Method for cyclic utilizing mineral dressing waste water from sulphur ore of lead-zinc

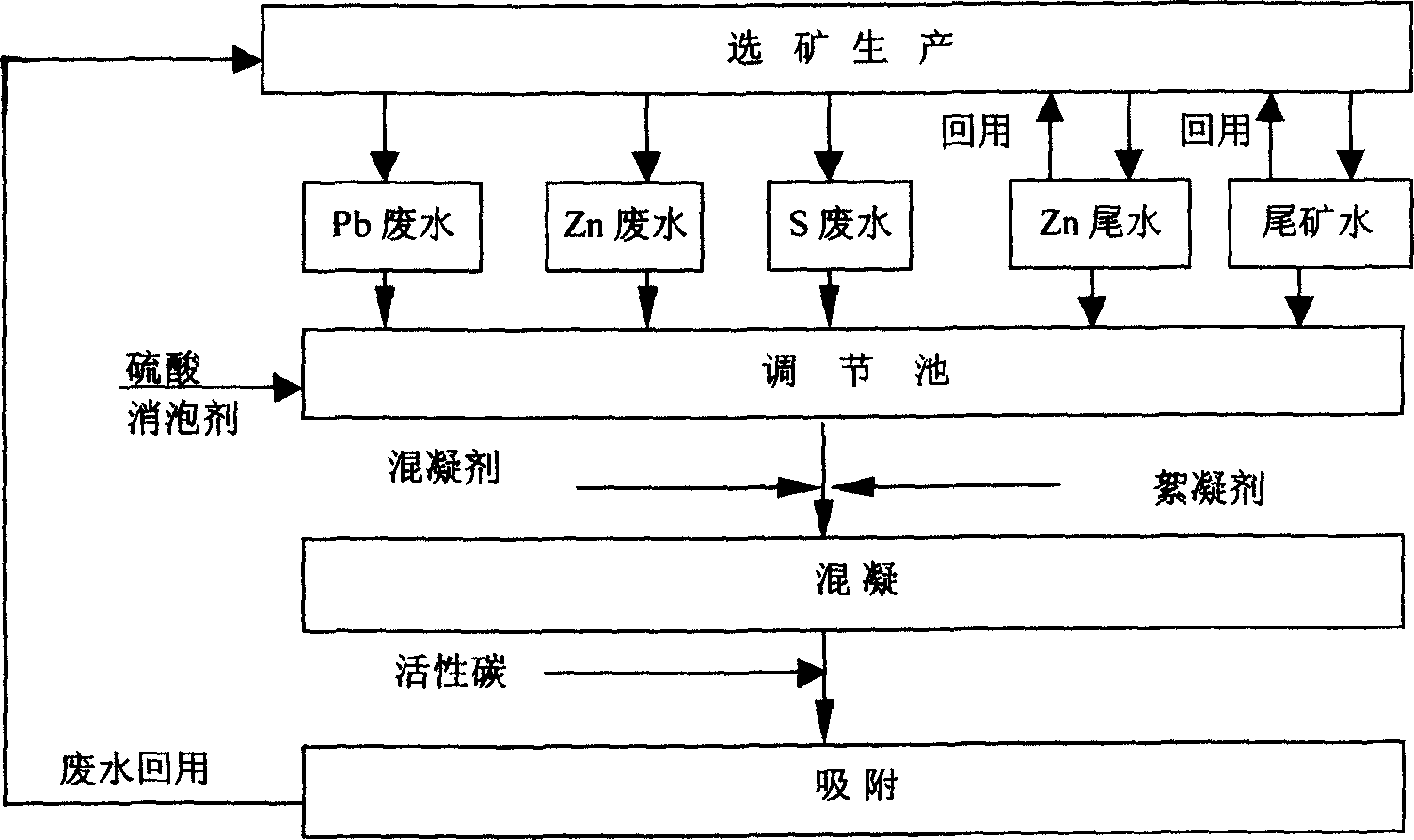

A technology for beneficiation wastewater and sulfide ore, which is applied in adsorption water/sewage treatment, neutralized water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of low utilization rate of chemical components, environmental pollution and high treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add a certain concentration of aluminum sulfate to the mineral processing wastewater, mix well, let it stand for 30 minutes, and then take a sample for analysis. The treatment results are shown in Table 1. When the amount of aluminum sulfate is 20-40mg / L, part of the heavy metal ion concentration and turbidity of the mixed wastewater reach a lower level. The water quality is also relatively clear.

[0014] Dosage of Aluminum Sulfate

Embodiment 2

[0016] Add a certain concentration of aluminum sulfate and flocculant to the mineral processing wastewater, mix well, let stand for 30 minutes, and then take samples for analysis. See Table 2 for the treatment results. It can be seen from Table 2 that when the aluminum sulfate is 40mg / L, the flocculant in the range of 0.2-0.5mg / L has a better treatment effect.

[0017] Aluminum sulfate=20mg / L, Ph=11.30

Embodiment 3

[0019] Add a certain amount of aluminum sulfate and flocculant to the waste water, mix well, and let it stand for 30 minutes, then add different amounts of powdered activated carbon, mix evenly, stand still and take samples for analysis. The amount of powdered activated carbon added and the results are shown in Table 3. The COD in the mixed wastewater decreases with the increase of powdered activated carbon, and the foaming performance decreases. Therefore, when the foaming agent and other organic refractory agents in the mixed wastewater accumulate to a certain extent, it is an effective way to use activated carbon to improve the quality of the wastewater and reduce the impact on the flotation index.

[0020] Powdered activated carbon (mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com