Inerting protection method and protection device in use for silo of storing raw coal

A protection device, raw coal technology, applied in fire rescue and other directions, can solve problems such as inability to monitor in time, unrealistic fire fighting, difficult control, etc., and achieve the effects of direct inerting protection, flexible protection methods, and optimal protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

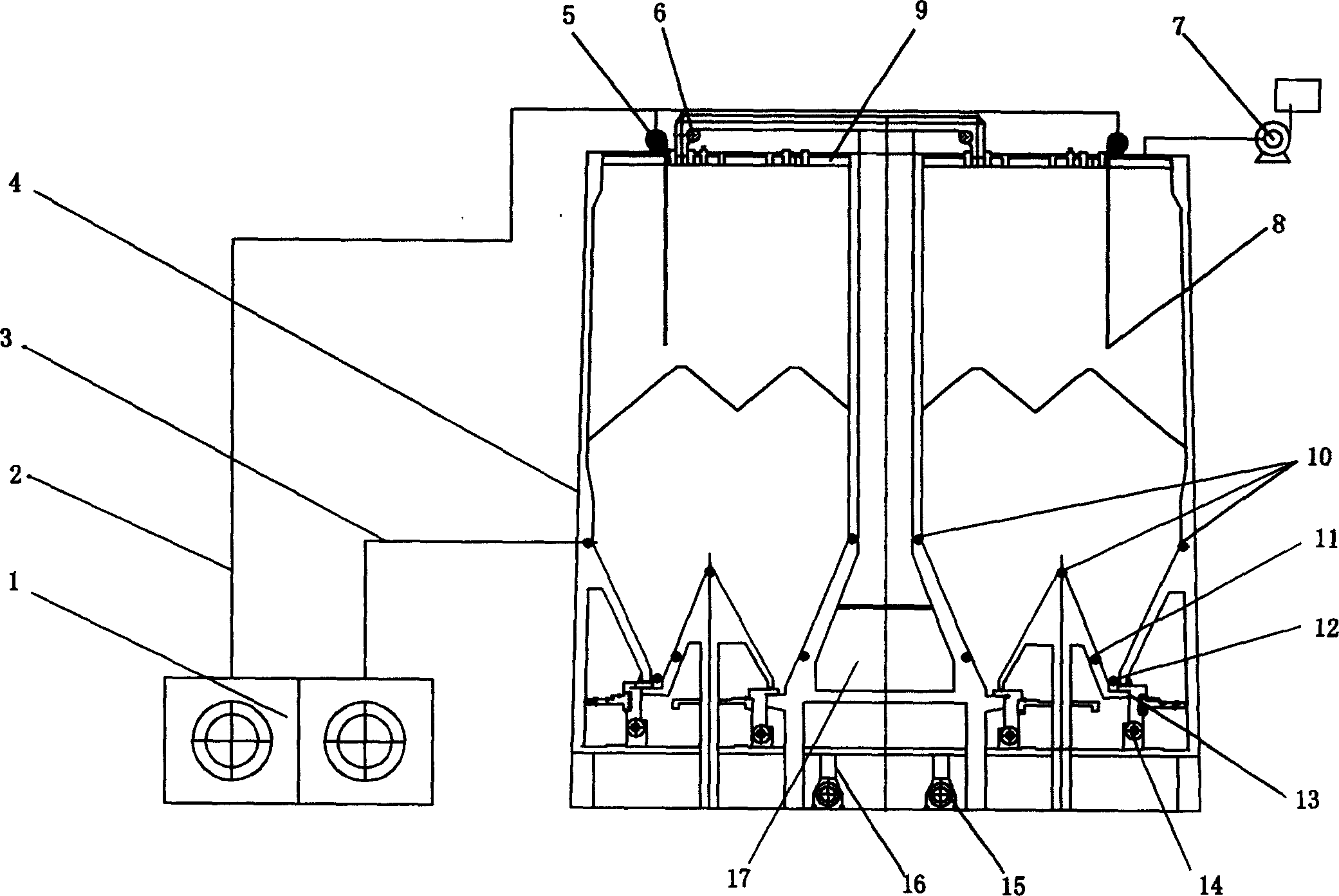

[0041] This embodiment is a specific application example of the raw coal silo inerting protection device on a large raw coal silo above 30,000 tons.

[0042] The structure of a large raw coal silo above 30,000 tons is as follows: figure 1 As shown, its main structure is a circular silo made of reinforced concrete, a hollow support column 17 is arranged in the center of the silo, and the interior of the silo is a ring structure. The upper part of the silo is a flat-top silo roof 9, on which there is a ring-type coal distributor 6 to add coal to the silo, and a dust collector 7 is used to remove the dust raised on the surface of the coal seam when adding coal. The lower part of the silo is closed in a conical shape, and a ring-shaped umbrella-shaped cone bottom is set at the bottom. Two ring-type coal unloaders 13 and ring-type coal conveyors 14 are set at the bottom of the inner and outer cones of the ring for unloading coal from the silo. Coal, the unloaded pulverized coal fa...

Embodiment 2

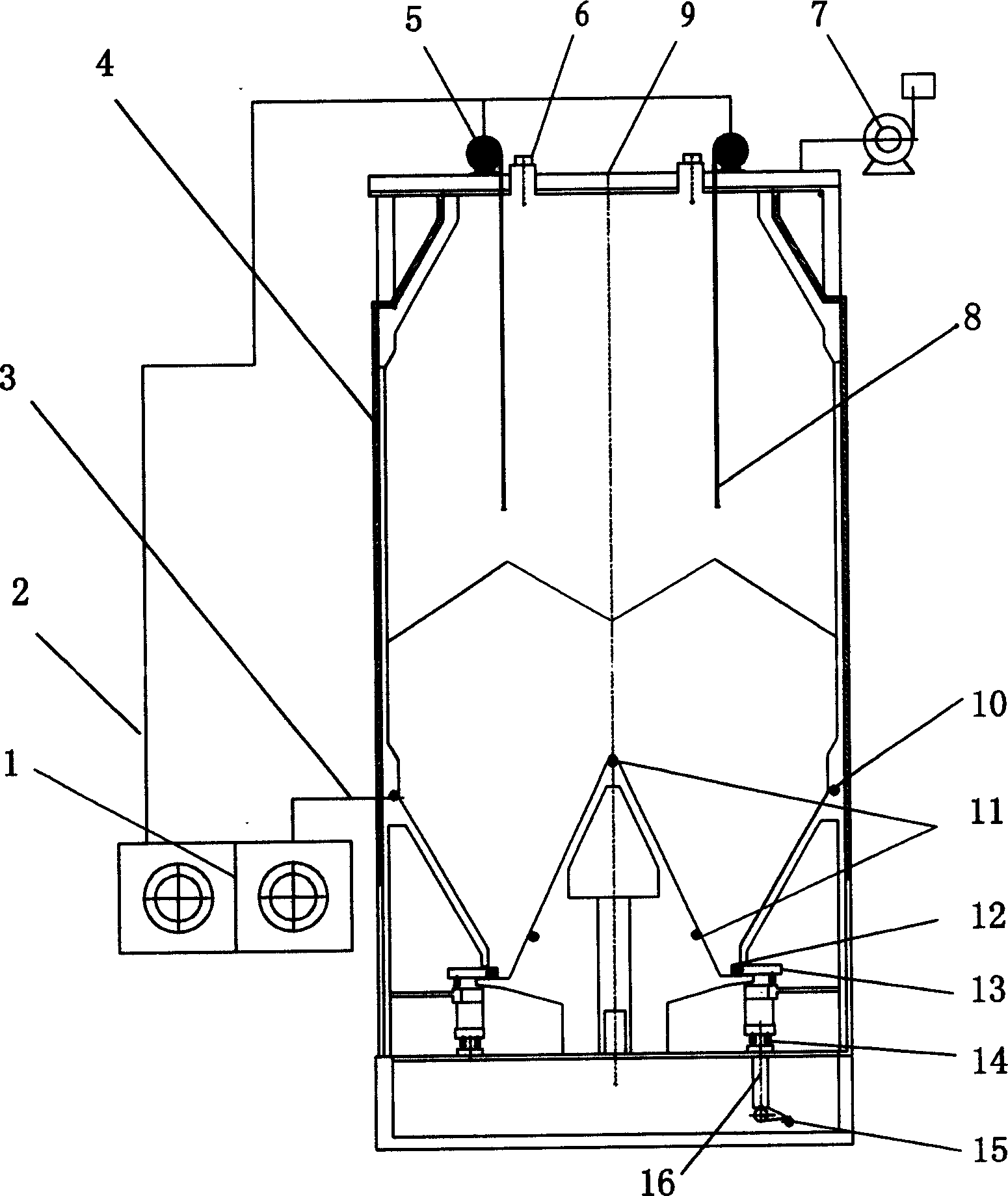

[0062] This embodiment is a specific application example of the raw coal silo inerting protection device on a medium-sized raw coal silo below 10,000 tons.

[0063] The structure of medium-sized raw coal silos below 10,000 tons is as follows: figure 2 As shown, its main structure is a circular silo made of reinforced concrete; the upper part of the silo is a flat top silo roof 9, on which a ring-type coal distribution machine 6 is provided to add coal to the silo, and a dust collector 7 is used to The dust raised on the surface of the coal seam is removed when coal is added; the lower part of the silo is conical closed, and an umbrella-shaped conical bottom is set at the bottom, and a ring-type coal unloader 13 and a ring-type coal conveyor 14 are set at the bottom of the cone for Coal is unloaded in the silo, and the unloaded coal powder falls in the coal drop pipe 16 below, and is carried away by the coal conveying belt 15.

[0064]Several telescopic inflation devices 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com