Sealed tank gas-discharging lid

A technology for venting caps and sealed cans, which is applied in the directions of sealing, closing, and packaging, and can solve problems such as inability to discharge, affecting the storage requirements of internal contents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

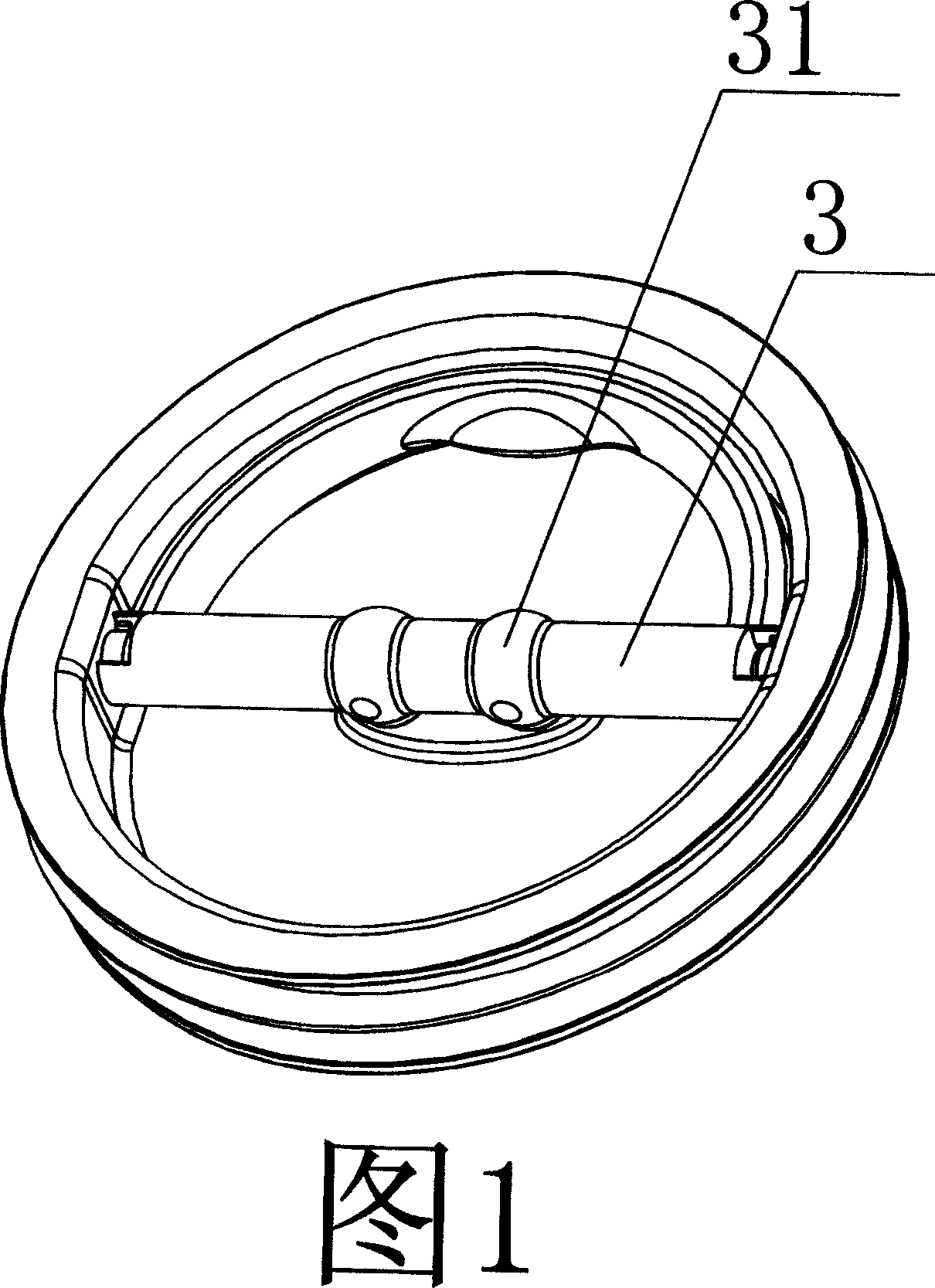

[0024] The following is a detailed description in conjunction with Figure 1 and Figure 2:

[0025] A vent cover for a sealed tank, which is composed of a cover body 1, and a sealing ring is fixed on the peripheral part of the cover body, which is convenient for sealing and snapping into the inner peripheral part of the tank body. It is characterized in that the cover body is provided with at least one vent hole 11 in the radial direction , the upper part of the vent hole is provided with a concentric circular groove 111, and the concentric circular groove is provided with a gas-blocking silicon rubber ring (2). The rotating shaft is fixed with a convex ring part 31, which is convenient for pressing the gas-blocking silicone rubber ring. The convex ring part is provided with a vent hole 32 in the radial direction. When the rotating shaft turns to the vent hole and the vent hole, the vent hole When the exhaust cover is snapped into the tank body, the remaining air in the tank ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com