Process for eliminating SOx in flue by activated carbon based adsorbent

An adsorbent and activated carbon technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of no comprehensive utilization of by-product gypsum, secondary pollution, high operating costs, and improve sulfur capacity and use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

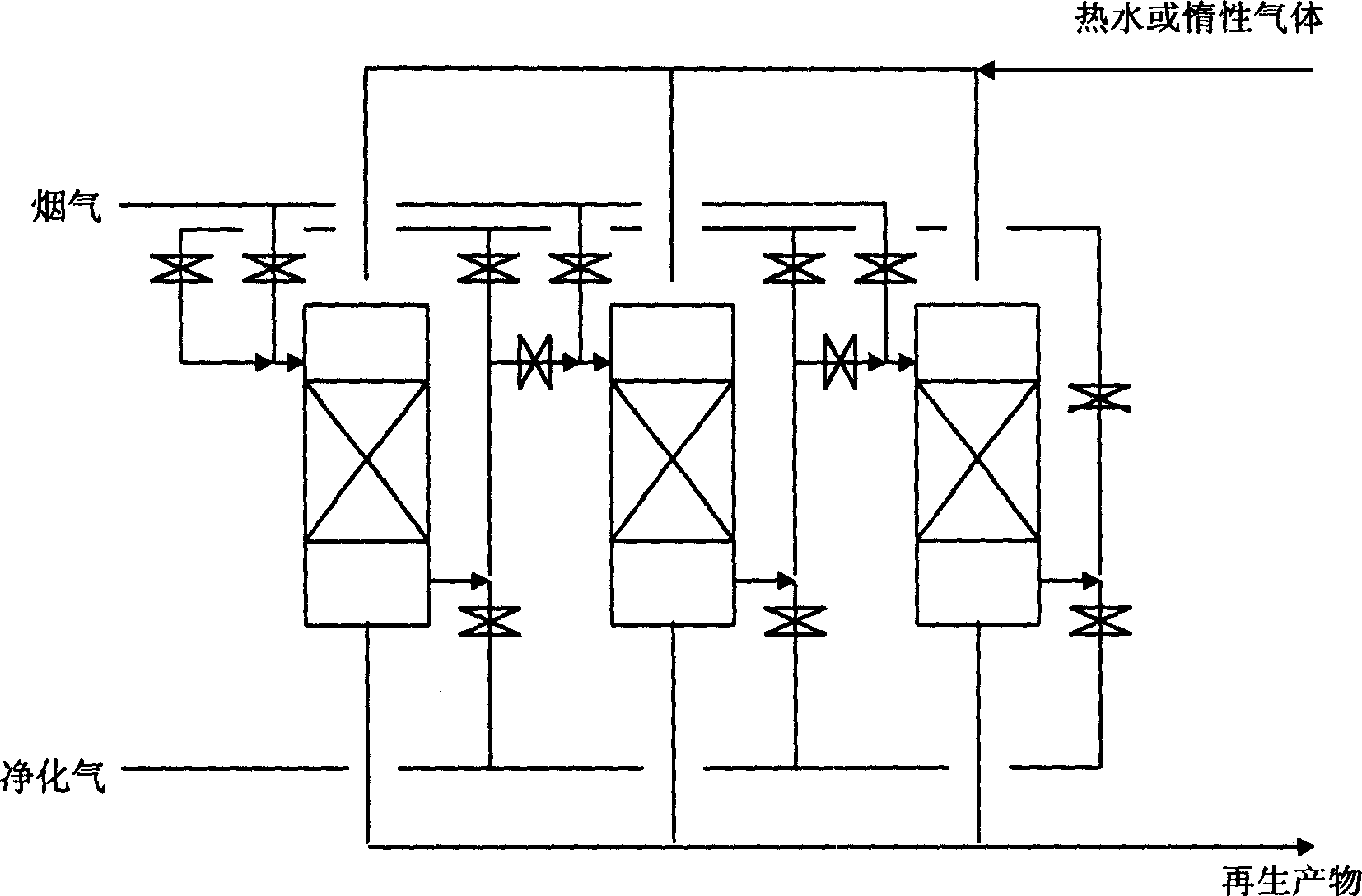

Method used

Image

Examples

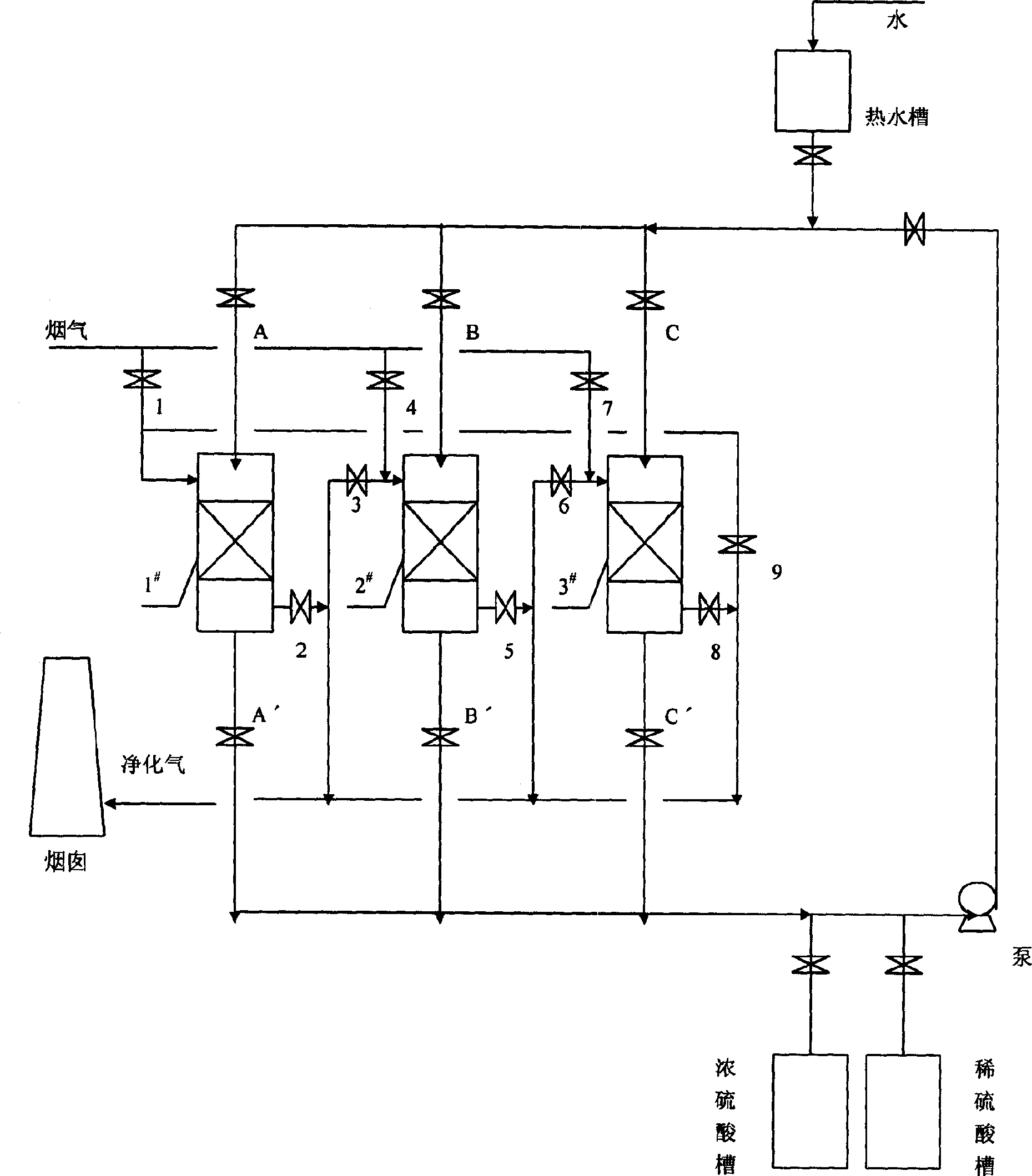

Embodiment 1

[0014] Such as figure 2 As shown, three reaction towers are used to operate individually or in series (parallel). The diameter of the reaction tower is 70mm, the loading volume of each tower is 1 liter, and the weight is 581 grams of active semi-coke adsorbent. The desulfurization temperature is 90 ℃ and the space velocity is 900h. -1 , the flue gas composition is SO 2 800-2600ppm, O 2 9.5-14.8%, CO75-435ppm, the rest is N 2 and CO 2 Under certain conditions, the process operation is as follows: firstly open No. 1 and No. 2 valves, and the flue gas enters into No. 1 # In the desulfurization reaction tower, the desulfurized and purified flue gas enters the purified pipeline through the No. 2 valve and is discharged into the chimney; when 1 # Tower outlet gas SO 2 When the detection exceeds the standard (such as 200ppm), then close the No. 2 valve, and open the No. 3 and No. 5 valves at the same time. At this time, 1 # Desulfurization reaction tower and 2 # Desulfurizat...

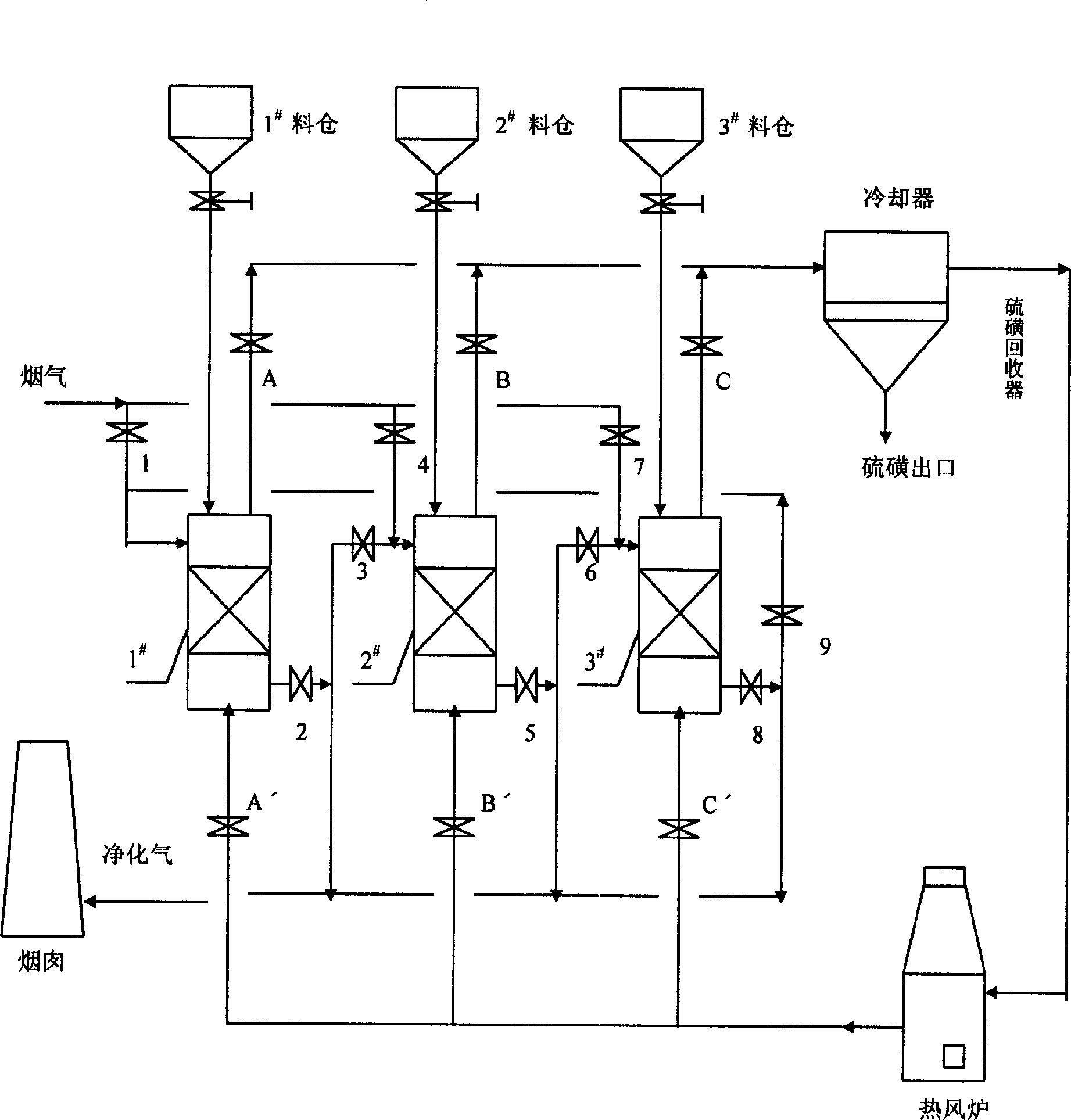

Embodiment 2

[0016] Such as image 3 As shown, three reaction towers are used to operate individually or in series (parallel). The diameter of the reaction tower is 70mm, the loading volume of each tower is 1 liter, and the weight is 581 grams of active semi-coke adsorbent. The desulfurization temperature is 90 ℃ and the space velocity is 900h. -1 , the flue gas composition is SO 2 800-2600ppm, O 2 9.5-14.8%, CO75-435ppm, the rest is N 2 and CO 2 Under certain conditions, the process operation is as follows: firstly open No. 1 and No. 2 valves, and the flue gas enters into No. 1 # In the desulfurization reaction tower, the desulfurized and purified flue gas enters the purified pipeline through the No. 2 valve and is discharged into the chimney; when 1 # Tower outlet gas SO 2 When the detection exceeds the standard (such as 200ppm), then close the No. 2 valve, and open the No. 3 and No. 5 valves at the same time. At this time, 1 # Desulfurization reaction tower and 2 # Desulfurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com