Automatic actuating mechanism for extinguishing and smoke exhausting valve

An actuator, fully automatic technology, applied in fire rescue and other directions, can solve the problems of easy deformation of the tie rod and the inability of the main shaft to rebound, and achieve the effect of overcoming easy deformation, short action time and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

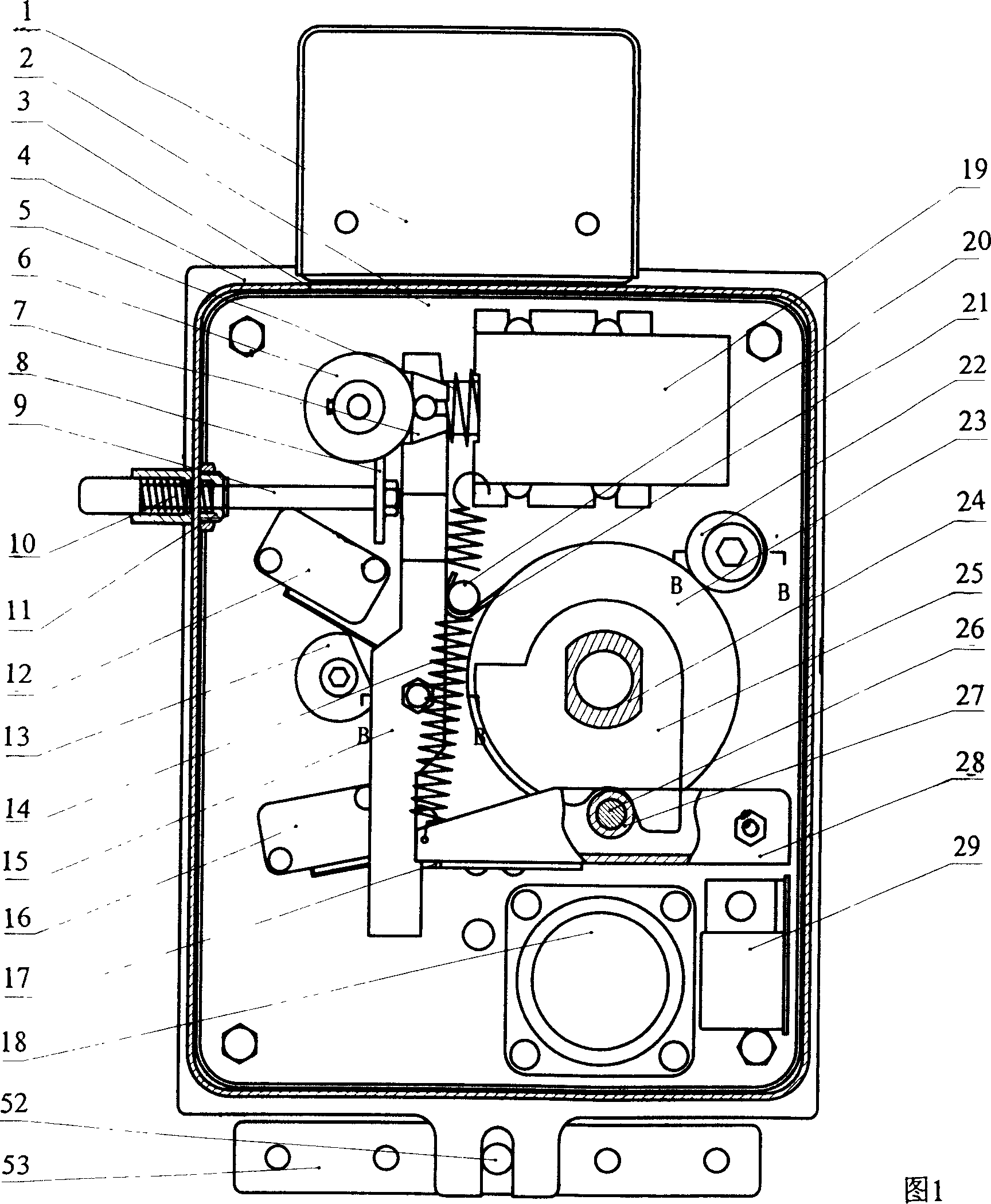

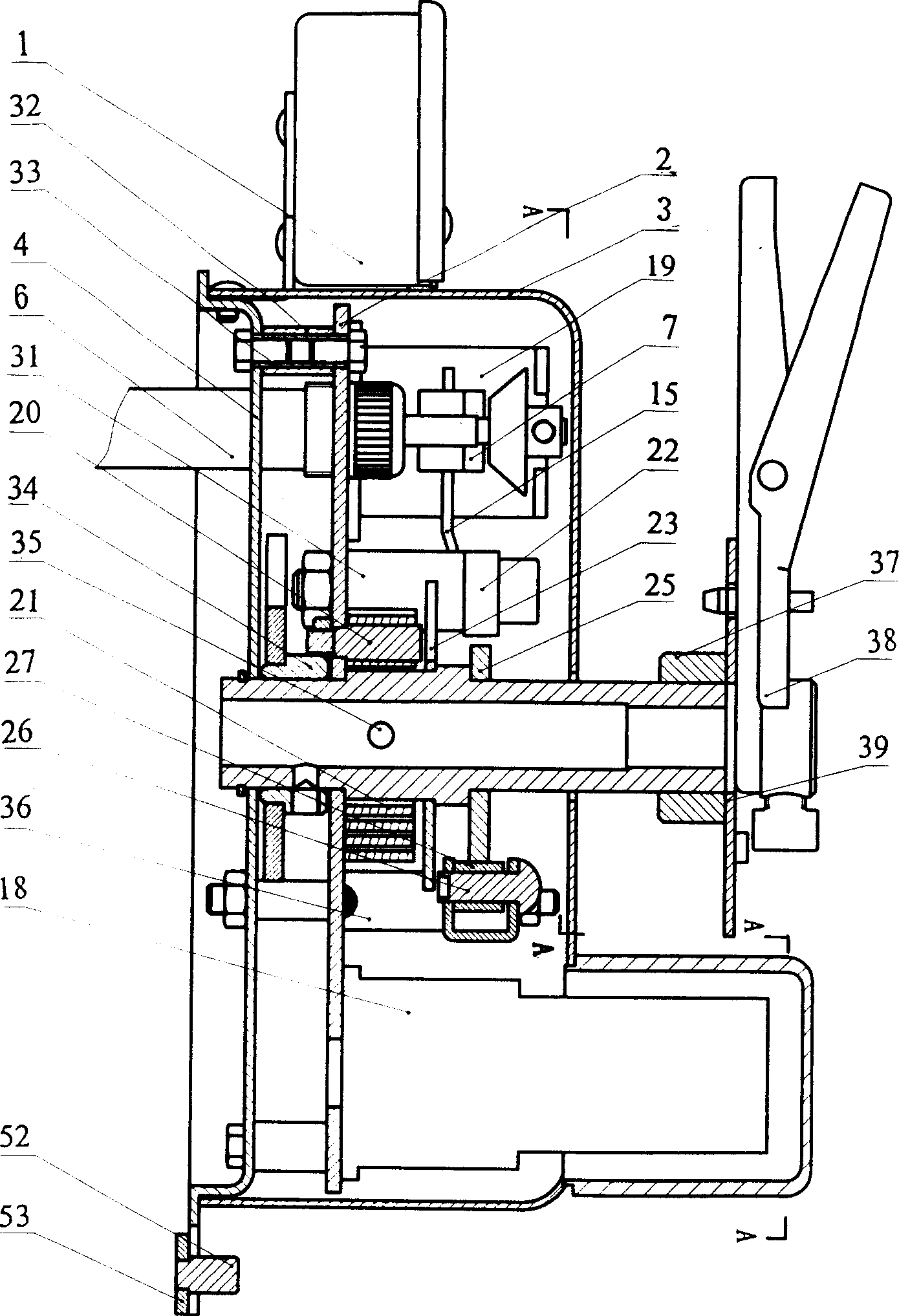

[0011] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0012] Flat square hole is arranged in the middle of cam 25, and the circular plate shape of arc-shaped gap is arranged on the edge.

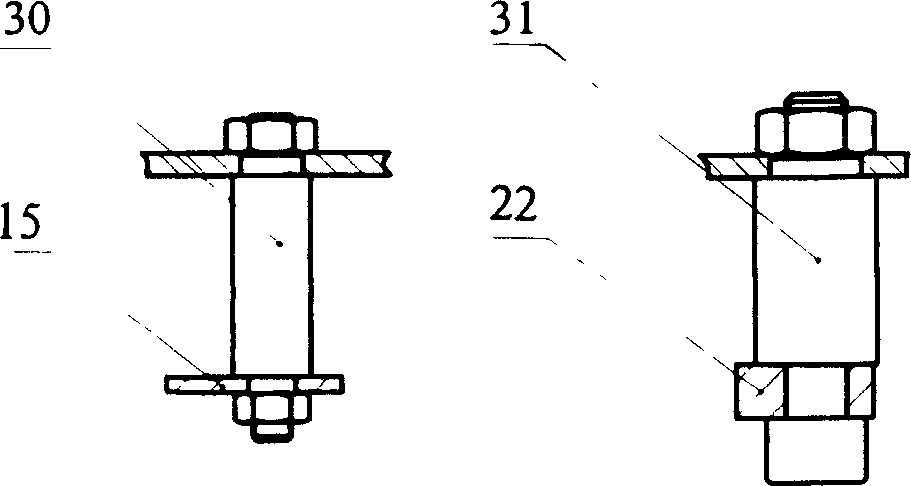

[0013] The main shaft 24 is in the shape of a stepped pipe, on which the fixed cam 25 and the fixed pressure ring 23 are welded, and the lower end passes through the mounting plate 2 and the bottom plate 4. The sector gear 50 is welded and fixed on the seat cover 34, and fixed on the main shaft 24 with stop screws. On the lower end, a collar is buckled in the ring groove at the end of the main shaft, and the main shaft 24 is connected to the lower surface of the base plate 2 .

[0014] The fixed shaft 20 is fixed on the mounting plate with a nut through the screw thread at the end, the outer end of the coil spring 21 is hooked on the fixed shaft 20, and fixed on the mounting plate 2 through the fixed shaft, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com