Optical fibre connector face geometrical parameter measuring instruments

A fiber optic connector and geometric parameter technology, applied in the field of optical fiber connector end face geometric parameter measuring instrument, can solve the problem of difficult to ensure the eccentricity of the vertex of the spherical surface, the measurement accuracy of the height of the optical fiber and the inclination angle of the end face, the difficulty of accurately determining the center of the optical fiber, and the low accuracy, etc. problem, to achieve the effect of avoiding the transmission of errors, ensuring robustness, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

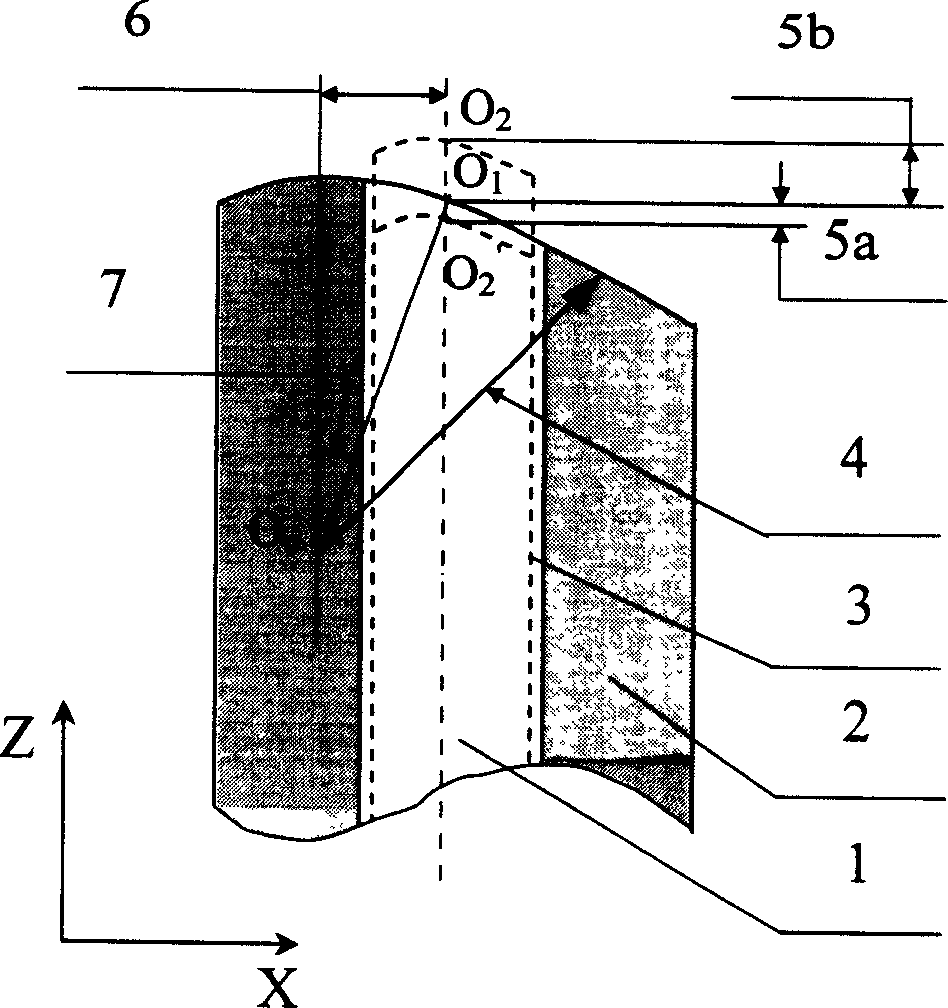

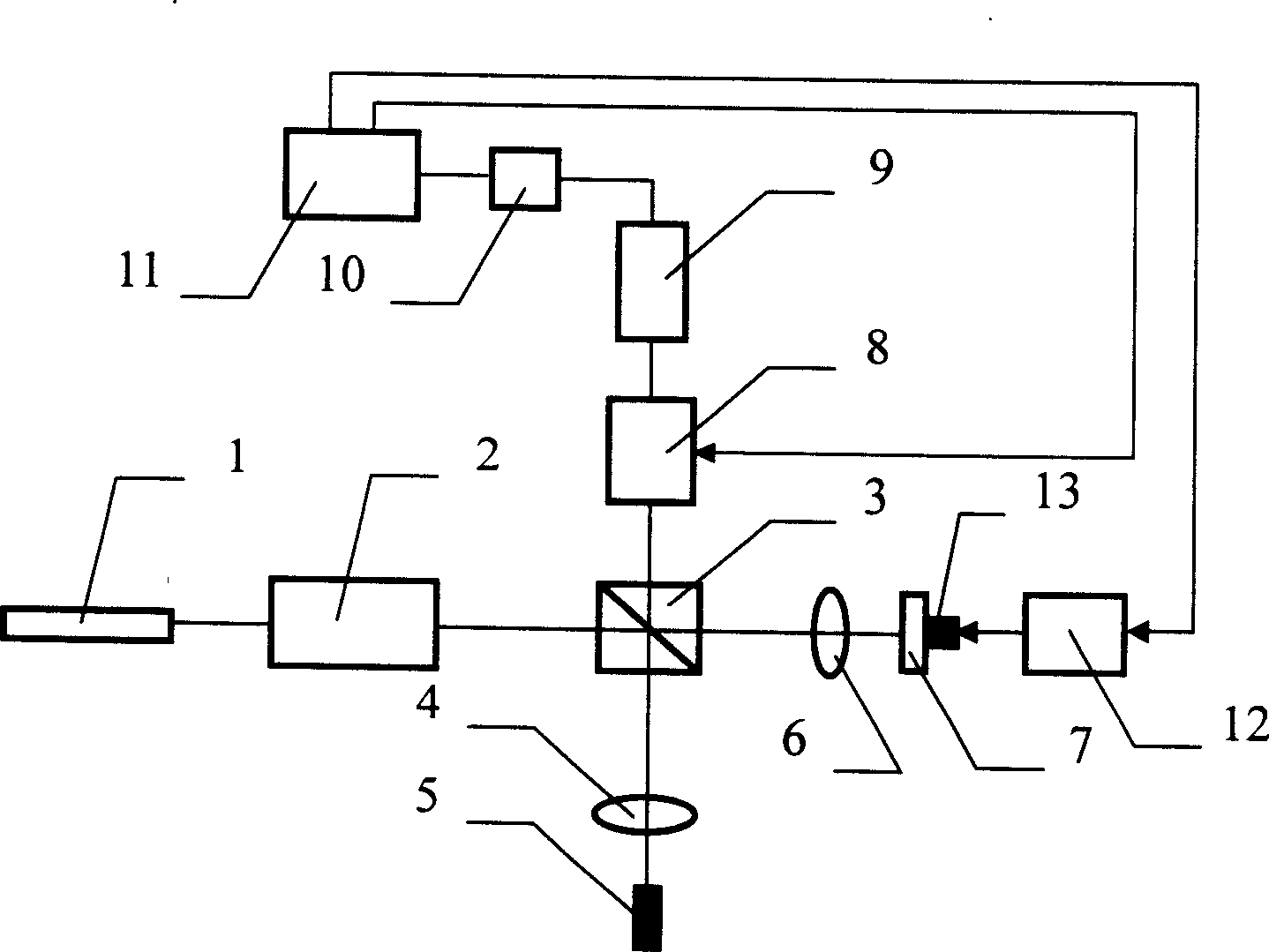

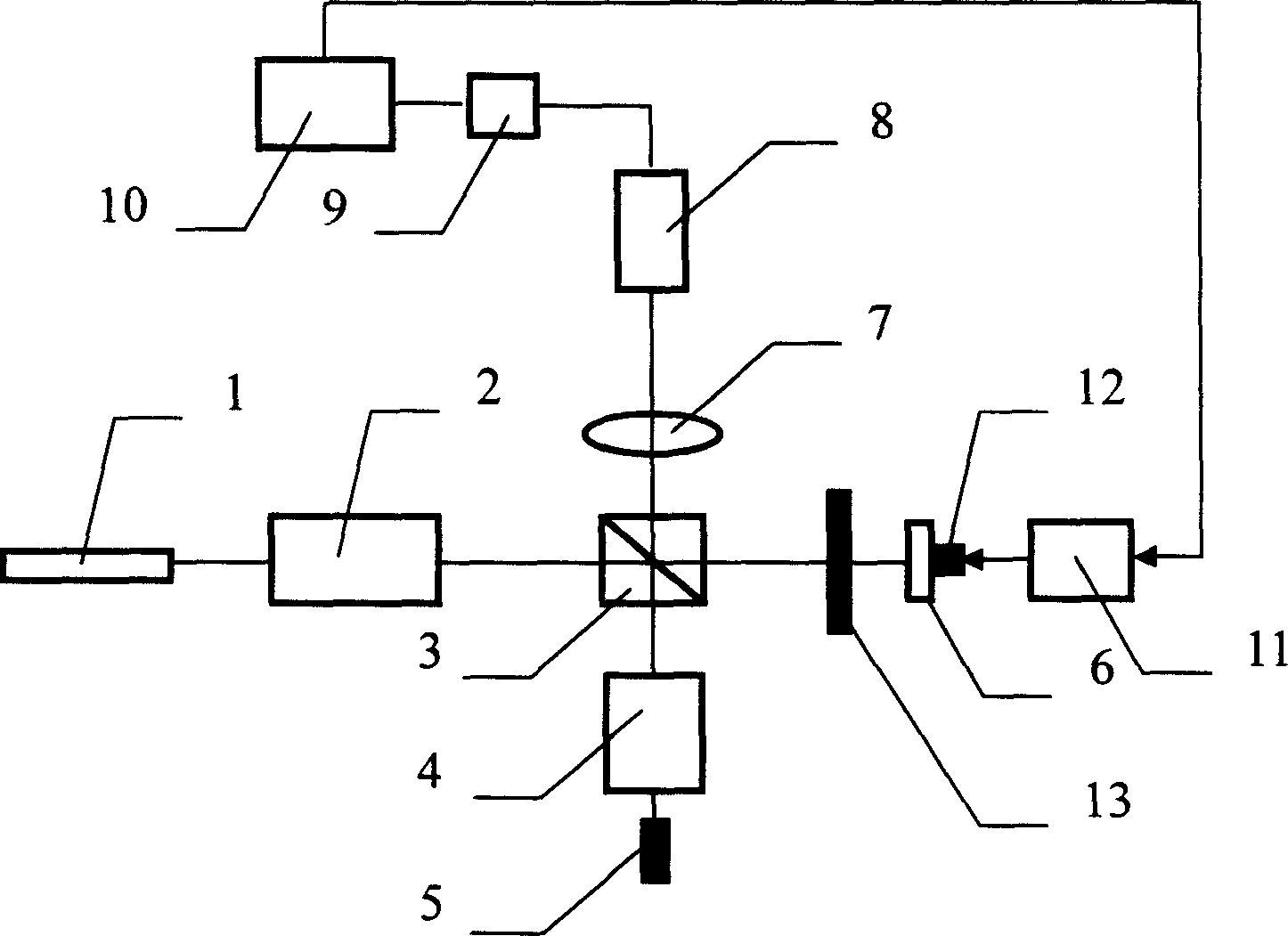

[0042] see first image 3 , image 3 It is a structural schematic diagram of the optical fiber connector end face geometric parameter measuring instrument of the present invention. As can be seen from the figure, the optical fiber connector end face geometric parameter measuring instrument of the present invention adopts a Twyman-Green interferometer structure, including a light source 1, and a collimating beam expander system 2 is sequentially arranged on the same optical axis along the forward direction of the emitted light beam of the light source 1, and is divided into two parts. A beam filter 3, a shutter 13, and a reference plane mirror 6 bonded on a piezoelectric ceramic 12. In the direction passing through the center of the beam splitter 3 and perpendicular to the light beam emitted by the light source 1, one end of the beam splitter 3 is provided with the optical fiber connector 5 and the optical system 4 to be tested, and the other end is provided with a lens 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com