Method of upgrading gravel and/or dirt roads and a composite road resulting therefrom

A gravel and road technology, applied in the field of road reconstruction and laying, can solve the problem of no space to widen roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

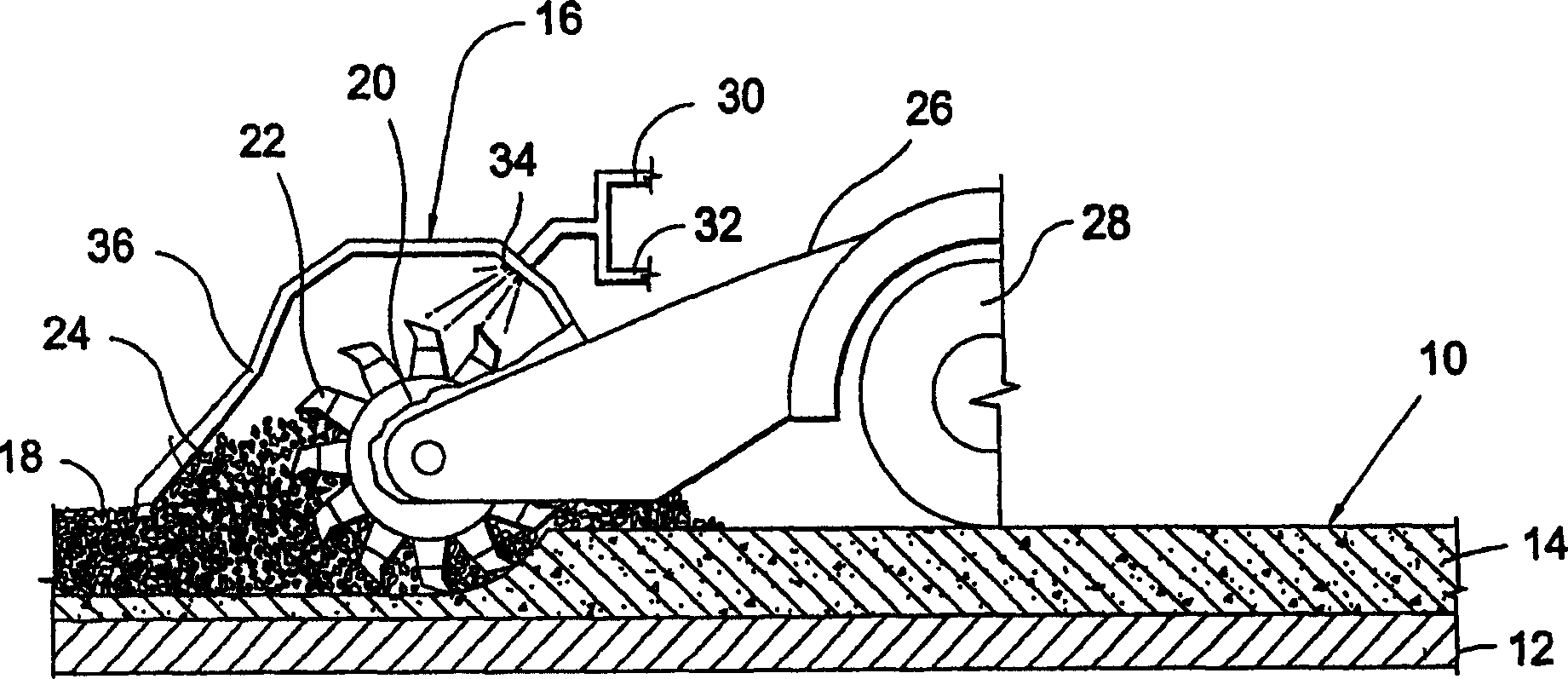

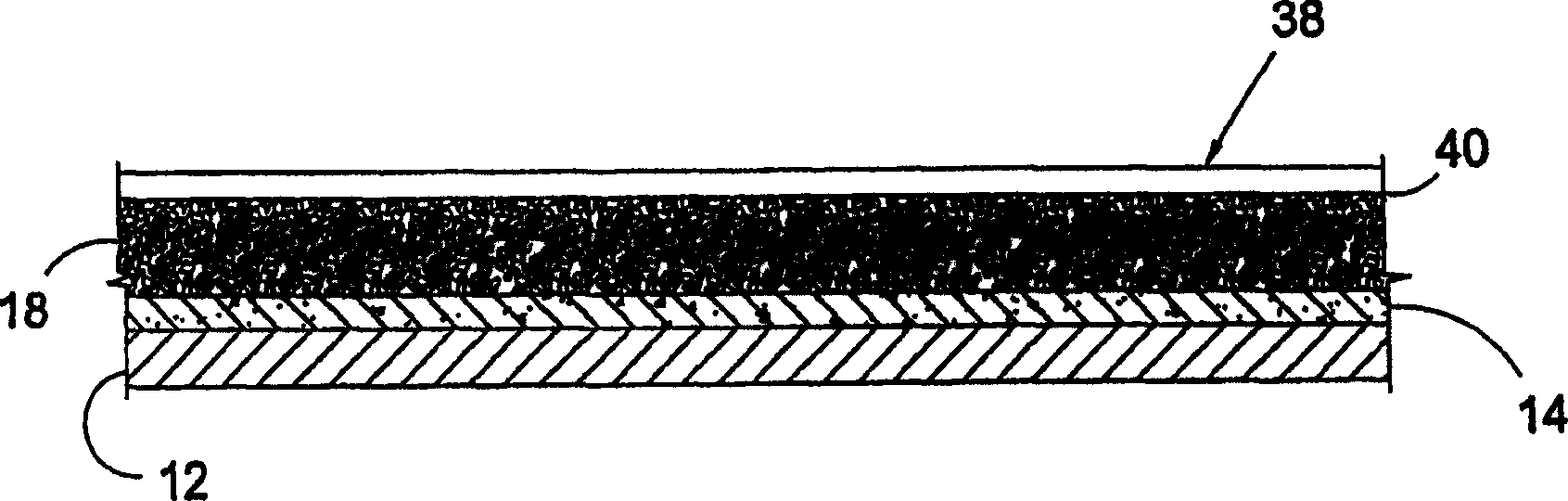

[0018] see figure 1 , the gravel or dirt road to be laid is generally indicated by reference numeral 10 . The road includes a road base 12 and a gravel and / or soil base 14 of naturally occurring soil. The method of the present invention utilizes apparatus 16 throughout to form emulsion stabilization layer 18 . The device 16 is a recovery device and includes a milling head 20 with teeth 22 capable of breaking up the base layer 14 , sometimes parts of the layer 12 , into loose material (gravel / soil) 24 in order to start rebuilding the road 10 . Such as figure 1 As shown, device 16 moves to the right side of the page. The milling head 20 is connected to a motorized unit 26 with wheels 28 . The plant 16 also includes a line 30 for carrying the bitumen emulsion and a line 32 for carrying water. The emulsion and sometimes water are sprayed onto the gravel / soil 24 through nozzle 34 which is connected to lines 30 and 32 . The mixing chamber 36, which is part of the apparatus 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com