Lead and zinc sulfide ore in situ electric potential flotation process

A technology of lead-zinc sulfide and sulfide ore, which is applied in flotation, solid separation, etc., can solve the problems of difficult ore particles uniformly meeting the requirements, difficult to stabilize potential, and poor conductivity of ore particles, so as to improve the selectivity of mineral separation and reduce the Medium ore circulation and the effect of increasing the flotation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

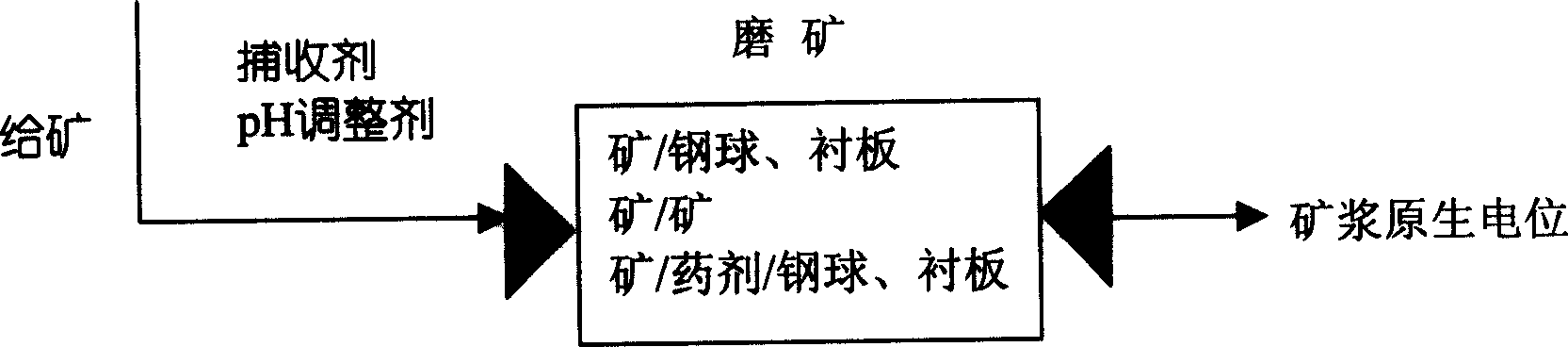

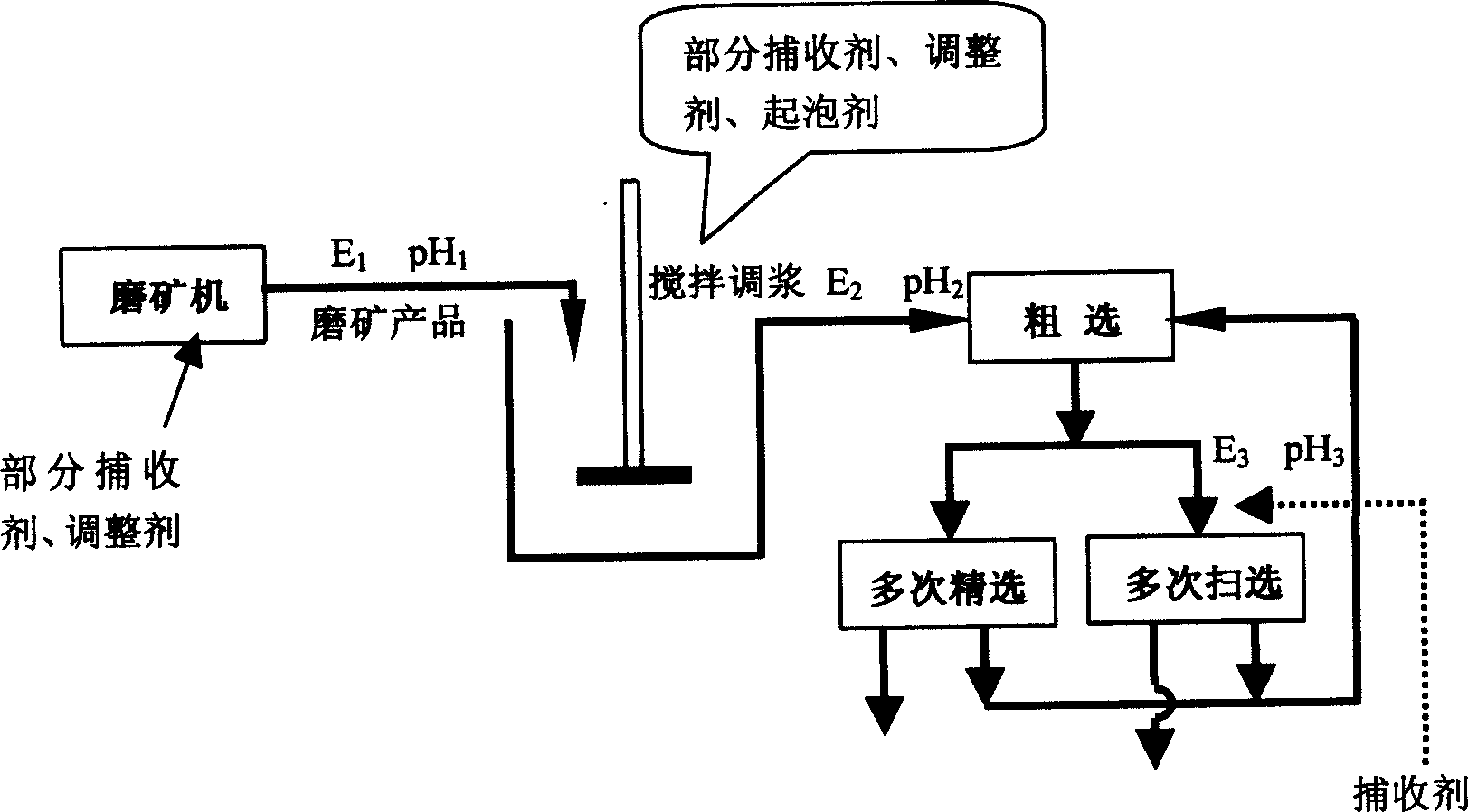

Method used

Image

Examples

Embodiment 1

[0013] The annual processing of raw ore is 1 million tons. The ore is a high-sulfur lead-zinc ore. The sulfide ore is finely distributed and closely related, so it is difficult to sort. The lead-zinc flotation process is as follows: lead is selected first, the lead rapid separation foam product is subjected to secondary selection to obtain lead concentrate 1, the lead fast separation tailings are subjected to secondary coarsening, primary sweep, rough separation foam product is regrinded and refined five times. The lead concentrate 2 is selected, and the lead concentrate 1 and the lead concentrate 2 are combined to obtain the total lead concentrate; the lead tailings are subjected to zinc quick separation for three times to obtain zinc concentrate 1, and the zinc quick separation tailings are subjected to secondary coarsening and two Sweeping and Sijing get zinc concentrate 2, zinc concentrate 1 and zinc concentrate 2 are combined to get total zinc concentrate. Potential-regul...

Embodiment 2

[0020] The medium-sized lead-zinc mine with a daily processing capacity of 900 tons of raw ore is divided into two series of production. Before applying the native potential to regulate the flotation process, the chemical system is: under the natural pH value of the pulp, zinc sulfate (1.1Kg / t) and sodium sulfite (0.7Kg / t) are used as inhibitors of zinc and sulfur, butyl ammonium black drug and Aniline and black drug combination as collector (60g / t) preferentially flotation lead; lead tail selection for zinc use lime as pH adjuster to suppress sulfur, copper sulfate as activator, 310 compound xanthate as collector; zinc tail selection for sulfur Use 310 compound xanthate as collector and RB3 as foaming agent. The lead-zinc flotation process is as follows: two series, lead selection is preferred, the lead quick separation foam product is subjected to one-time selection to obtain lead concentrate 1, the lead quick-selection tailings are subjected to one rough selection, three ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com