Integrated manual multiple directional control valve for lader

A multi-way reversing valve, integrated technology, applied in lifting devices, mechanical equipment, fluid pressure actuating devices, etc., can solve problems such as safety accidents, high internal leakage, and difficult processing of hollow valve stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

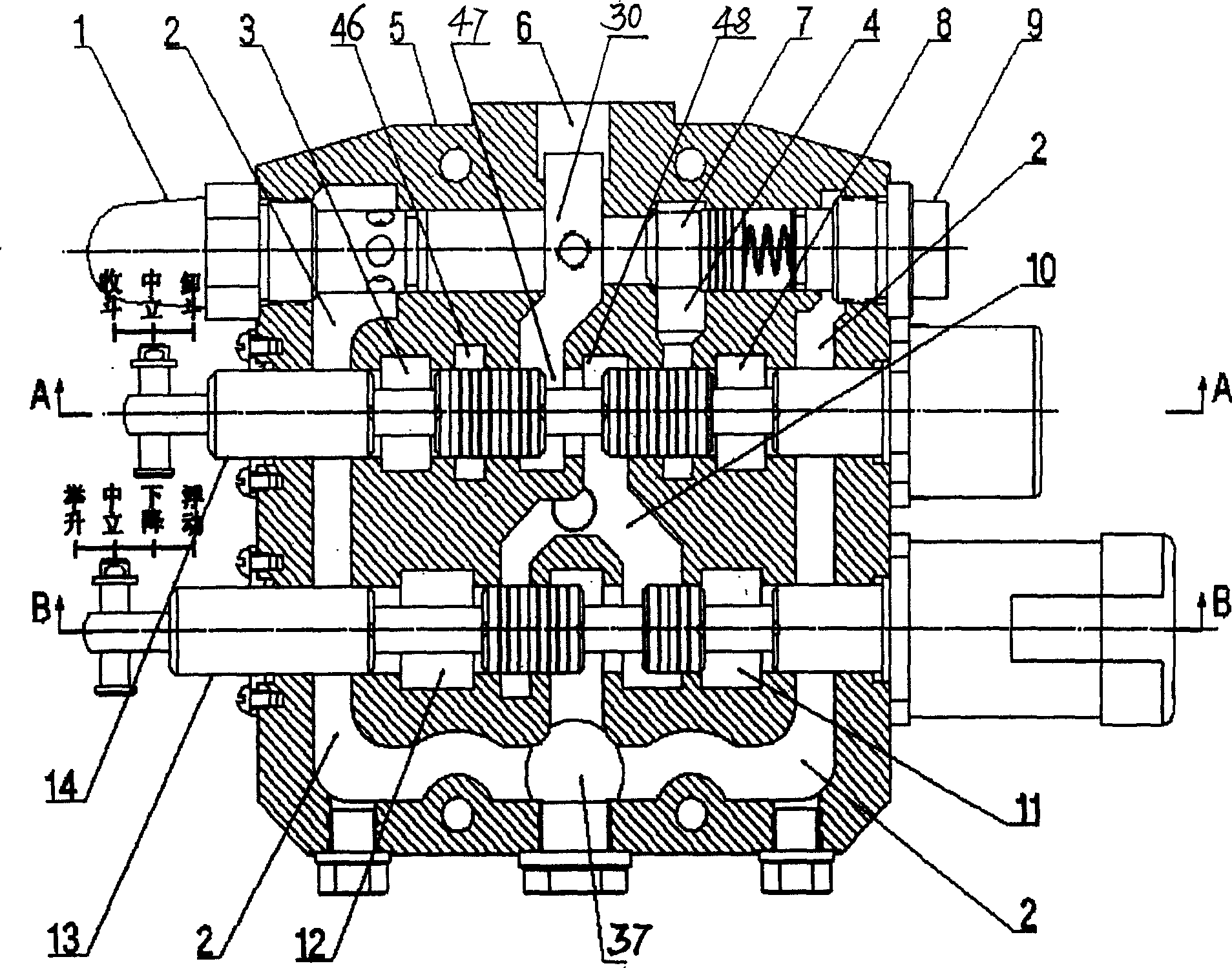

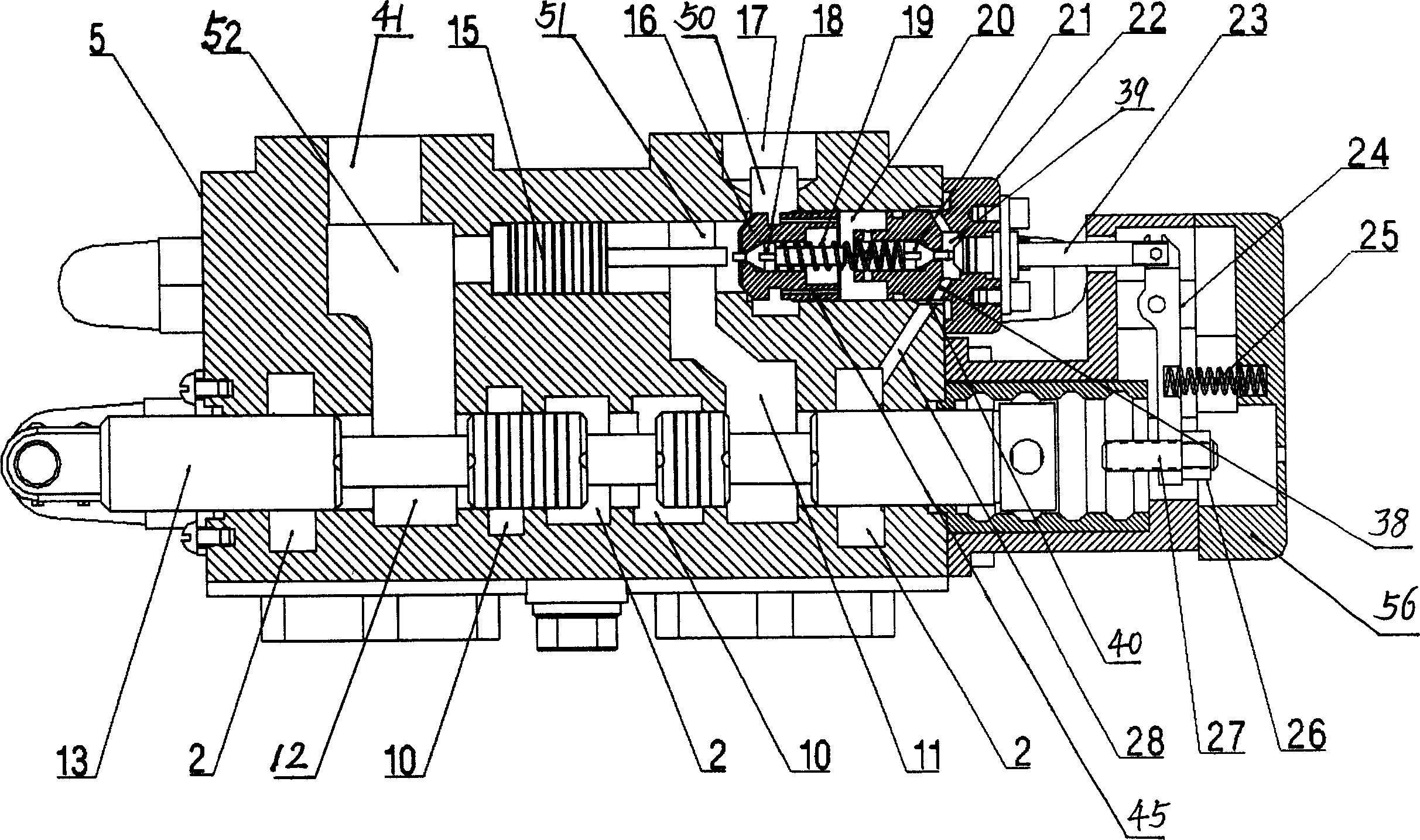

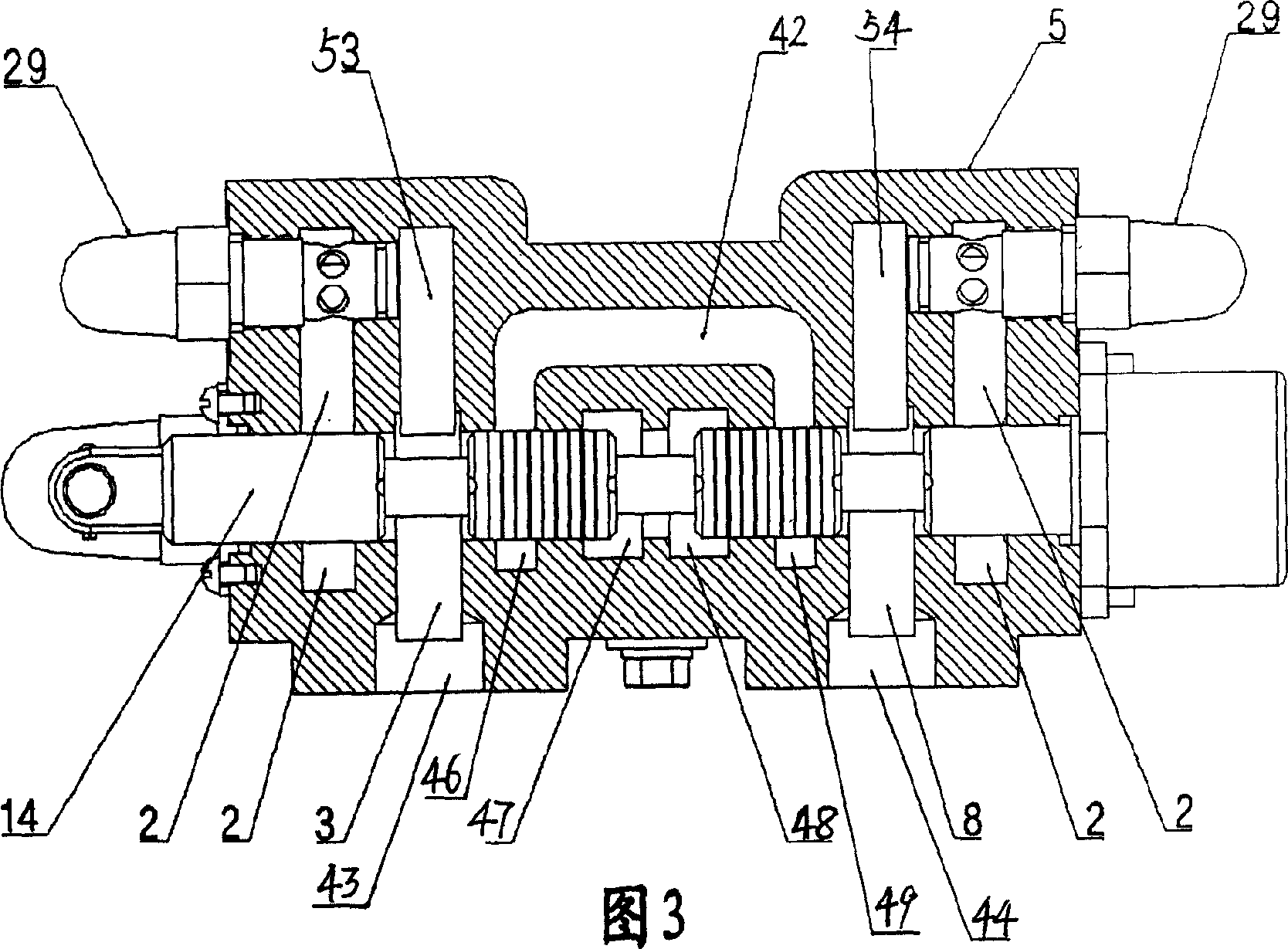

[0020]The integrated manual multi-way reversing valve for the loader shown in the accompanying drawing has three through holes, the first hole 31, the second hole 32, and the third hole 33, along the bottom of the valve body 5. A fifth hole 35 and a sixth hole 36 are oppositely arranged above the hole 32, and a fourth hole 34 is arranged above the third hole 33 and on the same side as the sixth hole 36. In the longitudinal direction near the first hole 31 There is a high-pressure oil inlet 6 on the side, an oil return port 37 is opened on the opposite side of the high-pressure oil inlet 6 and the lower bottom surface of the valve body 5, and an oil return port 37 is opened on the lower bottom surface of the valve body 5 perpendicular to the second hole 32. The unloading bucket oil port 43 and the bucket receiving oil port 44 have a boom lowering oil port 41 and a boom lifting oil port 17 on the upper bottom surface of the valve body 5 perpendicular to the fourth hole 34; The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com