Synthetic resin container with shape retainability

一种合成树脂、容器的技术,应用在刚性容器、容器、包装等方向,能够解决弯曲、无法维持形状、肋条易受热等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

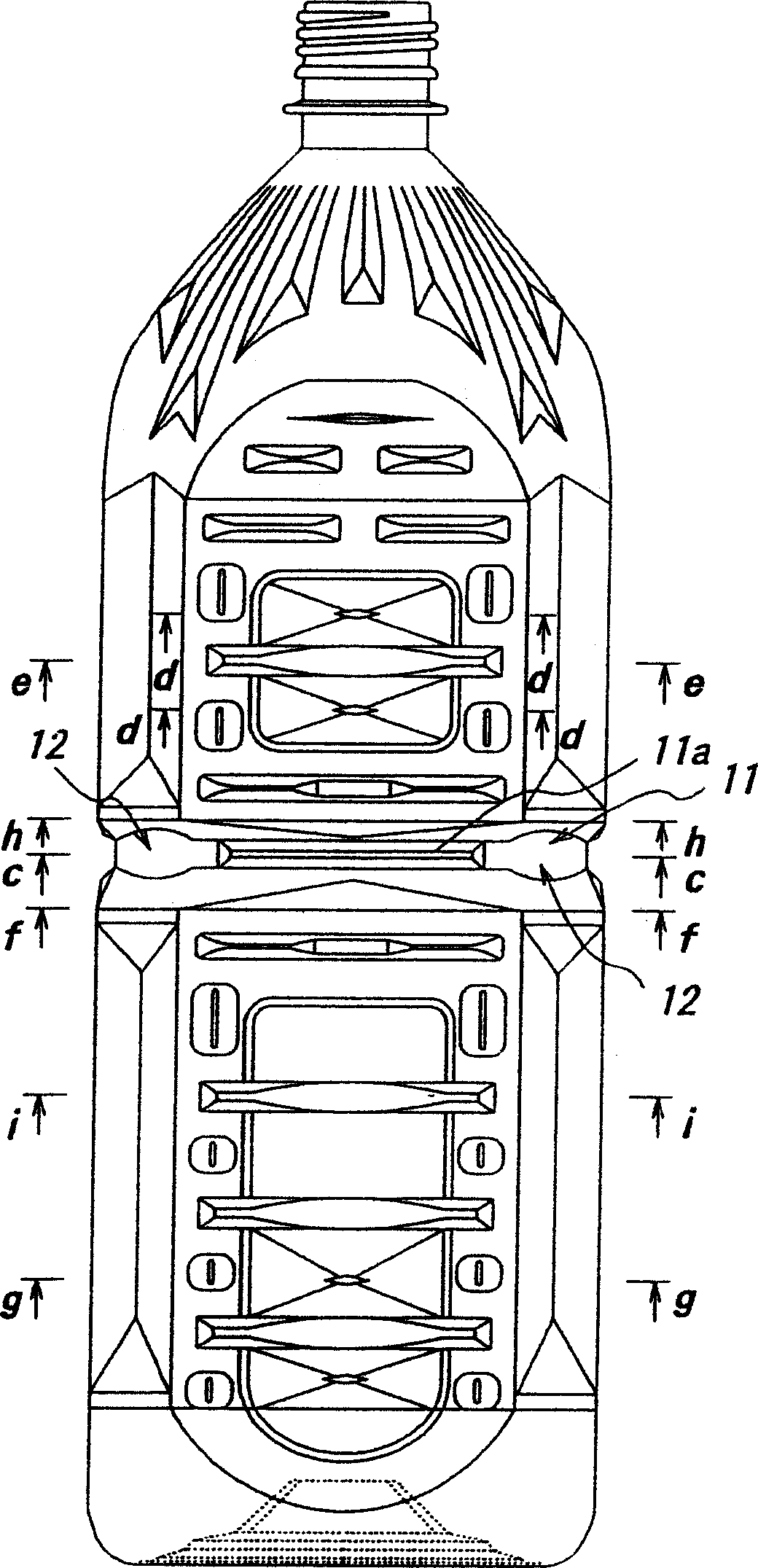

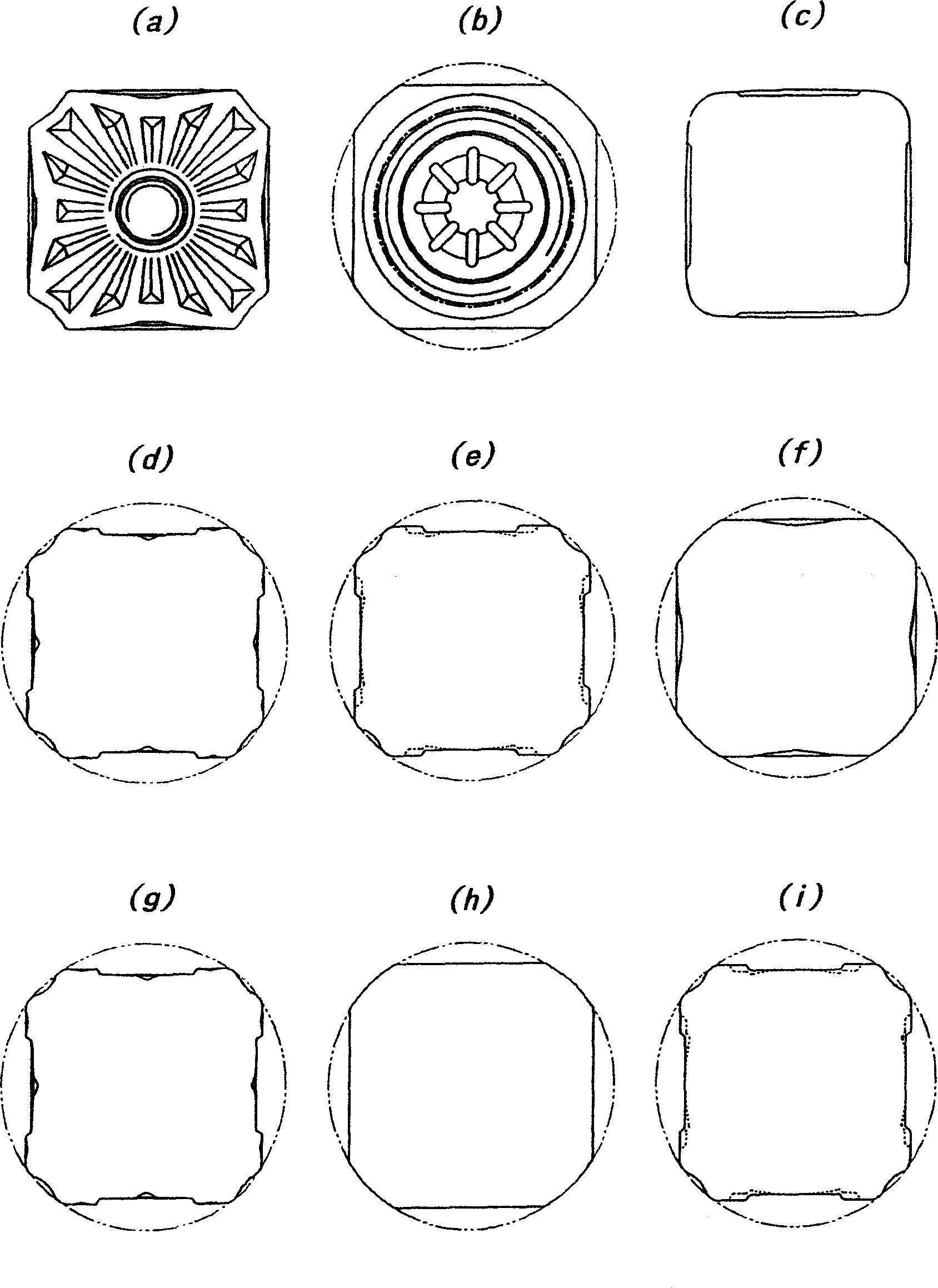

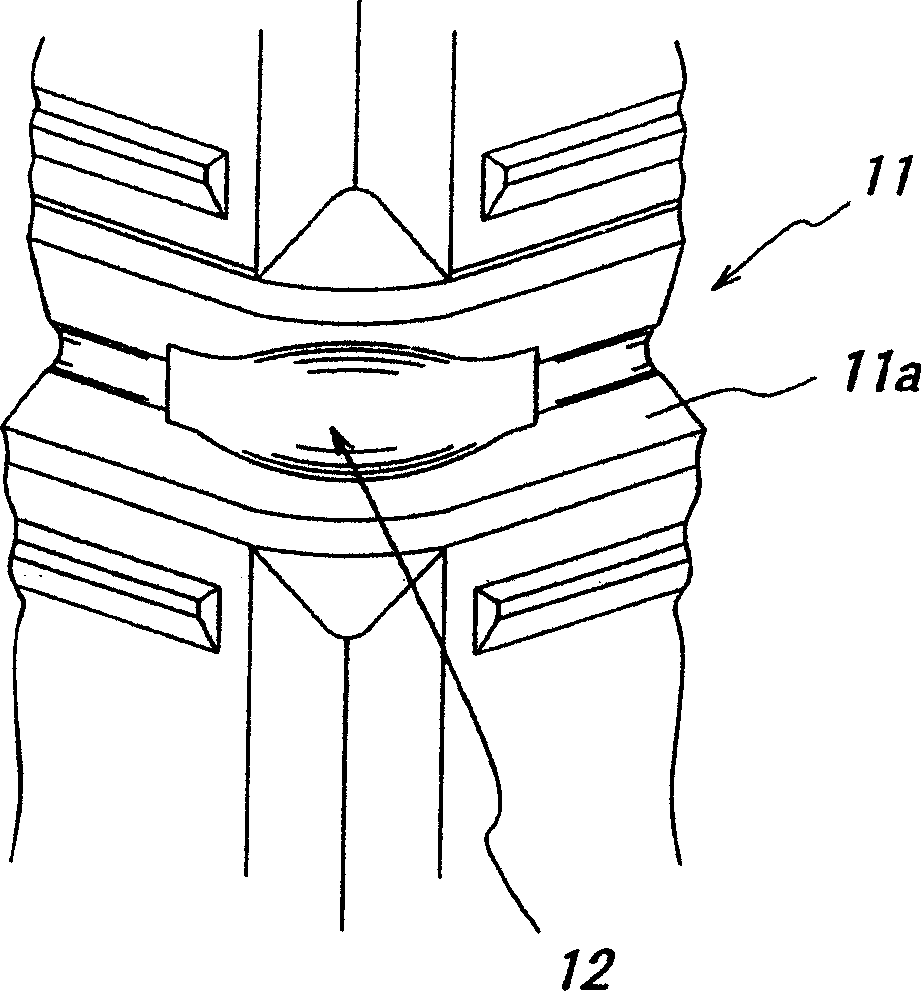

[0055] 1 to 4 are synthetic resin containers according to the first embodiment of the present invention. The container has a capacity of 2.0 liters and has a slightly quadrilateral cross-section. Number 11 is the waist that the container main body is divided into upper and lower sections. The waist 11 is formed by an annular groove 11a that protrudes toward the inside of the container and surrounds the bottle body.

[0056] Reference number 12 is a reinforcing rib whose upper edge is higher than the bottom of the annular groove 11a but lower than the surface of the main body of the container, and its top end is arc-shaped. In this embodiment, reinforcing ribs 12 are provided at the four corners of the container body.

[0057] It is known that the waist which is arranged on the main body of the container and divides it into upper and lower sections has only a simple concave shape, which is originally used to improve the rigidity of the container. However, due to the thinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com