Microwave coprecipitation method for preparing nano glaze of lead metaborate

A lead metaborate and co-precipitation technology is applied in the field of preparation of nano borate, which can solve the problem that nano lead metaborate powder has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

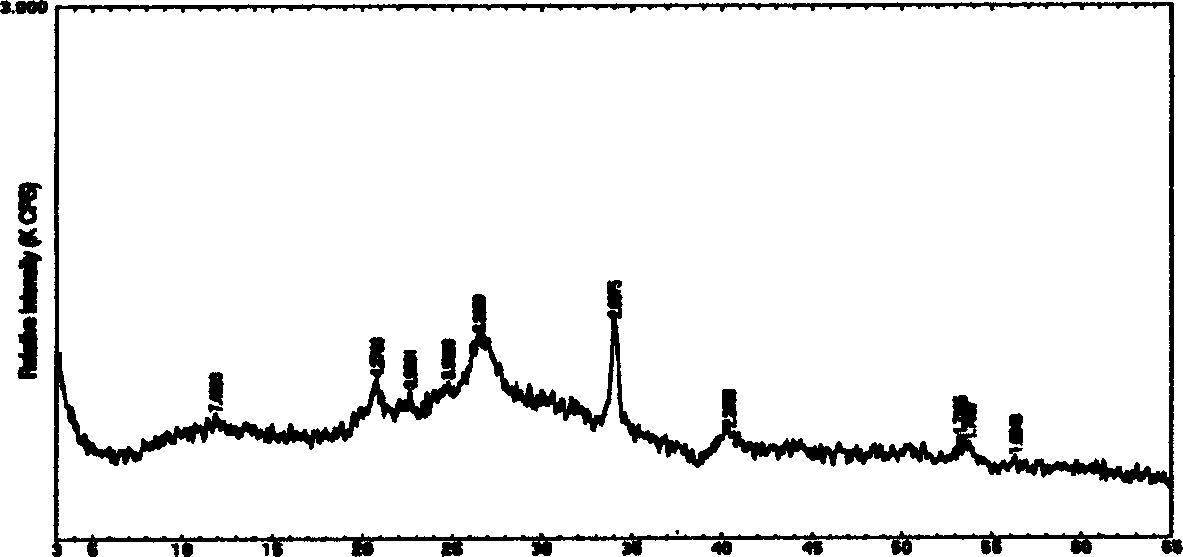

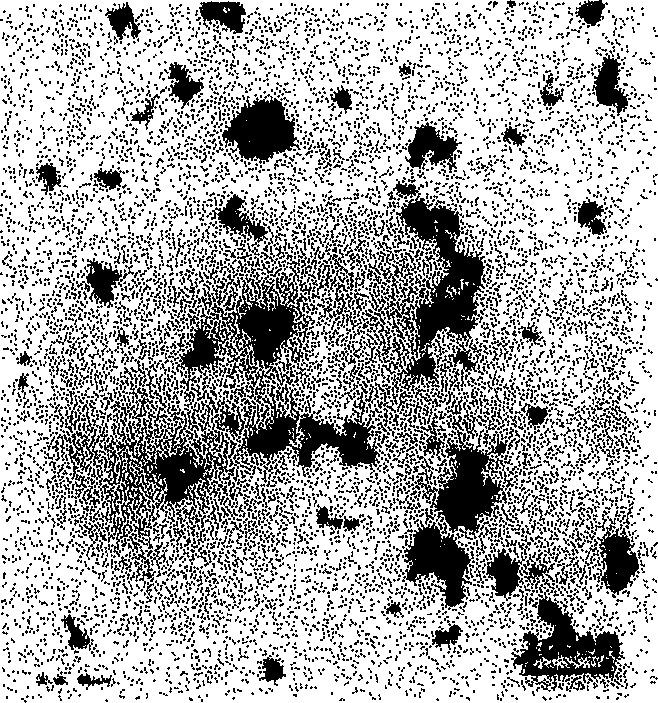

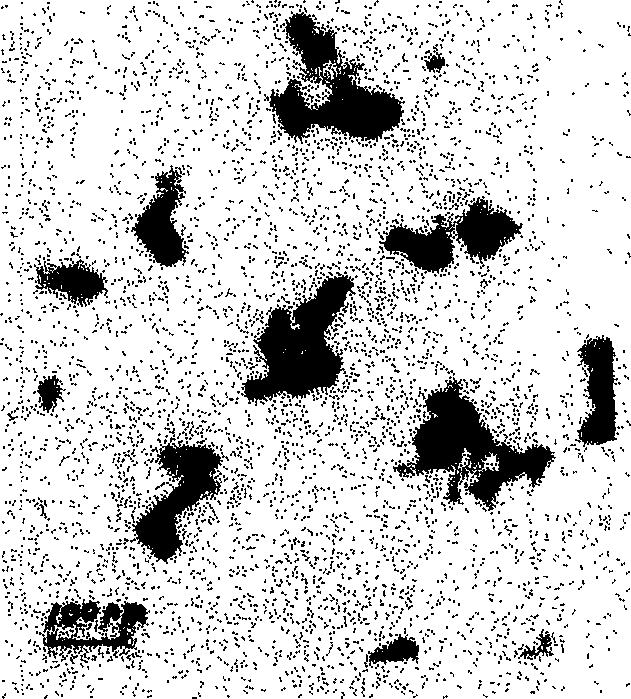

Image

Examples

Embodiment Construction

[0024] The microwave co-precipitation preparation method of nano-metaborate glaze is realized by the following steps:

[0025] (1) taking by weighing mol ratio is that sodium borate and lead nitrate of 1: 1 are mixed with 20% sodium borate aqueous solution and 20% lead nitrate aqueous solution respectively;

[0026] (2) Weigh 2-ethylhexyl sodium sulfosuccinate (AOT) and add it to the above prepared lead nitrate aqueous solution so that the concentration of 2-ethylhexyl sodium sulfosuccinate is 2%, and fully stir;

[0027] (3) Slowly inject the above-mentioned sodium borate aqueous solution into the mixed solution of 2-ethylhexyl sodium sulfosuccinate and lead nitrate aqueous solution, and fully stir to produce precipitation, keep the temperature at 35-45 degrees, and react for 1.5-2h; then 500w Microwave irradiation intermittent treatment for 4-6 minutes, so that the solution temperature is 80-100 degrees;

[0028] (4) the above-mentioned product is centrifuged to separate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com