LCD unit and thin type backlight module thereof

A technology of liquid crystal display unit and backlight module, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of unstable optical properties of backlight modules, difficulty in automatic/semi-automatic assembly, and streak-like phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

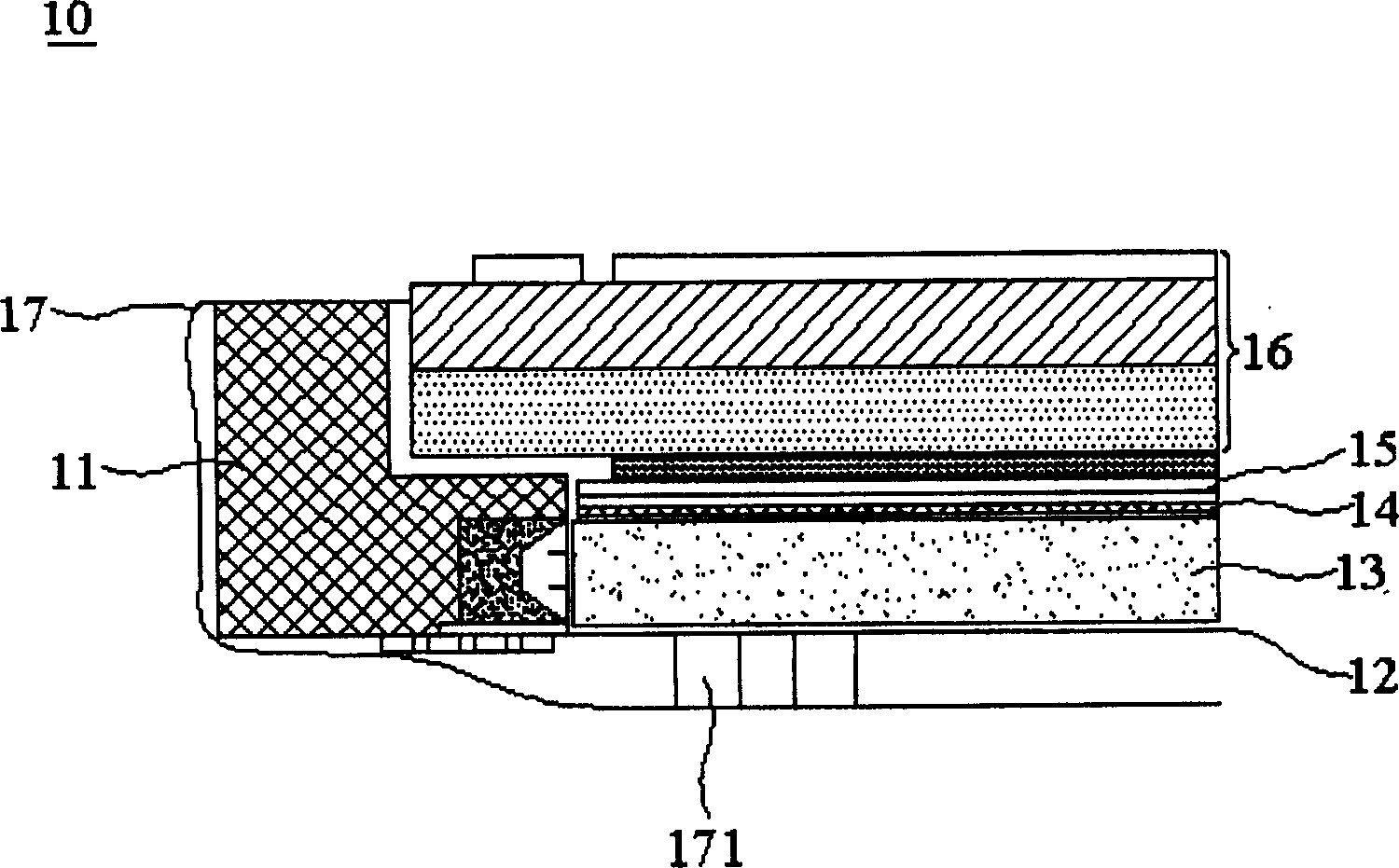

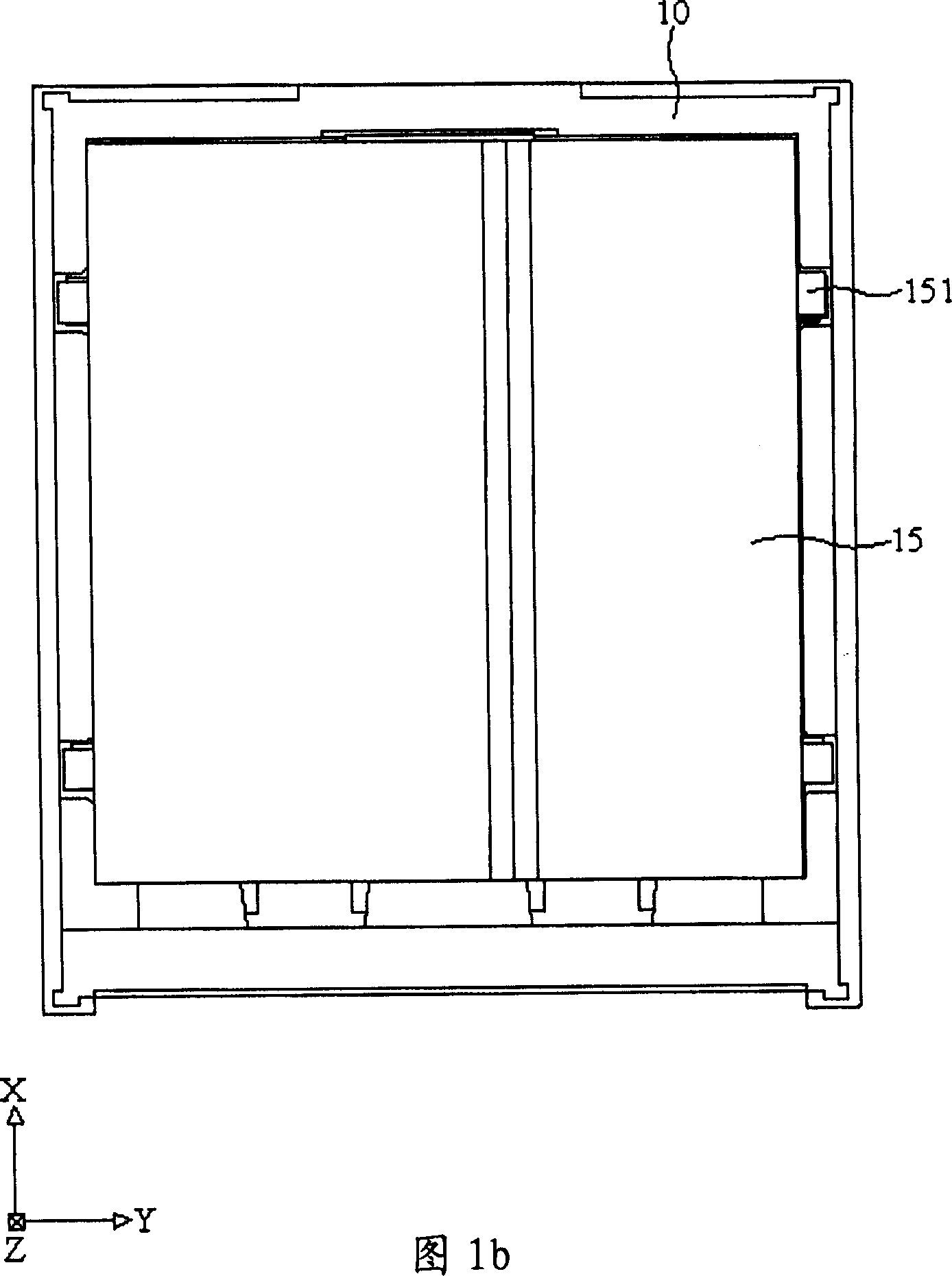

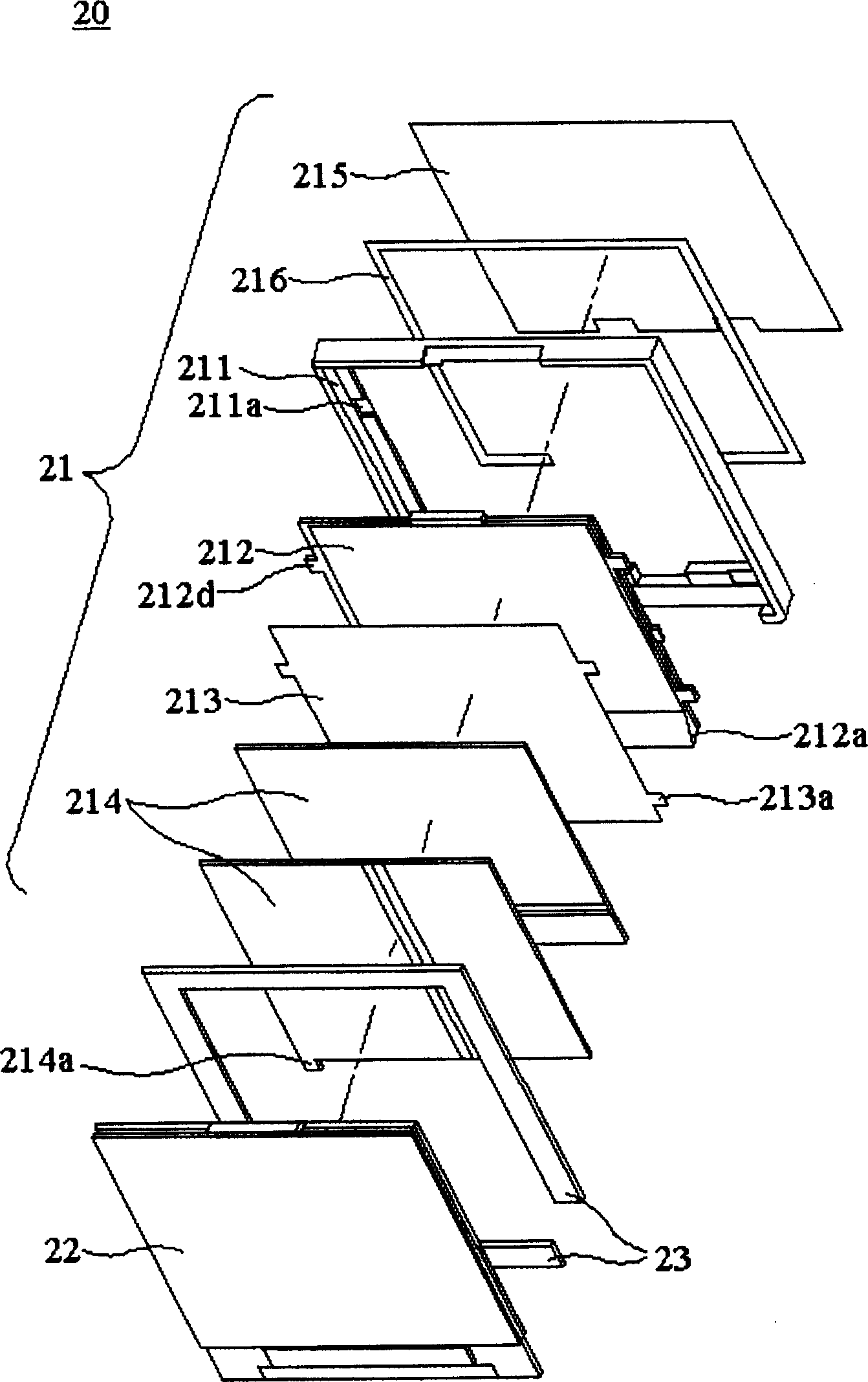

[0075] Figures 2a, 2b, and 2c show the first embodiment of the liquid crystal display unit of the present invention. In this embodiment, the liquid crystal display unit 20 includes a backlight module 21 and a liquid crystal panel 22, wherein the liquid crystal panel 22 is arranged on the backlight The backlight module 21 includes a frame 211 , a light guide plate 212 , a diffusion sheet 213 , two prism sheets 214 and a reflective sheet 215 .

[0076] The frame 211 can be used for disposing the liquid crystal panel 22 therein, and is preferably made of plastic; in addition, the frame 211 has several grooves 211a formed around its inner side for clamping the light guide plate 212 or the diffusion sheet 213 .

[0077] The light guide plate 212 is arranged in the frame 211, and as shown in Figures 3a, 3b, and 3c, a first protruding portion 212a is formed thereon, and a notch 212b is formed by forming the first protruding portion 212a, the notch 212b can be used to improve the optica...

no. 2 example

[0090] Figures 4a and 4b show the second embodiment of the liquid crystal display unit of the present invention. In this embodiment, the liquid crystal display unit 20' includes a backlight module 21', a liquid crystal panel 22 and a flexible circuit board 24'; Note that in this embodiment, the same components as those of the first embodiment are assigned the same symbols, and descriptions thereof are omitted.

[0091] The difference between this embodiment and the first embodiment is that the frame 211' of the backlight module 21' forms a stepped portion 211b on its outer side (that is, the side not adjacent to the light guide plate 212), thereby connecting with the liquid crystal panel 21. In the flexible circuit board 24 , some of the electronic components 241 with a relatively high height can be located in the stepped portion 211 b, so as to reduce the overall thickness of the liquid crystal display unit 20 ′.

[0092] In addition, the liquid crystal display unit 20' can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com