Single eye visual sensor for welding robot and its hand-eye relation quick marking method

A welding robot and monocular vision technology, applied in the direction of manipulator, welding equipment, auxiliary welding equipment, etc., can solve the problem of not being able to meet the simple and fast calibration, meet the needs of actual production work, simplify the calculation amount and complexity, and maximize the use. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

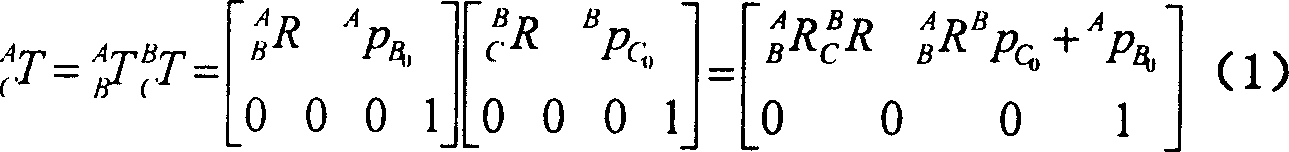

Method used

Image

Examples

Embodiment Construction

[0015] Such as figure 1 As shown, the welding robot monocular vision sensor of the present invention includes: a miniature CCD camera 1 , a light reduction and filtering system 2 , a motor drive system 3 and a mounting bracket 4 . The connection relationship is as follows: the miniature CCD camera 1, the light reduction and filter system 2 and the motor drive system 3 are all arranged on the mounting bracket 4, and the light reduction and filter system 2 includes a light reduction lens 5, a filter lens 6 and a lens holder 7. The movable connecting rod 8, the driving arm 9, the dimming lens 5 and the filter lens 6 are overlapped and arranged on the lens holder 7, and are connected with the driving arm 9 through the movable connecting rod 8, and the driving arm 9 is directly connected to the motor drive system. The output shaft of the deceleration device 11 is connected, and can be driven by the output shaft to rotate forward / reversely; the motor drive system 3 includes a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com