Azo type disperse dyes in use for coloration in acid-alkalinity bath

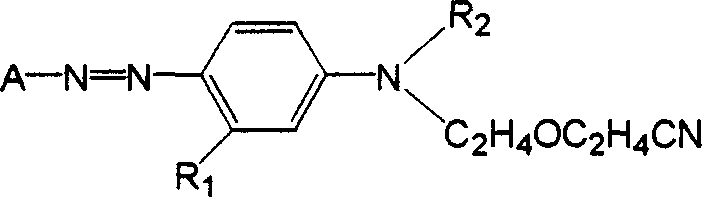

A disperse dye and azo technology, applied in the direction of azo dyes, preparation of azo dyes, organic dyes, etc., can solve the problems of low dyeing rate, poor dyeing performance, slow dyeing speed, etc., and achieve dyeing rate High, excellent dyeing performance, fast dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

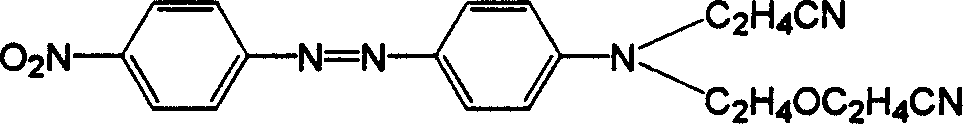

Examples

Embodiment 1

[0030] Control below 20°C, slowly add 7.25g (100%) sodium nitrite (0.105mol) to 80ml 93% sulfuric acid, then raise the temperature to 60-70°C and keep it for 1 hour, then cool down to 0°C Next, slowly add 19.5 grams (100%) of 3-amino-5-nitro-2,1-benzoisothiazole (0.1 mole), the temperature is lower than 5°C when adding, and keep below 5°C for 3 hours, Obtain diazo solution. At the same time, 23.2 g (100%) of N-ethyl-N (β-cyanoethoxyethyl) m-toluidine (0.1 mol) was dissolved in 10 ml of 93% sulfuric acid and 300 ml of ice water, and crushed Cool the ice to below 0°C and prepare the coupling components. Then slowly drop the diazo solution into the coupling component, control the temperature not to exceed 5°C, react at 0-5°C until the diazo component disappears, filter, wash with water until neutral, exhaust, and dry to obtain 37.9 grams of dye , and the yield was 86.5%.

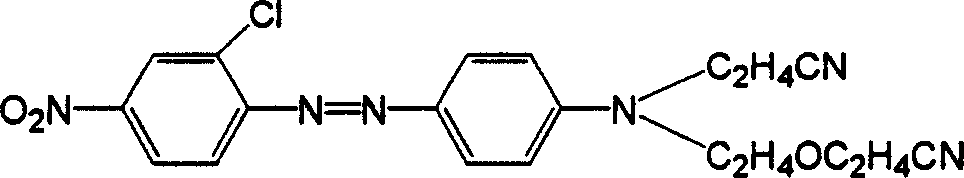

Embodiment 2-3

[0032] In each embodiment, the consumption of 3-amino-5-nitro-2,1-benzoisothiazole is 0.1 mole, and other materials (wherein coupling component R 1 , R 2 As shown in table 1) proportioning (mol ratio) and operation method are with embodiment 1, and its result is:

Embodiment 2

[0033] Embodiment 2: get dyestuff 35.7 grams, yield rate is 84.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com