Bisphenol type flame-retardant polycarbonate interface method preparation method

A flame-retardant polycarbonate and phenol-type technology, which is applied in the field of preparation of bisphenol-type flame-retardant polycarbonate, can solve the problems of high production risk, high production cost, difficult operation, etc. The effect of improved safety and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

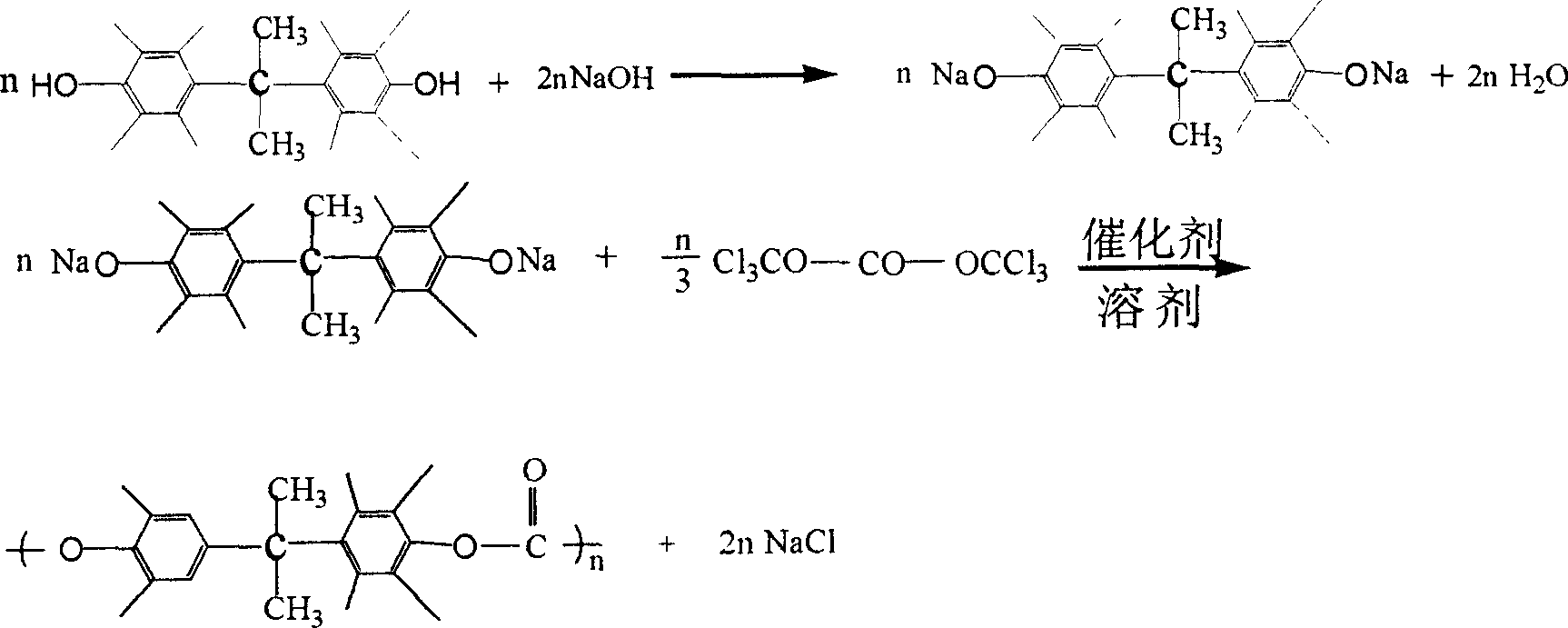

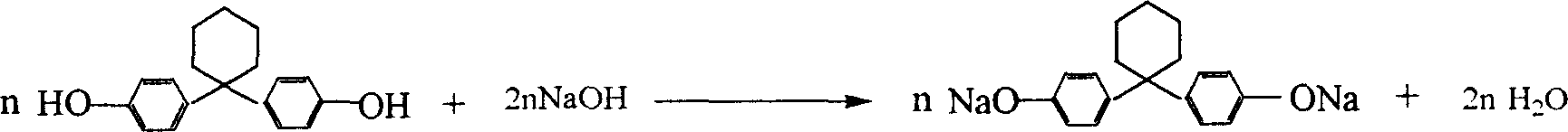

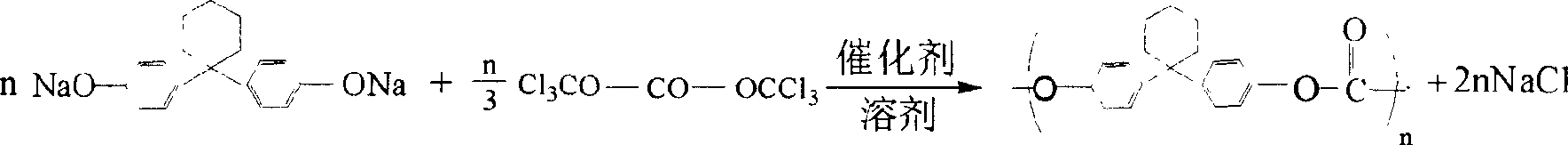

Method used

Image

Examples

example 1

[0026] (1) Prepare a three-neck flask.

[0027] (2) Add NaOH 0.543g in the flask to make a 2% aqueous solution;

[0028] (3) Add 3.4g 2,2-bis(3,5-dibromo-4-hydroxyphenyl) propane (tetrabromobisphenol A) to the flask and stir slowly until all dissolve to obtain tetrabromobisphenol A sodium Salt solution, its pH value is 13.45;

[0029] (4) Adjust the temperature to 10°C-15°C and add 10ml of CH to the flask 2 Cl2 , and then add catalyst N,N-dimethylethylamine 3.4ul;

[0030] (5) Weigh 0.68g triphosgene and dissolve in 15ml CH 2 Cl 2 stand-by;

[0031] (6) Control the temperature of the system in the flask at 10°C-15°C, slowly add triphosgene solution dropwise under strong stirring, and at the same time add dropwise 5% NaOH aqueous solution prepared in advance to keep the pH value of the reaction system in the range of 13-14 Inside;

[0032] (7) After the dropwise addition is completed, the temperature is rapidly raised to 24-26 ° C, and a sufficient stirring rate is maint...

example 2

[0035] (1) Prepare a three-neck flask.

[0036] (2) Add NaOH 0.53g in the flask to make a 2% aqueous solution;

[0037] (3) Add 3.4g 2,2-bis(3,5-dibromo-4-hydroxyphenyl) propane (tetrabromobisphenol A) in the flask, stir at a slow speed until all dissolve to obtain tetrabromobisphenol A Sodium salt solution, measuring its pH value is 13.35;

[0038] (4) Adjust the temperature to 10°C-15°C and add 10ml of CH to the flask 2 Cl 2 ;

[0039] (5) add 0.103g 2,4,6-tribromophenol in the flask;

[0040] (6) Add catalyst N,N-dimethylethylamine 3.4ul in the flask;

[0041] (7) Weigh 0.68g triphosgene and dissolve in 15ml CH 2 Cl 2 stand-by;

[0042] (8) Control the temperature of the system in the flask at 10°C-15°C, slowly add triphosgene solution dropwise under strong stirring, and at the same time add dropwise 5% NaOH aqueous solution prepared in advance to keep the pH value of the reaction system in the range of 13-14 Inside;

[0043] (9) After the dropwise addition is com...

example 3

[0046] (1) Prepare a three-neck flask.

[0047] (2) add NaOH 0.371g in the flask, be made into 2% aqueous solution;

[0048] (3) Add 2.38g 2,2-bis(3,5-dibromo-4-hydroxyphenyl) propane (tetrabromobisphenol A) in the flask, stir at a slow speed until all dissolve to obtain tetrabromobisphenol A Sodium salt solution, measuring its pH value is 13.64;

[0049] (4) Weigh 0.476g triphosgene and dissolve in 20ml CH 2 Cl 2 , added to the three-necked flask at one time;

[0050] (5) Adjust the temperature of the system in the flask to 10°C-15°C and add 2.4ul of catalyst N,N-dimethylethylamine at one time, and stir for 5 minutes;

[0051] (6) Rapidly heat up to 24°C-26°C for reaction, and simultaneously add dropwise 5% NaOH aqueous solution prepared in advance to keep the pH value of the reaction system in the range of 13-14, and react for 1 hour.

[0052] (7) Wash with 21ml of 3% hydrochloric acid after completion of the reaction, wash twice with water, evaporate to dryness in vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com