Rectification transformers with self coupling compensation and resournace shield

A rectifier transformer and autotransformer technology, which is applied in harmonic reduction devices and AC networks to reduce harmonics/ripples, etc., can solve the problems of high cost and technical difficulties, and achieve technical difficulties and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

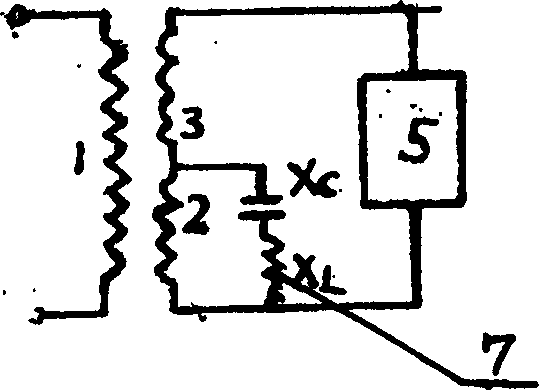

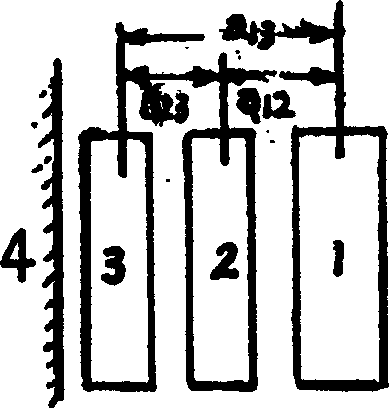

[0019] Such as Figure 1-3 As shown, this embodiment is a single-phase auto-coupling compensation and harmonic shielding rectifier transformer, including primary winding 1, secondary winding and cylindrical core 4, and an auto-coupling tap is drawn in the middle of the secondary winding to divide the secondary winding into windings 2 and 3, The three windings are jointly arranged on the round iron core column 4, the auxiliary winding 3 is arranged on the inner layer close to the cylindrical iron core 4, the original winding 1 is arranged on the outermost layer, and the auxiliary winding 2 is arranged between the auxiliary winding 3 and the original winding 1, The two ends of the secondary winding 2 and the capacitive reactance X C Series inductance X L The two branches of the primary winding 1 are connected to the grid power supply, and the power supply load 5 is connected in parallel with the two secondary windings 2 and 3 in series.

[0020] This embodiment can supply powe...

Embodiment 2

[0027] This embodiment is a three-phase rectifier with self-coupling compensation and harmonic shielding. The primary winding can be star-shaped or triangular (not shown in the figure), and the secondary winding can be a Yanbian triangle with a middle lead-out tap, such as Figure 4 As shown, the Yanbian endpoints u, v, w are respectively connected to the three-phase rectifier bridge 6 on the valve side, forming a six-pulse rectification output and connected to the power supply load 5; the triangular three-phase terminals a, b, c are connected to the compensation capacitor Sense L C Components are connected. Its triangular phase winding is equivalent to the common winding 2 of the autotransformer, which plays a shielding role in filtering, and the extension winding is equivalent to the series winding 3 of the autotransformer; The iron core 4 is arranged concentrically. The flux generated by the harmonic currents, similar to the single-phase rectifier transformer described ab...

Embodiment 3

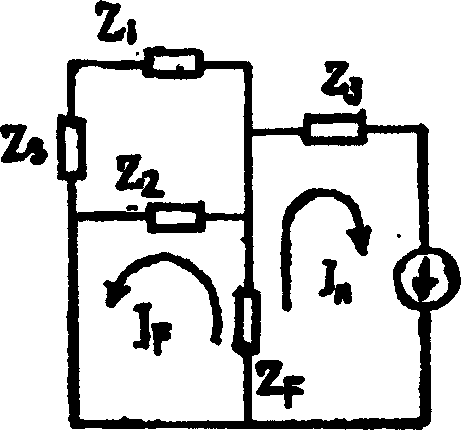

[0031] Embodiment 3: This embodiment is a 6-phase 12-pulse self-coupling compensation and harmonic shielding rectifier transformer composed of two extension triangles on the secondary side. Such as Figure 6 As shown, the two sets of three-phase outputs of the secondary winding are respectively connected to their respective three-phase rectification devices 6. The two rectification devices 6 contain thyristors that can form 12 pulsating phases, and the potential difference between phases is 30°. The self-coupling compensation and self-coupling taps of the shielding filter drawn out in the center are connected with the additional compensation and filtering equipment 7, that is, the capacitive-inductive branch L-C; the original rectifier transformer usually installs the compensation and filtering equipment on the grid-side high-voltage bus according to the traditional wiring , the present invention moves the compensation and filter equipment 7 from the network side to the side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com