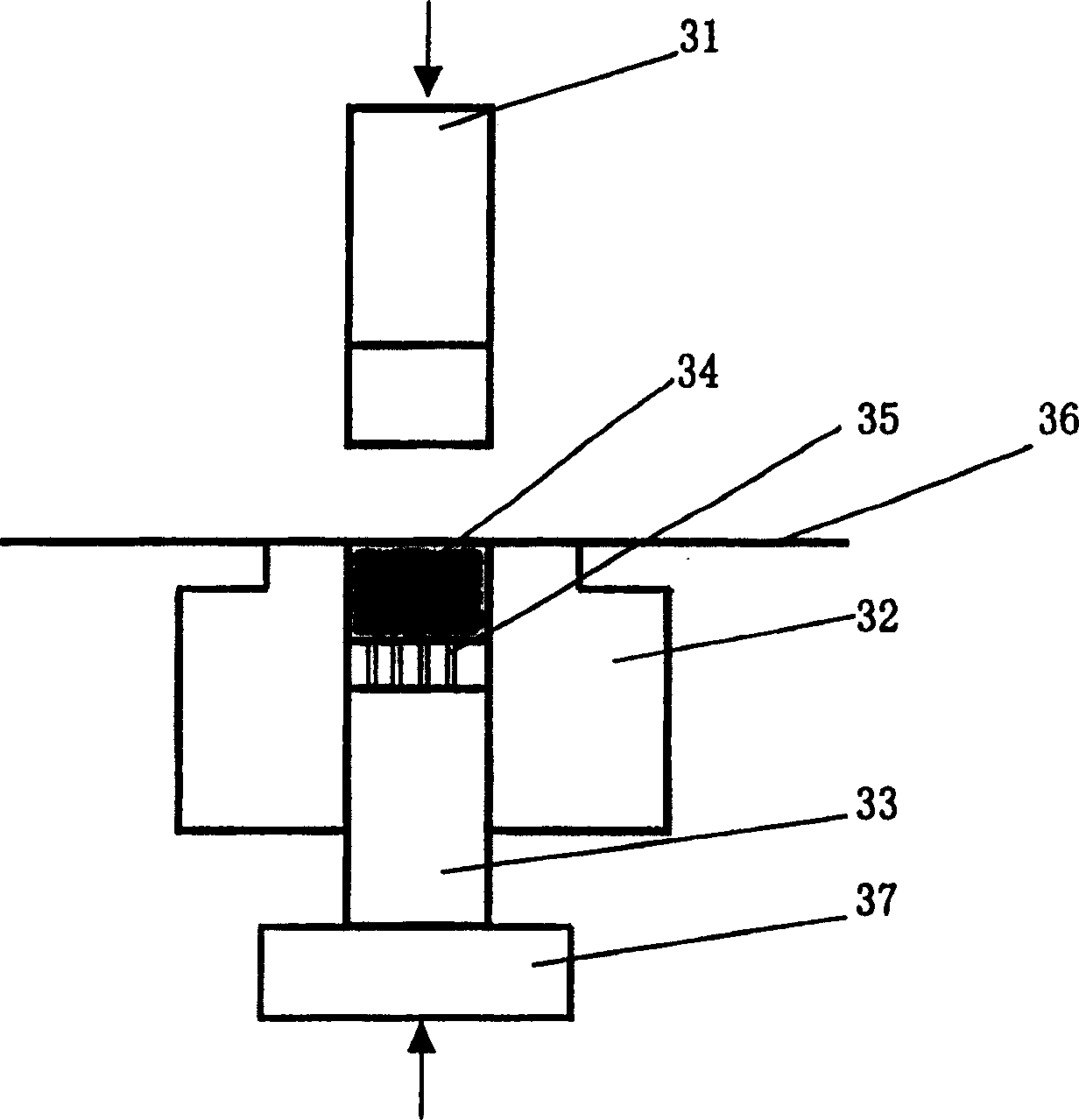

[0047] A continuous automatic powder press molding device with the above U-shaped groove formed not only on the lower punch but also on the upper punch was produced, and four resin-bonded carbon brush powders used in Example 1 were molded at a time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com