Colour code deviation rectifying analogue photoelectric eye

A photoelectric eye and deviation correction technology, which is applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of inability to detect the size and direction of the offset of the color mark, low accuracy of deviation correction, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

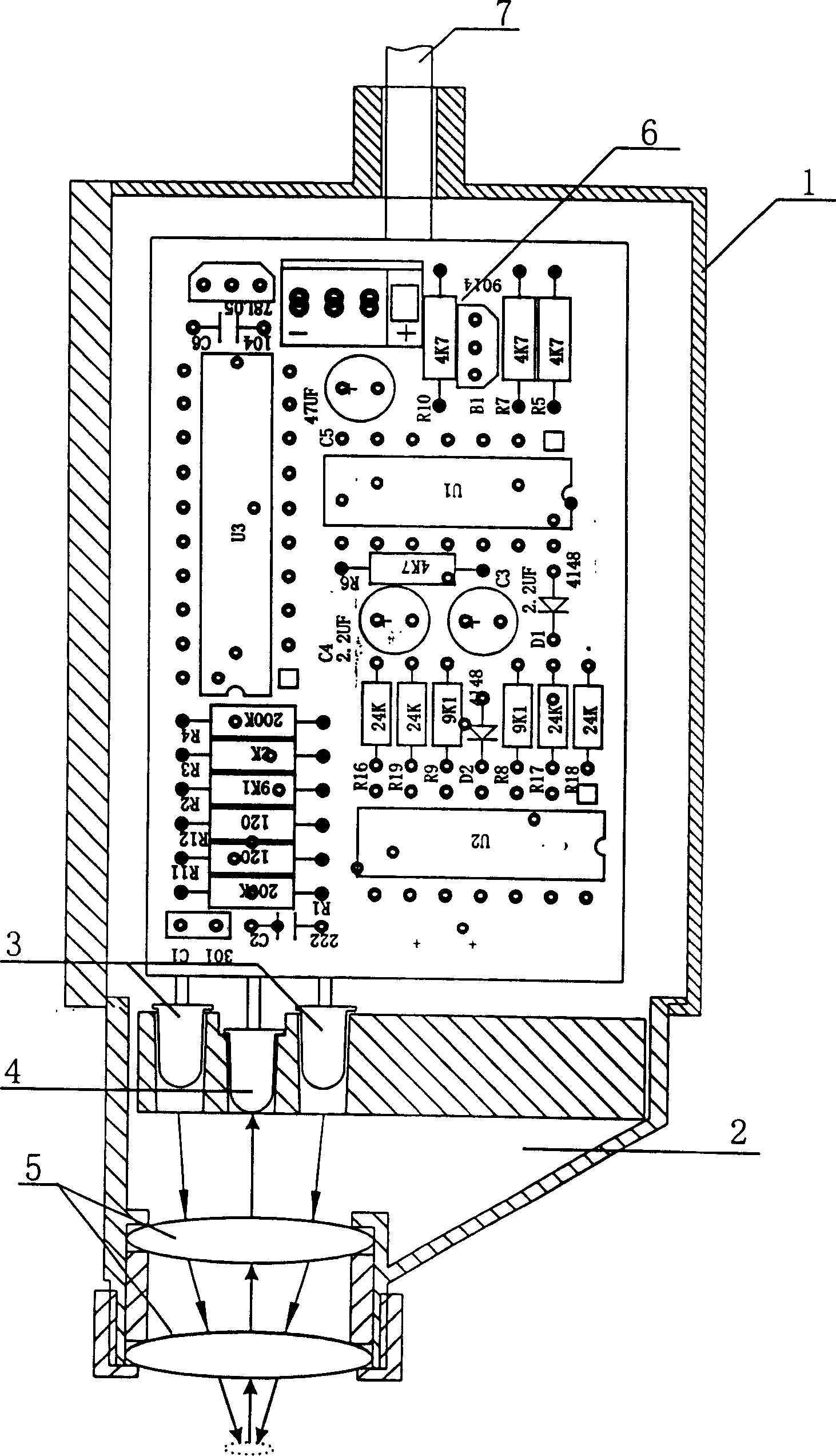

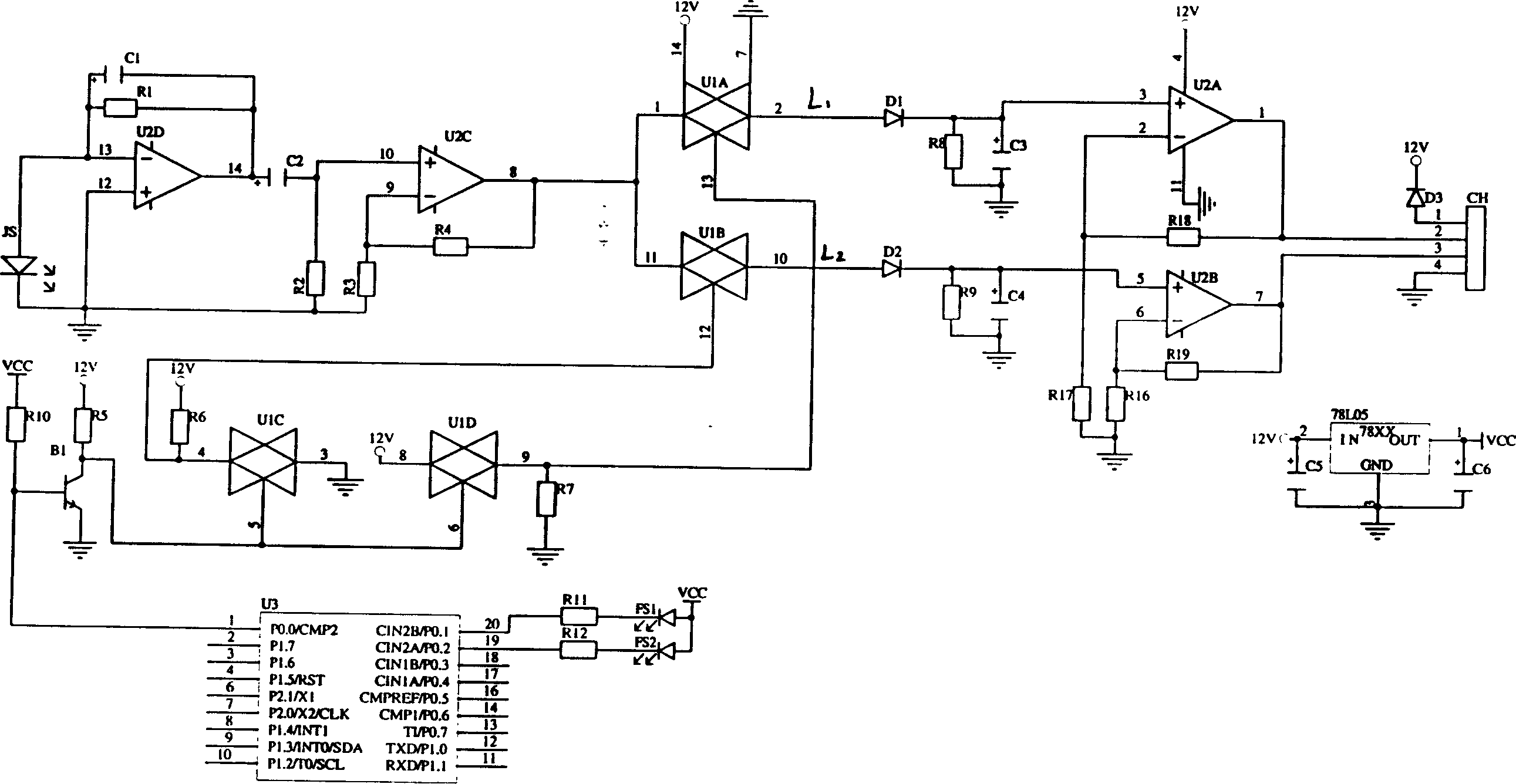

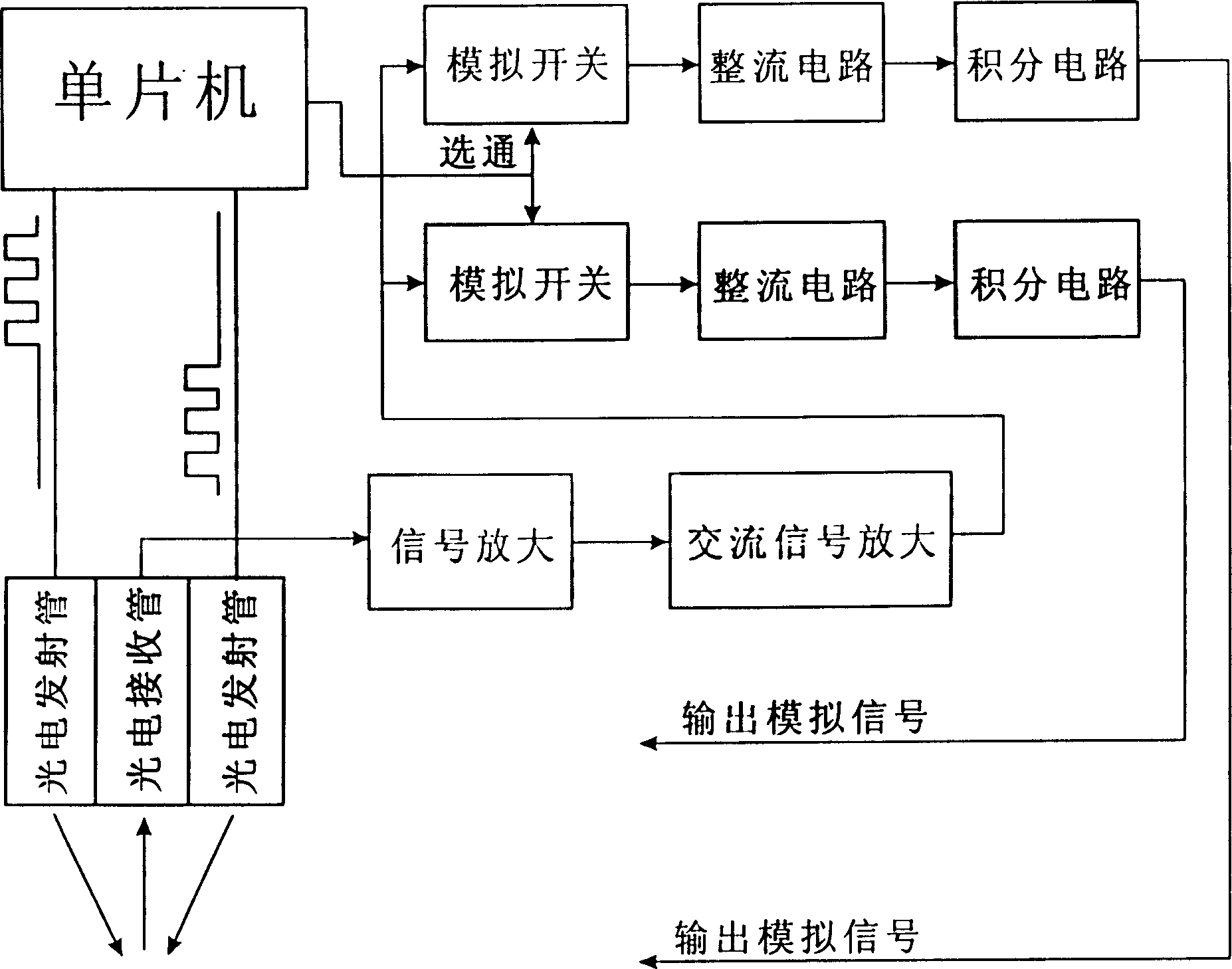

[0009] The drawings show the structure of the present invention and its embodiments, and the relevant details of the embodiments will be further described below in conjunction with the drawings. The color code correction analog photoelectric eye has a housing 1 and a probe 2. The probe 2 is equipped with a convex lens 5, and a circuit board 6 is installed in the housing 1, and the circuit board 6 is provided with two channels for processing analog signals. Circuits L1 and L2. Two photoelectric light-emitting tubes 3 and one photoelectric receiving tube 4 are arranged above the convex lens 5. The photoelectric transmitting tube 3 and the photoelectric receiving tube 4 are electrically connected to the circuit board 6, and the circuit The board 6 is provided with a single-chip microcomputer, the two analog switches U1A, U1B of the two-way processing analog signal circuits L1, L2 are electrically connected to the single-chip microcomputer, and the output ends of the two-way analog si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com