Self-support cooling air blowing apparatus

A technology of blowing device and cooling air flow, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of high cost, easy aging, short service life, etc., to prolong the service life and prevent high temperature aging. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

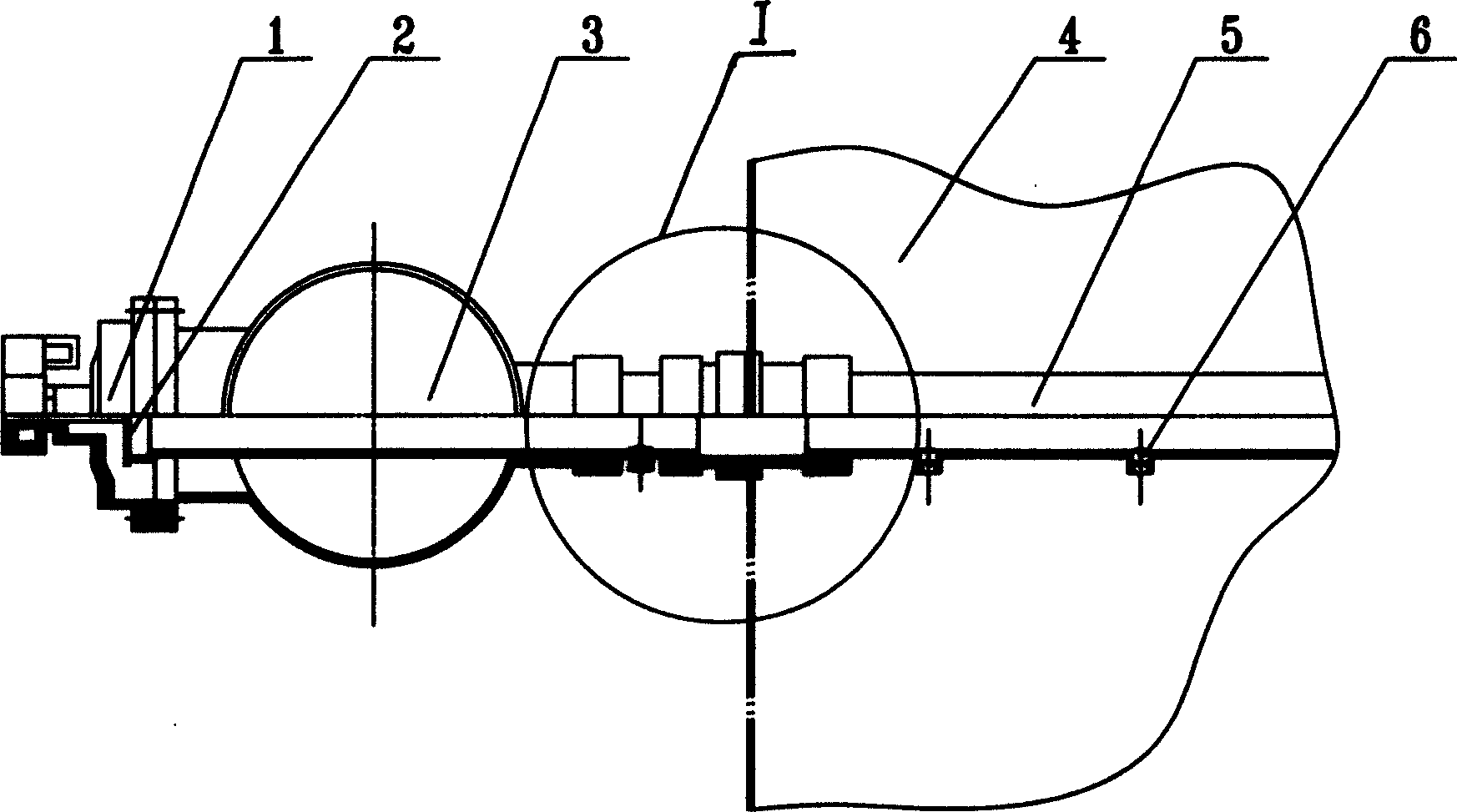

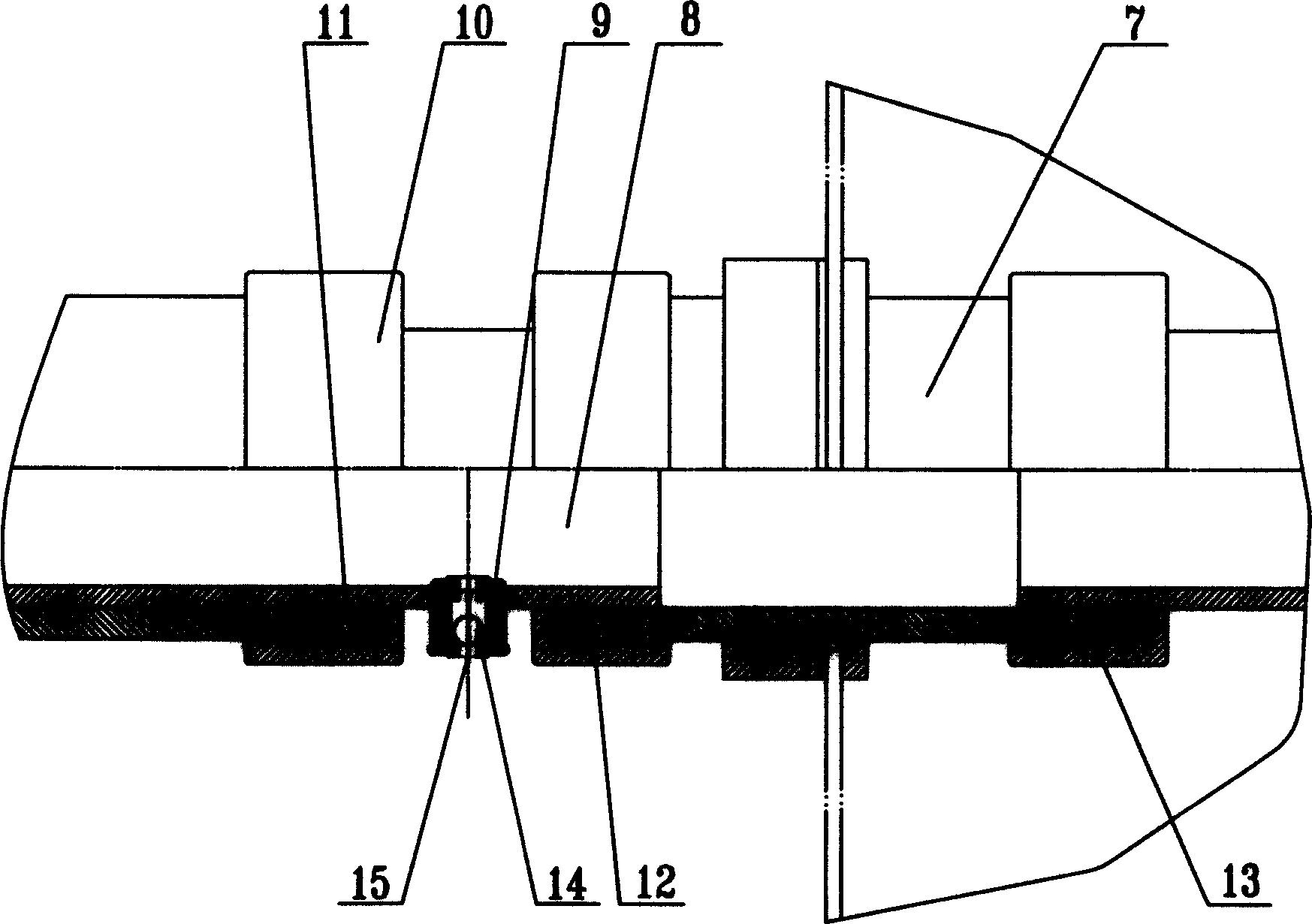

[0013] see figure 1 and figure 2 , a self-cooling air blowing device, is to insert one end of the connecting pipe 8 outside the box from the connecting pipe end of the gas storage tank 3, and connect with the pulse valve 1 containing the diaphragm 2 connected to the flange end of the gas storage tank 3, After adding the "O" type sealing ring 11 at the port position of the connecting pipe end of the gas storage tank 3, lock it with the connecting pipe 8 outside the box with the pipe sealing nut 10. Then insert the other end of the connecting pipe 8 outside the box into the wall-through connection pipe 7 installed on the box body 4, lock the box outer nut 12 on the wall-through connection pipe 7, between the pipe sealing nut 10 and the box ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com