Preparation of bisphenols salts

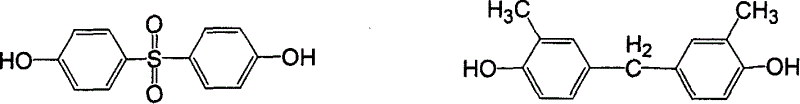

A technology for bisphenol and salt products, applied in the field of di-salt preparation, which can solve the problems of unindustrialization, difficulty in obtaining high-purity bisphenol di-salt monomer, and yield of only 50%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 0.01 mol of bisphenol A, 0.02 mol of NaOH and 200 ml of isopropanol into a 250 ml three-necked flask, pass through nitrogen to remove oxygen, and react at 60°C for 1 hour to obtain a precipitate, filter it under a nitrogen atmosphere, and use 30 ml of Wash twice with hot isopropanol, and reduce pressure at 200° C. for 3 hours to obtain 25.6 g of bisphenol disodium salt with a yield of 94%.

Embodiment 2

[0026] Add 0.01 mol of bisphenol A, 0.02 mol of NaOH and 200 ml of n-propanol into a 250 ml three-necked flask, pass through nitrogen to remove oxygen, and react at 60°C for 3 hours to obtain a precipitate, filter it under a nitrogen atmosphere, and use 30 ml of Wash twice with hot n-propanol, and reduce pressure at 200°C for 3 hours to obtain 25.0 g of bisphenol disodium salt with a yield of 93%.

Embodiment 3

[0028] Add 0.01 mol of bisphenol A, 0.02 mol of NaOH and 200 ml of isobutanol into a 250 ml three-necked flask, pass through nitrogen to remove oxygen, react at 60°C for 1 hour, and obtain a precipitate, filter it under a nitrogen atmosphere, and use 30 ml of Wash twice with hot isobutanol, and reduce pressure at 200°C for 3 hours to obtain 25.6 g of bisphenol disodium salt with a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com