Substrate bearing apparatus

A carrier device and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as loose inspection and maintenance, cassettes that cannot be stacked, panels that are easy to scratch lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical content of the present invention, the following preferred specific embodiments are specially cited as follows.

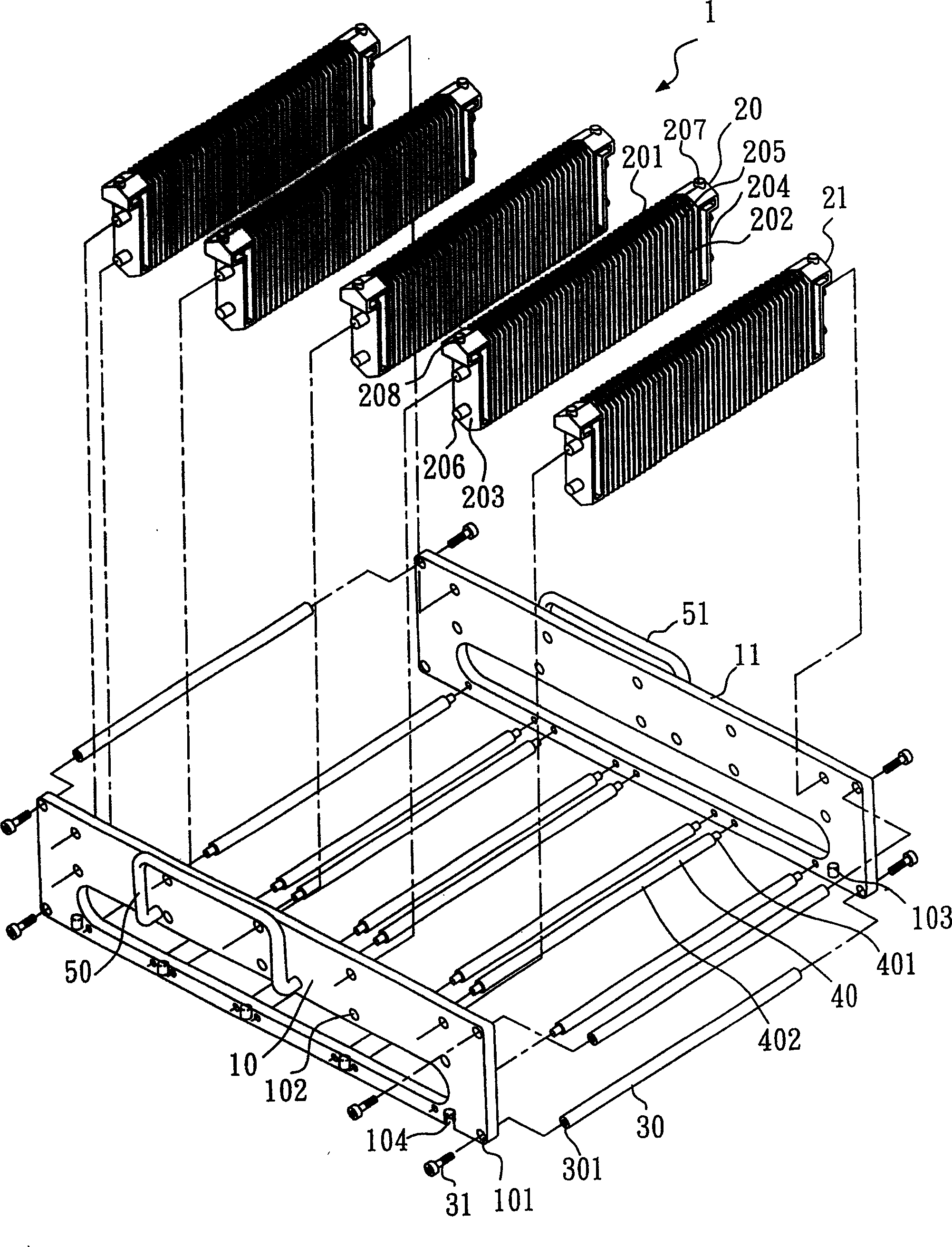

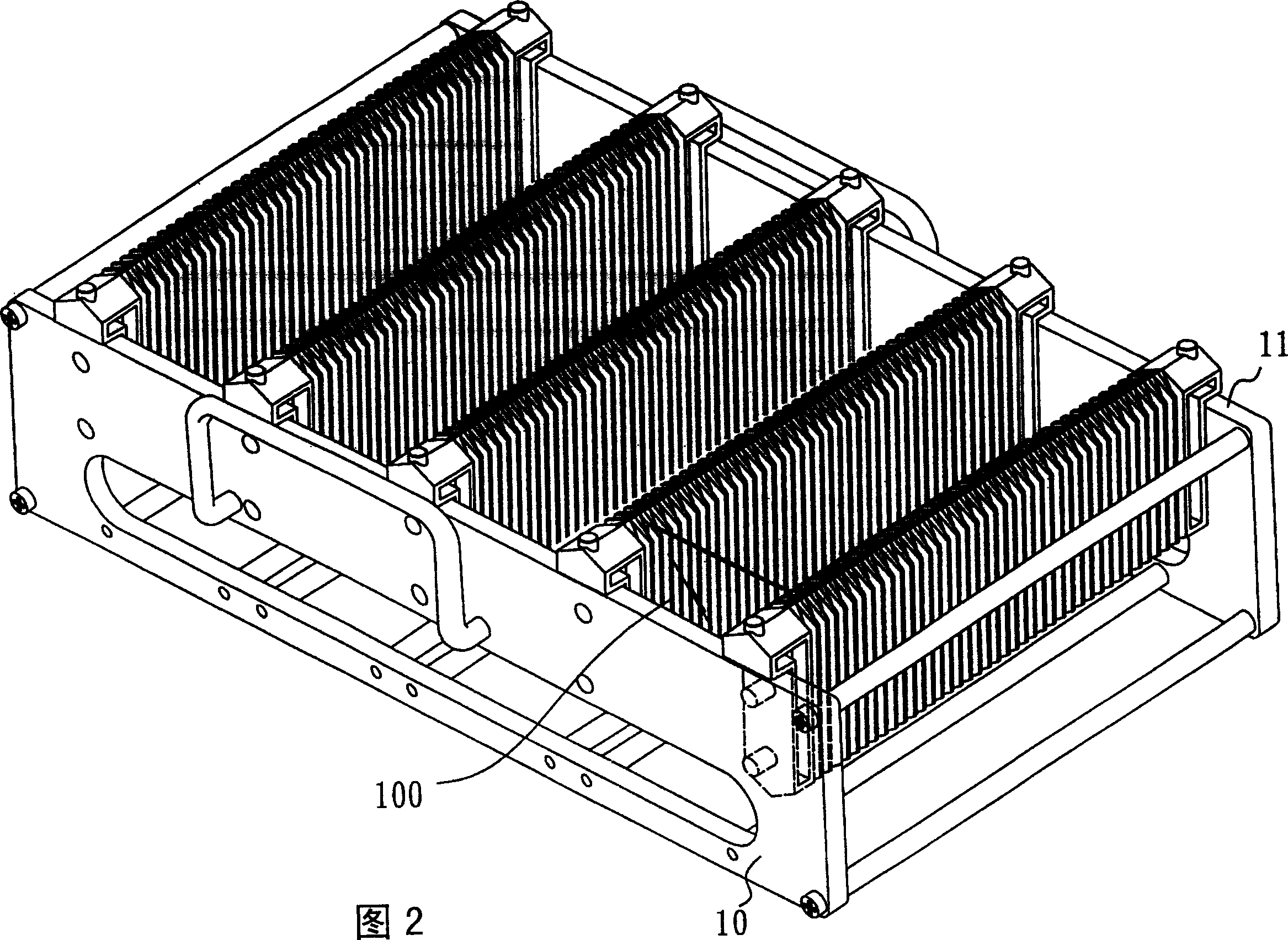

[0021] See figure 1 , figure 1 It is a perspective view of the substrate carrying device of the present invention before assembly, the substrate carrying device 1 includes side plates 10, 11, and a plurality of fixing holes 101 and positioning holes 102 horizontally penetrating into the side plates 10, 11 are formed on the side plates 10, 11, and A plurality of positioning holes 103, 104 vertically penetrate the side plates 10, 11 from below, and the fixing holes 101 are located near the corners of the side plates 10, 11; a plurality of partitions 20, the partitions 20 have two sides 201, 202 , and two sides 203,204, a plurality of parallel grooves 205 are formed on the side surfaces 201,202 for inserting the substrate, and there are two positioning pins 206 respectively on the side sides 203,204, by positioning th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com