Electro-mechanic mixed driving system of automobile

A hybrid drive and electromechanical technology, applied in the direction of power devices, vehicle components, pneumatic power devices, etc., can solve the problems of increased cost, high cost of the second inverter, high cost of the inverter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

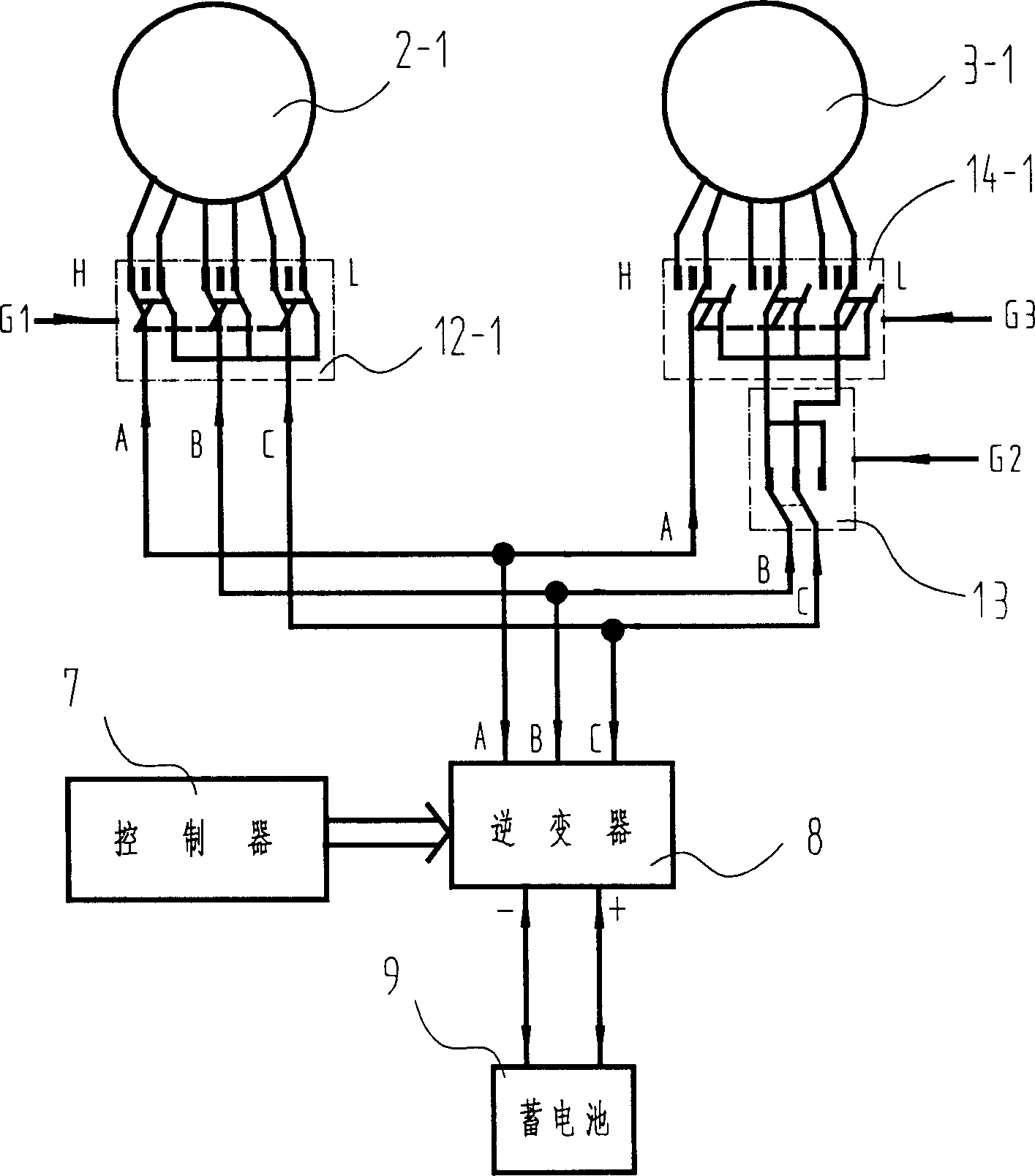

[0043] see figure 1 , which is an example where both the starter motor and the drive motor are multi-speed multi-phase AC motors. The system includes an engine 1, a starter motor 2, and a drive motor 3, the output shaft 11 of the engine is connected with the rotor shaft of the starter motor 2, the rotor shaft 4 of the drive motor is connected with the input shaft of the differential 5, and the differential 5 Link with the axle of a pair of front wheels or a pair of rear wheels 6 respectively. The system also includes a controller 7, inverter 8 and storage battery 9, the signal input end of the controller 7 is provided with the signal input interface of the engine speed sensor 15, the driving motor speed sensor 16 and the driving signal sensor 17, wherein the driving The signal sensor 17 should include an acceleration (accelerator pedal) sensor 17-1, a deceleration (brake pedal) sensor 17-2, a start (start lock) sensor 17-3 and an advance / retreat (advance and retreat joystick)...

Embodiment 2

[0054] see you again figure 1 , in order to improve the transmission efficiency of the system of the first embodiment, a clutch 10 can be added between the rotor shaft of the starter motor 2 and the rotor shaft of the drive motor 3 , and the clutch 10 is controlled by the controller 7 on and off. This clutch is only used on the high-speed gear (third gear), and its control process is: when the vehicle accelerates on the third gear, the controller 7 detects that the driving motor and the engine speed are consistent (that is, the input shaft of the clutch is the same as the output shaft speed). , are all 3000 rpm), that is, the control clutch 10 is closed, so that the engine and the driving motor can jointly drive the vehicle. At this time, the power of the engine is directly transmitted to the wheels, which can improve the transmission efficiency of the system; when the vehicle enters When driving at a constant speed, the engine drives the vehicle independently, while the start...

Embodiment 3

[0056] see Figure 6 In order to increase the flexibility of the system transmission ratio design in the above-mentioned embodiment 2 system, a single-stage gear transmission 18 can be added at the joint between the output shaft of the clutch 10 and the rotating shaft of the drive motor 3 . For example: for a system using a 2+1 two-speed drive motor, when the single-stage gear transmission 18 is not added, the transmission ratio of the third gear is 4 times that of the first gear; if the single-stage gear transmission is added 18. The three-speed system is equivalent to adding a speed gear to become a four-speed system, and if the transmission ratio R of the transmission is set to 10 9, the transmission ratio of the fourth gear is the first gear transmission ratio 4R (4.44) times, where R = 10 / 9 = 1.111. It can be seen that by correspondingly changing the speed ratio of the single-stage gear transmission 18, the speed ratio of the 2+1 two-speed drive motor system can be flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com