Device for producing flour wrapper

A technology for producing equipment and dough, applied in the directions of dough extruder, dough sheeter/rolling machine/rolling pin, etc., can solve the problem of inability to make pulpy starch dough, inability to achieve industrialized mass production, and inability to apply catering Demand and other issues, to avoid burnout of dry burning equipment, ensure full utilization and operational safety, and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

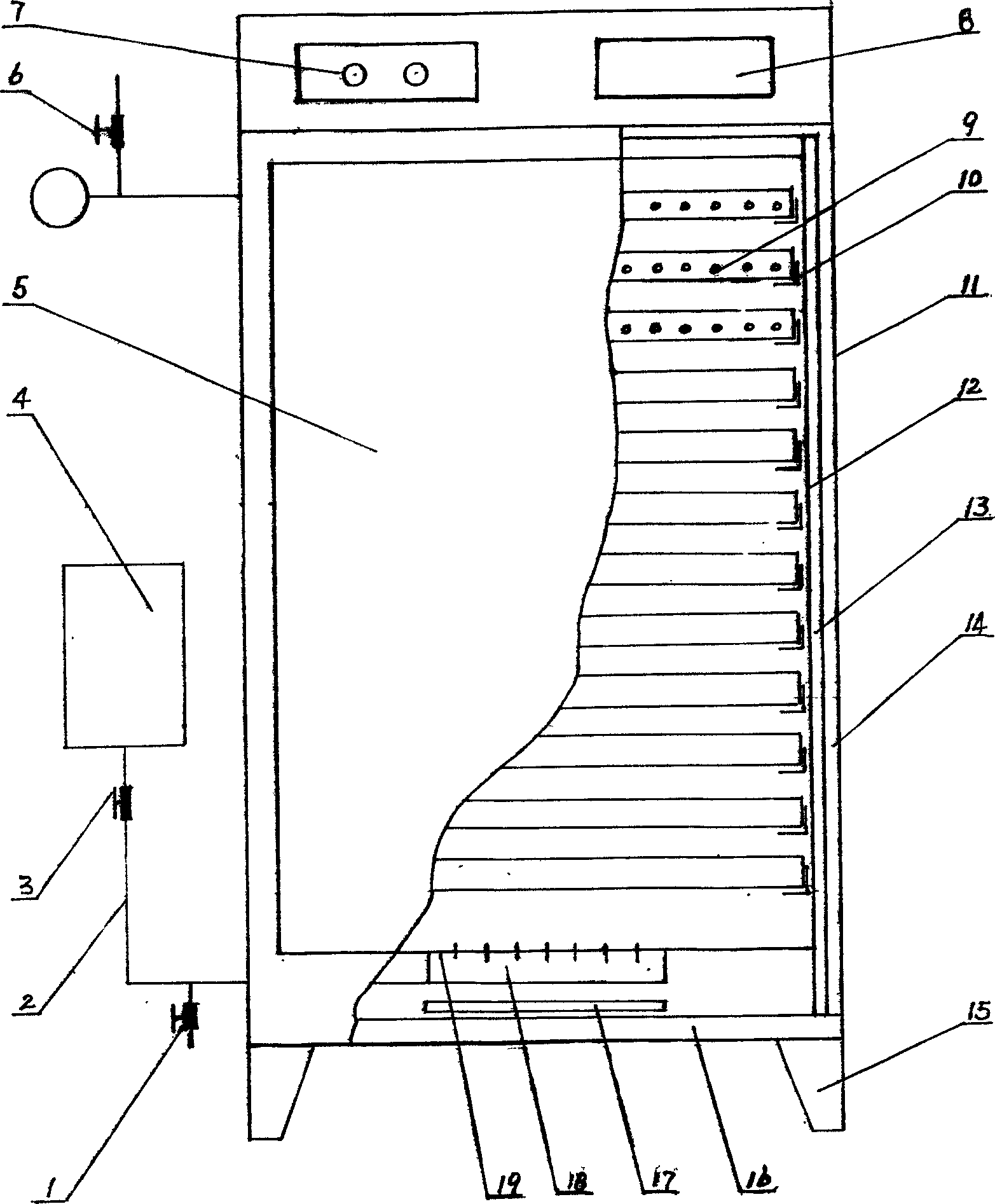

[0007] Embodiment 1: with reference to attached figure 1 . Dough production equipment, the side of the box body 11 is provided with a plurality of brackets 10 and the steaming tray 9 is located on the brackets 10, and there are steam conduction holes around the steaming tray. The electric heating steam generator 17 is located at the bottom of the box body 11. The water tank 4 communicates with the water tank 18 in the electric heating steam generator 17 through the water inlet pipe 2 and the control valve box doors 1 and 3. The box door 5 of the box body is connected to the box body 11. There is a tight fit and can be opened or closed. Casing 11 and chamber door 5 are made of case inner plate 12, insulation layer 16 and case outer plate 20, and insulation layer 16 is positioned at case inner plate 12 and case outer plate 20. Casing 11 top is provided with safety valve 6, and the exhaust hole of safety valve 6 is connected with casing cavity. The casing 11 is provided with a...

Embodiment 2

[0008] Embodiment 2: On the basis of Embodiment 1, an electrically heated superheated steam heater 13 is installed on the cavity wall of the box body 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com