Whirlpool compressor

A scroll compressor and scroll technology, applied in the field of scroll compressors, can solve the problem that the compression ratio of the scroll compressor cannot be greatly improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The basic idea of "extended deformation correction" theory is as follows:

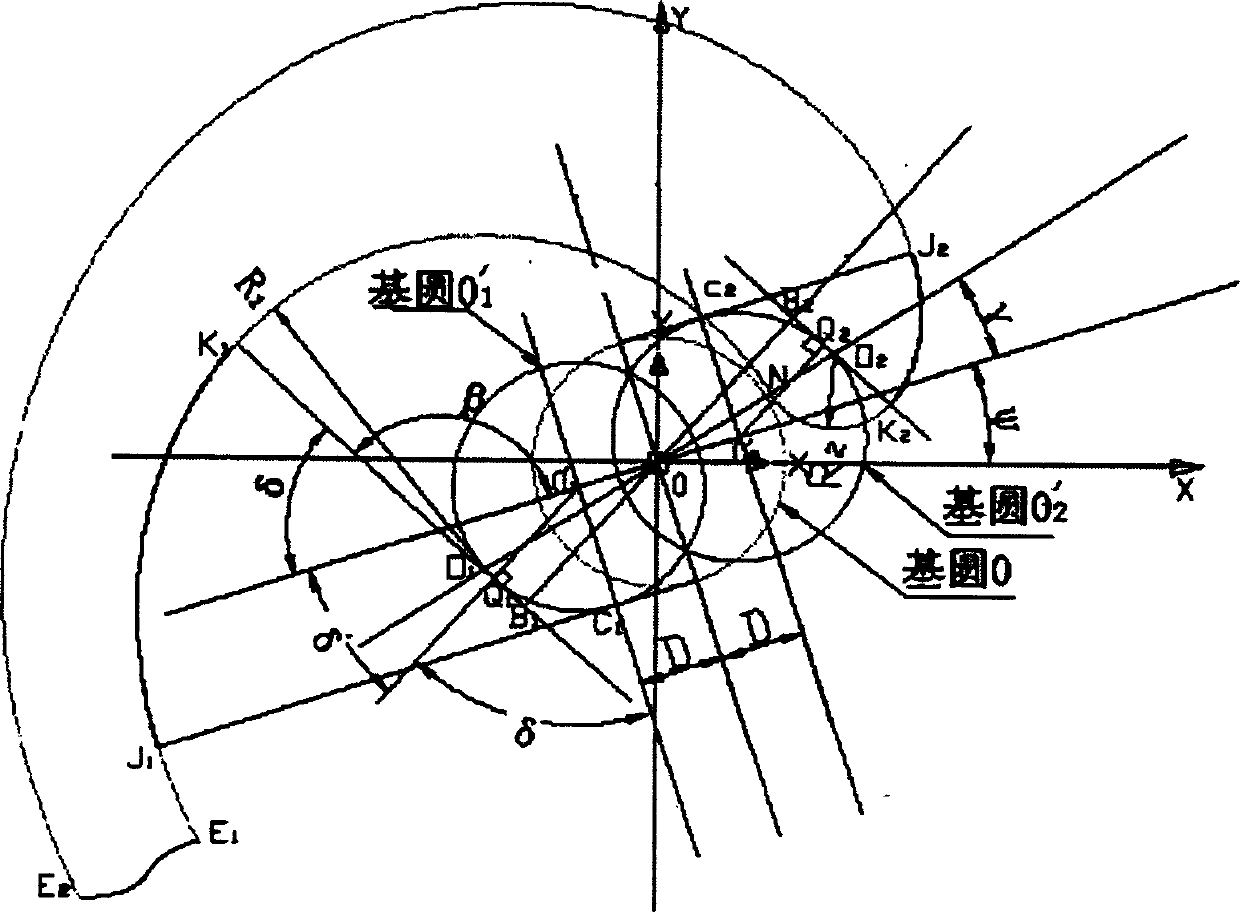

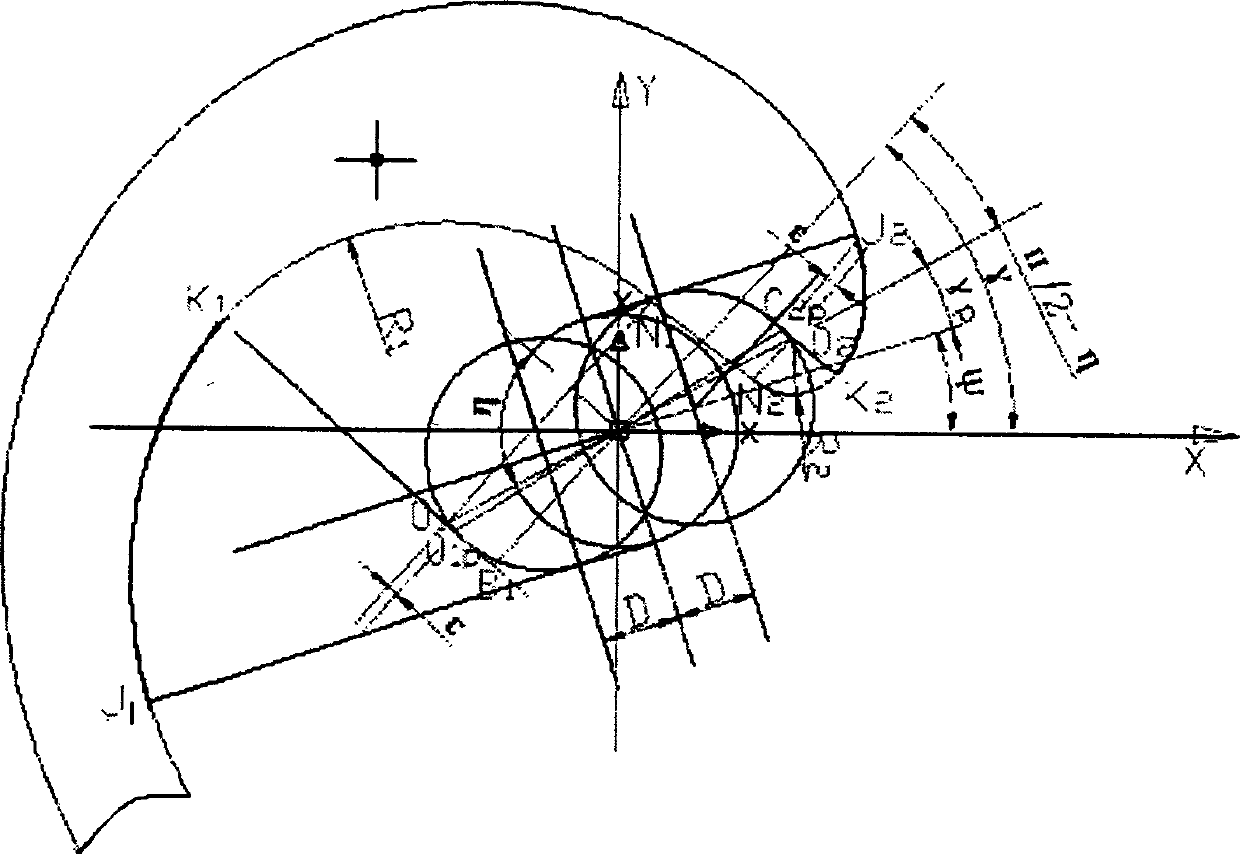

[0044] Such as figure 1 As shown, the main vortex base circle O, the center of which is at point O, now introduce two left and right slave base circles O′ with radius a and distance D from point O 1 and O' 2 , the centers of the three main and slave base circles are on a straight line, and the angle between the straight line where the three centers are located and the X axis is ψ. The inner and outer main vortex lines generated by the main base circle are involute J 1 E. 1 and J 2 E. 2, the starting angles are α and -α respectively, the radius of the main base circle is a, now set the starting point J of the inner and outer vortices 1 and J 2 does not change with the change of β angle, but in figure 1 fixed point in . right figure 1

[0045] J 1 The starting angle of the point is: α 1 = 3 π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com