Ceramic package light-emitting diode an dits package method

A light-emitting diode and ceramic packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation, temperature shock resistance, and poor reliability of SMD LEDs, and achieve strong resistance to high and low temperature shocks , high reliability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

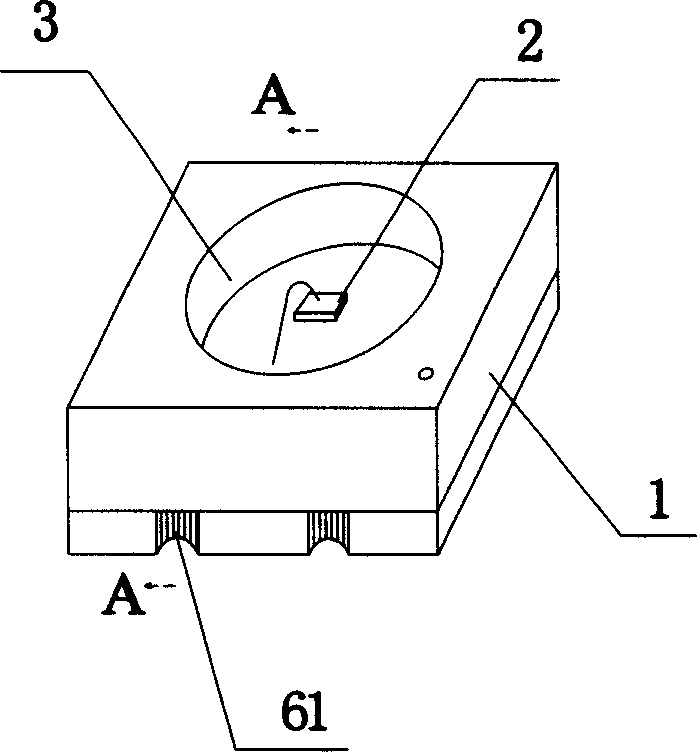

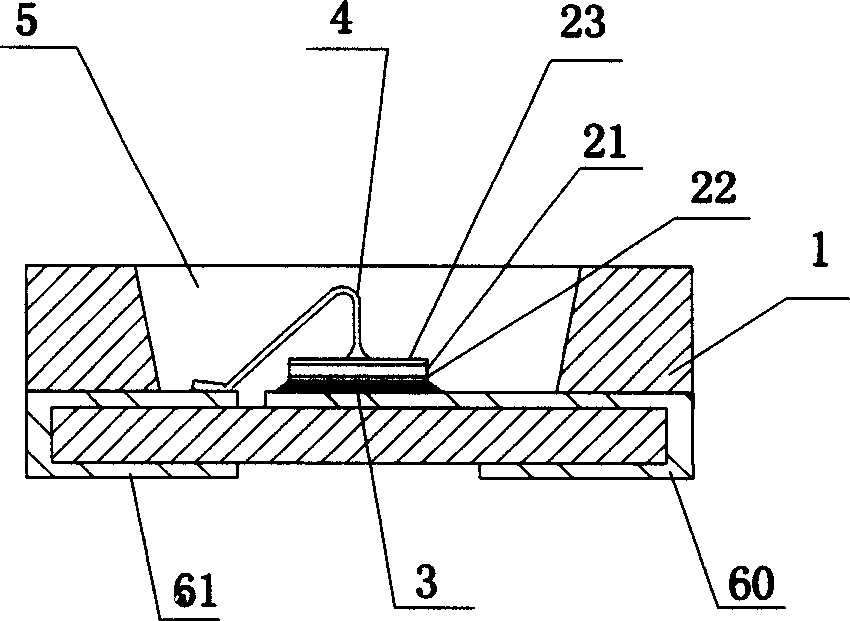

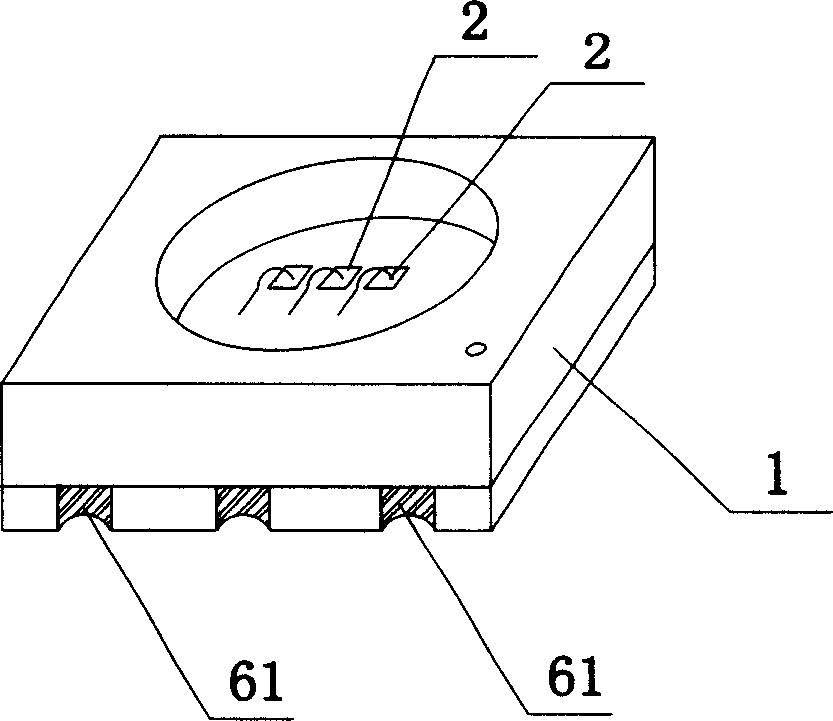

[0022] Such as figure 1 Shown is a perspective view of the present invention. and combine figure 2 shown. The SMD LED of the present invention mainly includes a ceramic substrate 1, an LED chip 2 and a packaging body 5 containing the LED chip. The ceramic substrate 1 has a roughly square structure, and a recessed encapsulation cavity 3 is provided on its upper part. The inner wall of the encapsulation cavity 3 is an outwardly inclined arc surface, forming a reflective circle. The LED chip is installed in the package cavity 3, and two electrodes, ie, the first electrode 60 and the second electrode 61, are arranged in the package cavity of the substrate, and the two electrodes respectively extend to the bottom of the ceramic substrate.

[0023] The LED chip 2 includes an LED chip main body 21 , a lower electrode 22 arranged under the LED chip main body 21 , and an upper electrode 23 arranged on the upper surface of the LED chip main body 21 . The lower electrode 22 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com