Special working device for automatic cold-forging forming machine

A technology of working device and forming machine, applied in the direction of driving device of forging press, etc., can solve the problem of using automatic cold forging forming machine that has never been sold, and achieve continuous mass production, simple layout, and the structure of parts and mutual interaction. The effect of simple connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

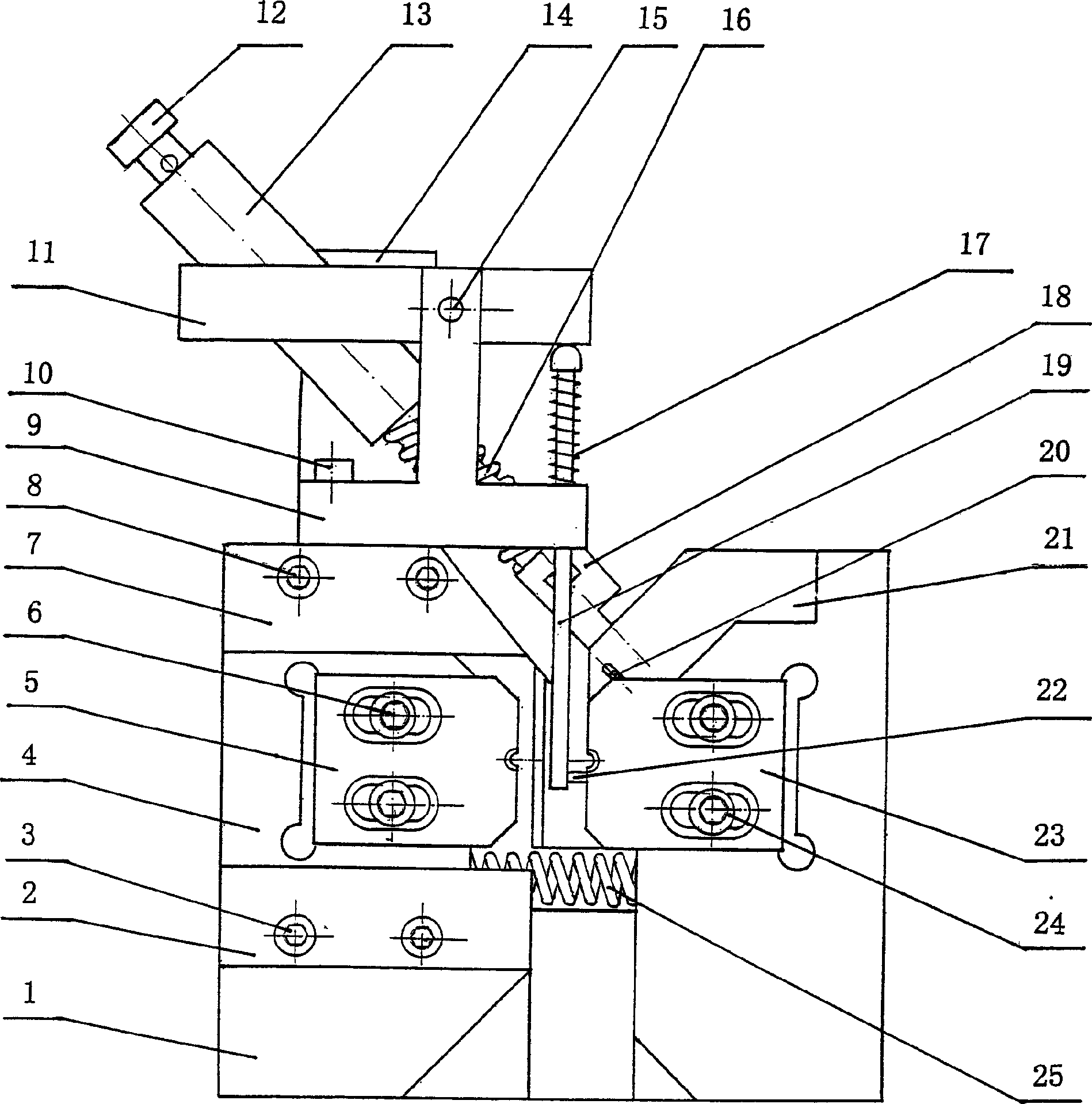

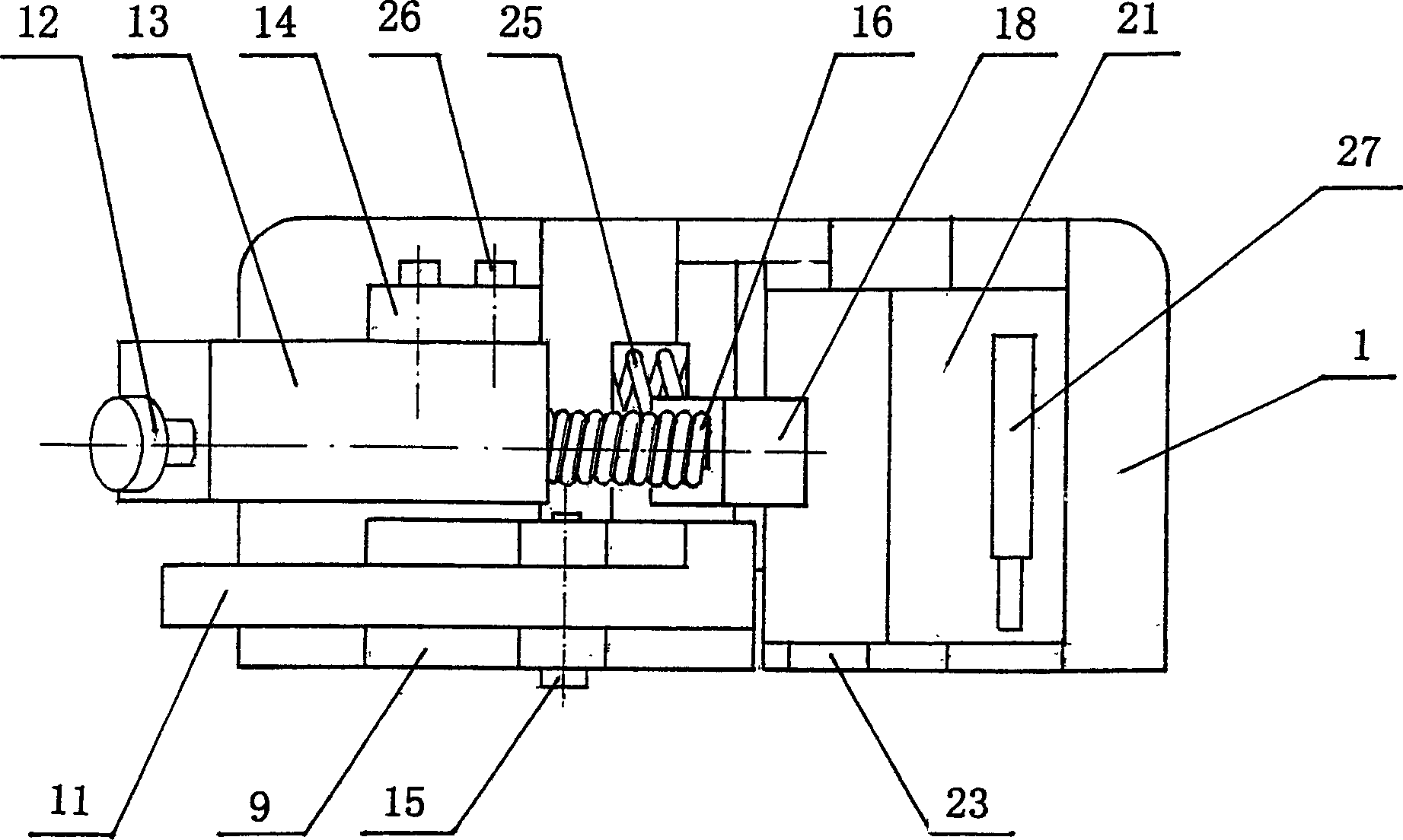

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

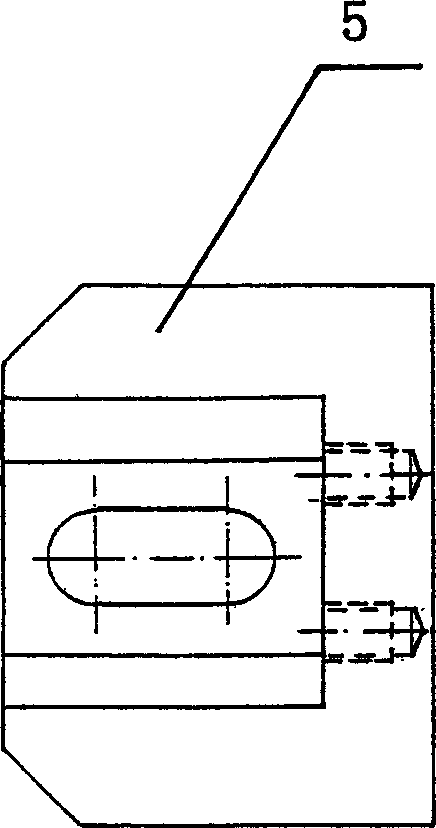

[0024] Such as figure 1 , figure 2 As shown, a slideway is provided on one side of the base 1, the slideway is equipped with a sliding module seat 4, the upper block 7 is fixed on the base 1 by two bolts 8, and the lower block 2 is fixed by two bolts 3 On the base 1, the sliding module seat 4 is limited to move horizontally in the slideway. A sliding module 5 is fixedly installed in the sliding module seat 4 with two bolts 6 . On the other side of the base 1 corresponding to the sliding module 5 , a fixing module 23 is fixedly installed with two bolts 24 . The inner surface of the sliding module 5 and the inner surface of the fixed module 23 respectively have semicircular arc grooves corresponding to each other, and a lower platform 22 tangent to the arc groove is also provided in the middle section of the fixed module 23 arc groove. The mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com