Preparing method for titanium dioxide fibre

A titanium dioxide and fiber technology, applied in the field of functional fiber materials, can solve the problems of complex spinning solution preparation process, harsh reaction conditions, expensive raw materials, etc., and achieve the effects of high strength, reduced synthesis cost, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Embodiment 1: the preparation method of titanium dioxide short fiber, the steps are as follows:

[0046] (1) According to the ratio of titanium tetrachloride: distilled water: acetylacetone: triethylamine=1mol: 3mol: 1mol: 4mol, measure 40.0ml, 20.0ml, 37.3ml and 40.0ml of the above four liquid reagents (analytical pure) respectively. 202.1ml, and according to the relationship that the dilution factor of titanium tetrachloride is 5 times, the dilution factor of distilled water is 5 times, the dilution factor of acetylacetone is 3 times, and the dilution factor of triethylamine is 3 times. Reagents were diluted in 200.0ml, 100.0ml, 112.0ml and 606.5ml of four parts of methanol, under the condition of stirring and 10°C, the methanol dilution of distilled water was added dropwise to the methanol dilution of titanium tetrachloride, and the dropwise Then continue to stir for 20 minutes to obtain the mixed diluent A, and at the same time directly mix the methanol diluents of a...

Embodiment 2

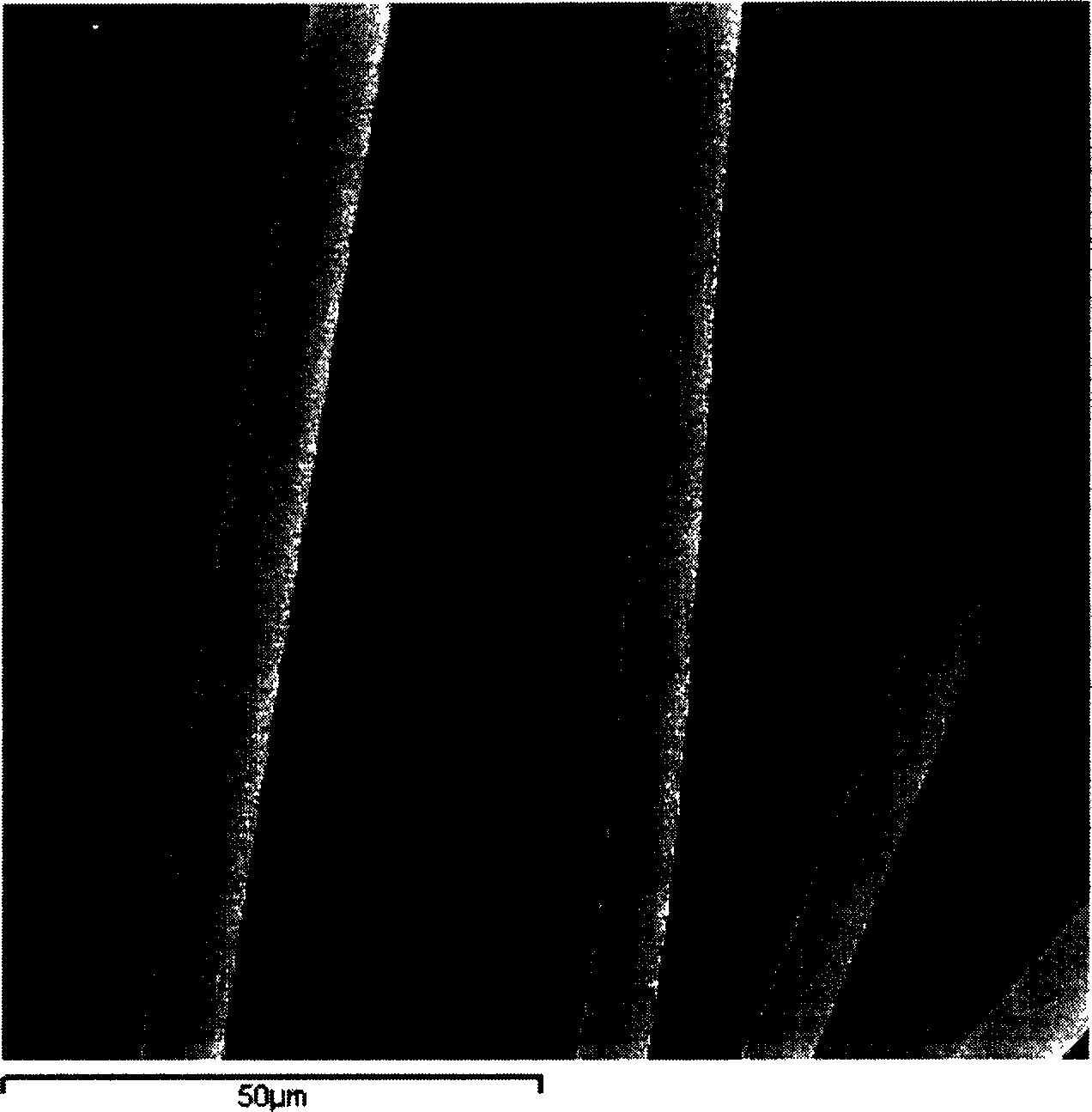

[0050] Embodiment 2: the preparation method of titanium dioxide continuous fiber

[0051] As described in Example 1, the difference is that the viscosity of the spinning solution in step (2) is adjusted to 80 Pa·s (20°C), and dry spinning is used in step (3) to obtain continuous precursor fibers, that is, to spin The silk liquid is moved into the liquid material tank in the dry spinning device, vacuum defoamed for 10 minutes, and the temperature is 10 °C and the relative humidity is 20%, and the pressure of 1.0 MPa is applied to the spinning liquid by means of cylinder nitrogen, so that It is sprayed from a niobium-tantalum alloy spinning plate with a hole diameter of 0.10 mm, and is drawn and drum-wrapped to obtain transparent and orderly continuous precursor long fibers with almost arbitrary lengths. In step (4), the continuous The precursor fiber is placed in a program-controlled furnace, subjected to 80°C-600°C atmospheric pressure water vapor heat treatment for 24 hours, ...

Embodiment 3

[0052] Embodiment 3: the preparation method of titanium dioxide short fiber

[0053] As described in Example 1, the difference is that the ratio of titanium tetrachloride: distilled water: acetylacetone: triethylamine in step (1) is changed to 1mol: 4.5mol: 1.3mol: 4mol, that is, measure the above four kinds of Liquid reagents (analytical pure) are 40.0ml, 30.0ml, 48.5ml and 202.1ml, and the dilution factor of titanium tetrachloride is 4 times, the dilution factor of distilled water is 4 times, and the dilution factor of acetylacetone is 2.5 times. The dilution factor of ethylamine is 3 times. Dilute each of the above four reagents into four parts of methanol of 160.0ml, 120.0ml, 121.3ml and 606.5ml respectively. Add dropwise to the methanol dilution of titanium tetrachloride, continue to stir for 15 minutes after the drop is complete, to obtain a mixed dilution A, and at the same time directly mix the methanol dilutions of acetylacetone and triethylamine to obtain a mixed dil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com