Electroluminescent element and its manufacturing method

A technology of electroluminescent components and manufacturing methods, which is applied in the direction of electroluminescent light sources, electrical components, semiconductor/solid-state device manufacturing, etc., and can solve problems such as component characteristic degradation, easy oxidation, and reduced electron injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0058] Evaluation of the formed organic EL element will be described below by experiment.

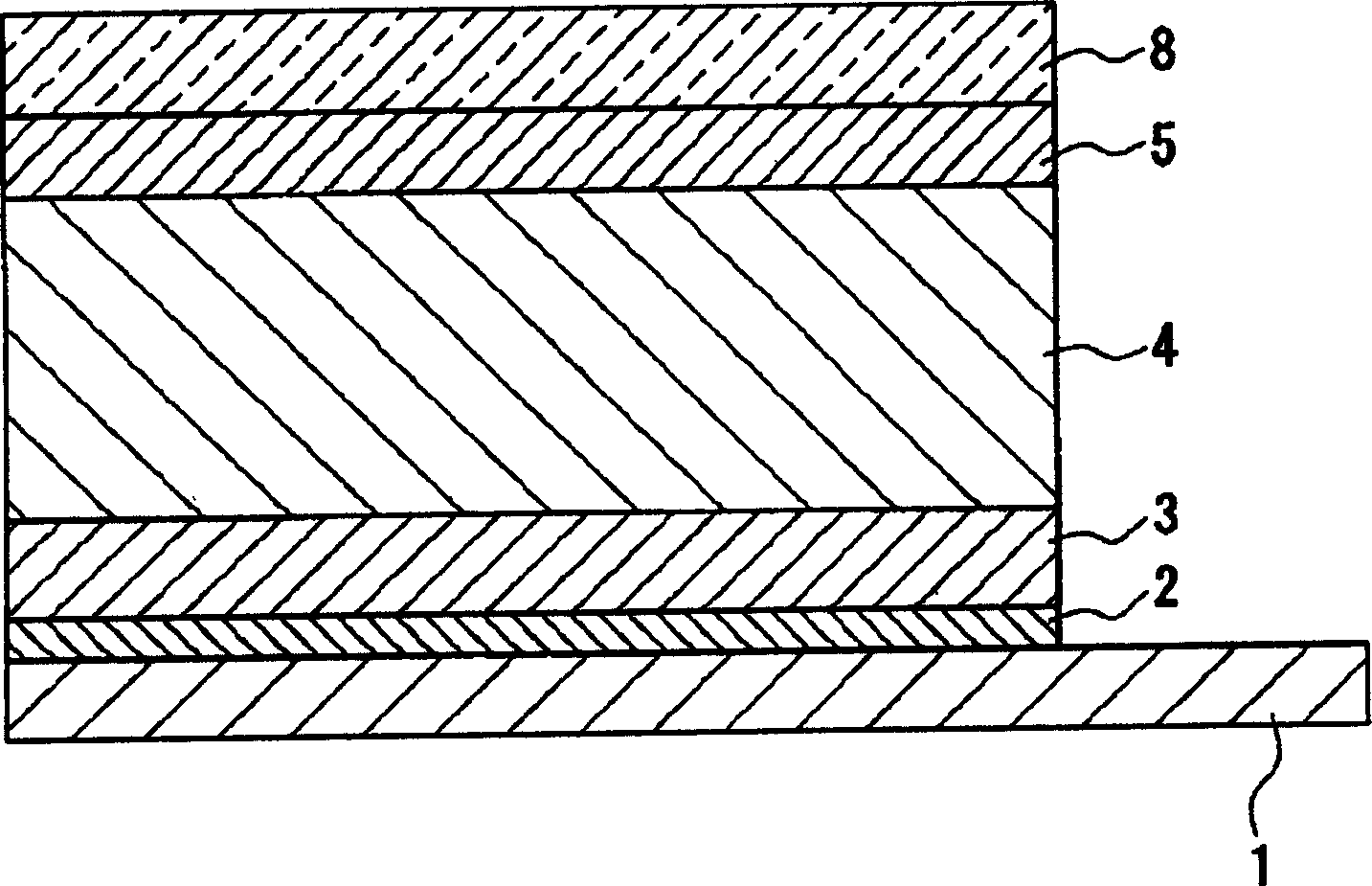

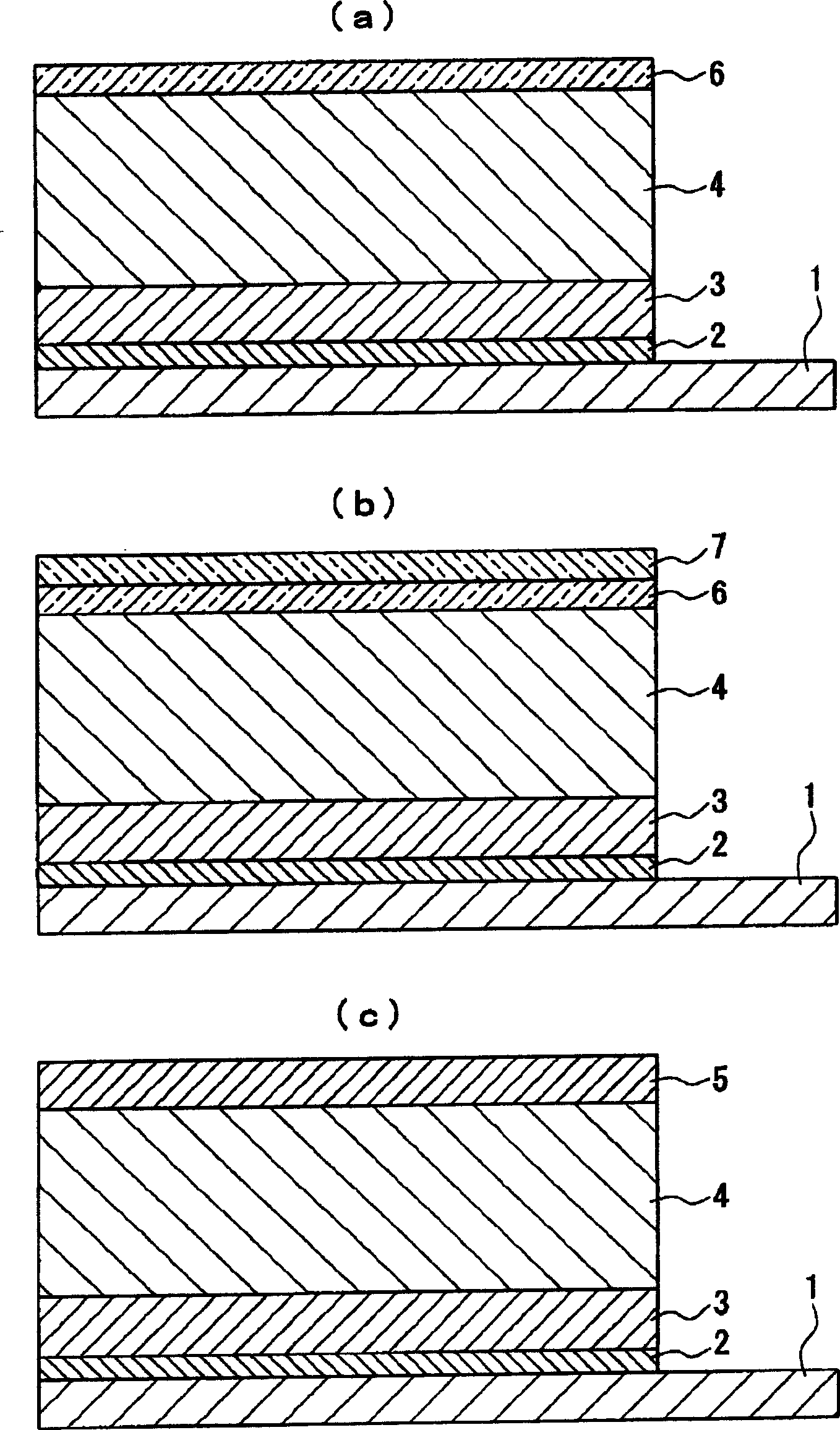

[0059] Here, as an organic EL element, the above-mentioned transparent conductive film 8 is not formed, and a 200 nm thick Al film is vapor-deposited as the reducing metal layer 7, so that the Al film has the function as the reducing metal layer 7 and serves as an electrode (transparent conductive layer 7). Two-sided function of membrane 8). For the film thickness of the metal compound layer 6 , that is, the film thickness of LiF, four types are formed, 0.5 nm; 1 nm; 3 nm; 5 nm. For the electrode 2, a 100 nm thick film was formed with ITO, and for the substrate 1, 1 nm thick ground glass was used. For the hole injection layer 3 and the light emitting layer 4, those shown in the above-mentioned embodiment mode can be used.

[0060] When measuring the luminous intensity of the obtained four organic EL elements, the luminous intensity of the LiF film with a thickness of 0.5nm is 5000cd / m...

experiment example 2

[0063] A LiF film was formed as the metal compound layer 6 with a thickness of 2 nm, 4 nm, 6 nm, 10 nm, and 12 nm, respectively. Other than that, the configuration was the same as in Example 1, and five types of organic EL elements were produced.

[0064] When the luminous efficiency (maximum efficiency) of the obtained five organic EL elements was measured, the luminous efficiency of LiF with a film thickness of 2nm was 9.21m / W, that of 4nm was 6.41m / W, and that of 6nm was 4.41m / W. 10nm is 3.71m / W, and 12nm is considered non-luminous.

[0065] From this result, it is considered that when the metal compound layer 6 is formed thicker than 10 nm, the effect of improving the electron injection property cannot be obtained after the reduction reaction. Therefore, regarding the thickness of the metal compound layer 6, it has been confirmed that 10 nm is preferably taken as its upper limit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com