Double distillation type multiple-effect distilled water machine

A technology of distilled water machine and double distillation, which is used in multi-effect evaporation, tubular still, heating water/sewage treatment, etc. It can solve the problems of reduced evaporation energy of evaporator, reduced evaporation energy, complicated equipment structure, etc., and achieve the effect of evaporation. The effect of improving, high utilization rate of heat energy, and sufficient evaporation and vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

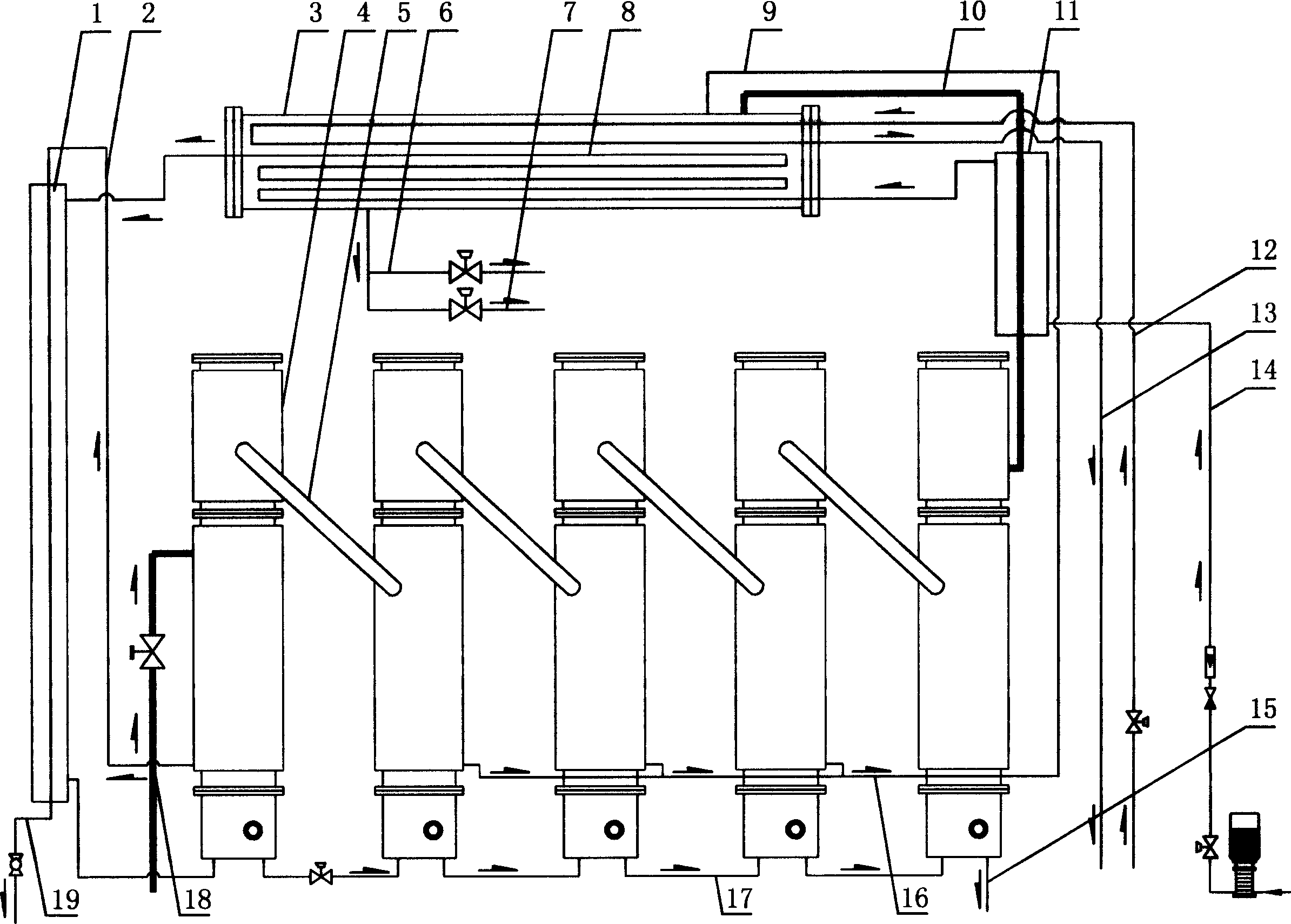

[0019] The present invention as figure 1 Alternate installation shown.

[0020] Before use, the steam inlet pipe 18 is connected with the steam source, the raw material water pipe 15 is connected with the water source through a pump and a valve, and an electrical control device is installed in a conventional manner.

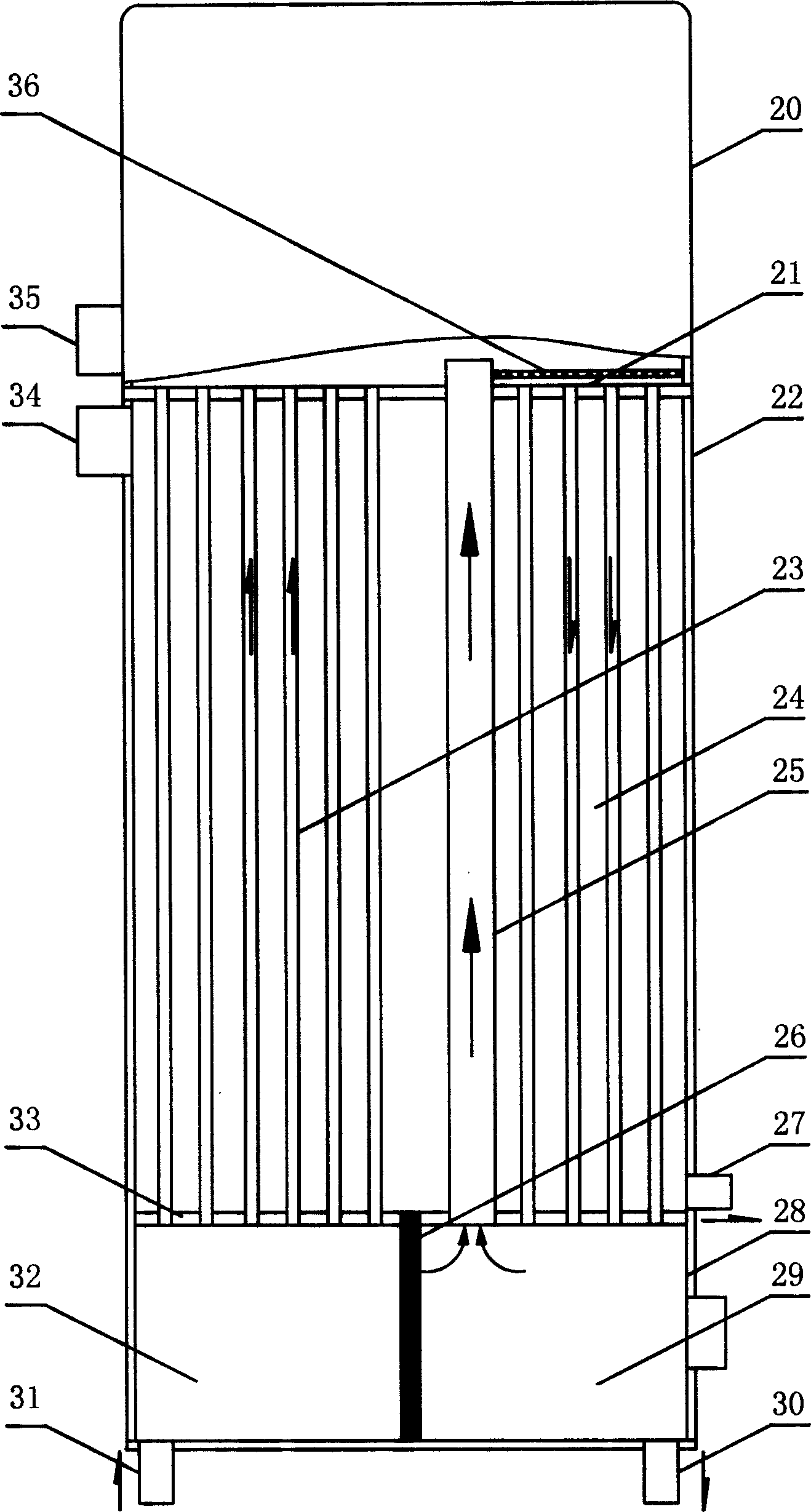

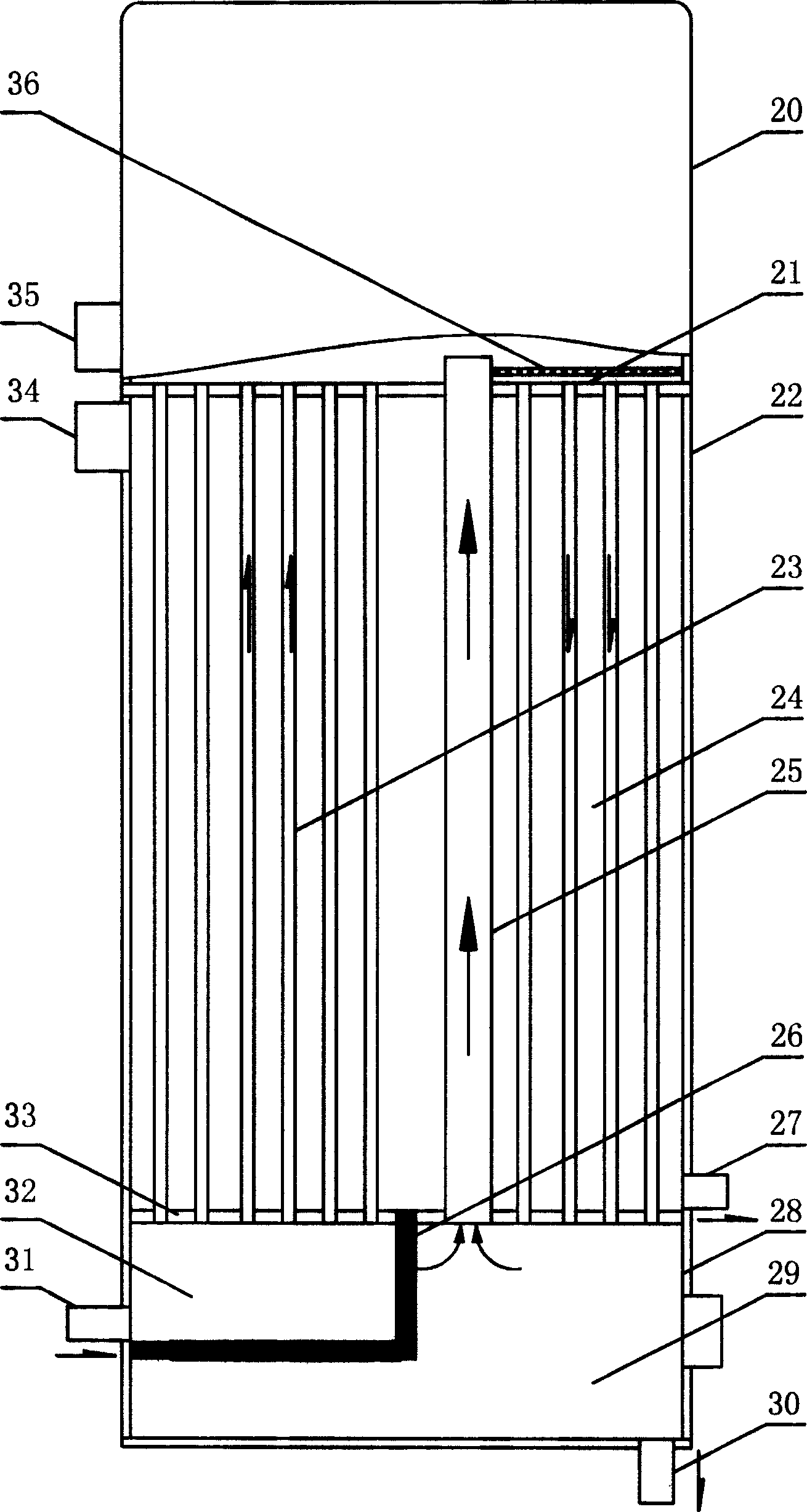

[0021] When in use, through the steam inlet pipe 18 and the steam inlet 34 of the evaporation section 22 connected with it, the high-temperature industrial boiler steam is injected into the evaporation chamber 24 of the evaporation section 22 of the first effect evaporator 4, and the high-temperature steam quickly Heat up the tubes 23 in the evaporation section 22, and at the same time, the raw water enters the water chamber through the water inlet 31 of the rising film water chamber 32, and quickly fills the rising film water chamber 32, because the water rises at the same level , so it rises quickly and evenly along each row of tubes 23, and is heated by high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com