A method for flocculation and precipitation of fine-grained chalcopyrite by using a mixed flocculant

A flocculant and chalcopyrite technology, which is applied in the field of fine-grained chalcopyrite flocculation and sedimentation, can solve the problems of clogging of ceramic panels and increase the cost of filtration, and achieve the effects of reducing muddy running, good economic benefits and effective sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

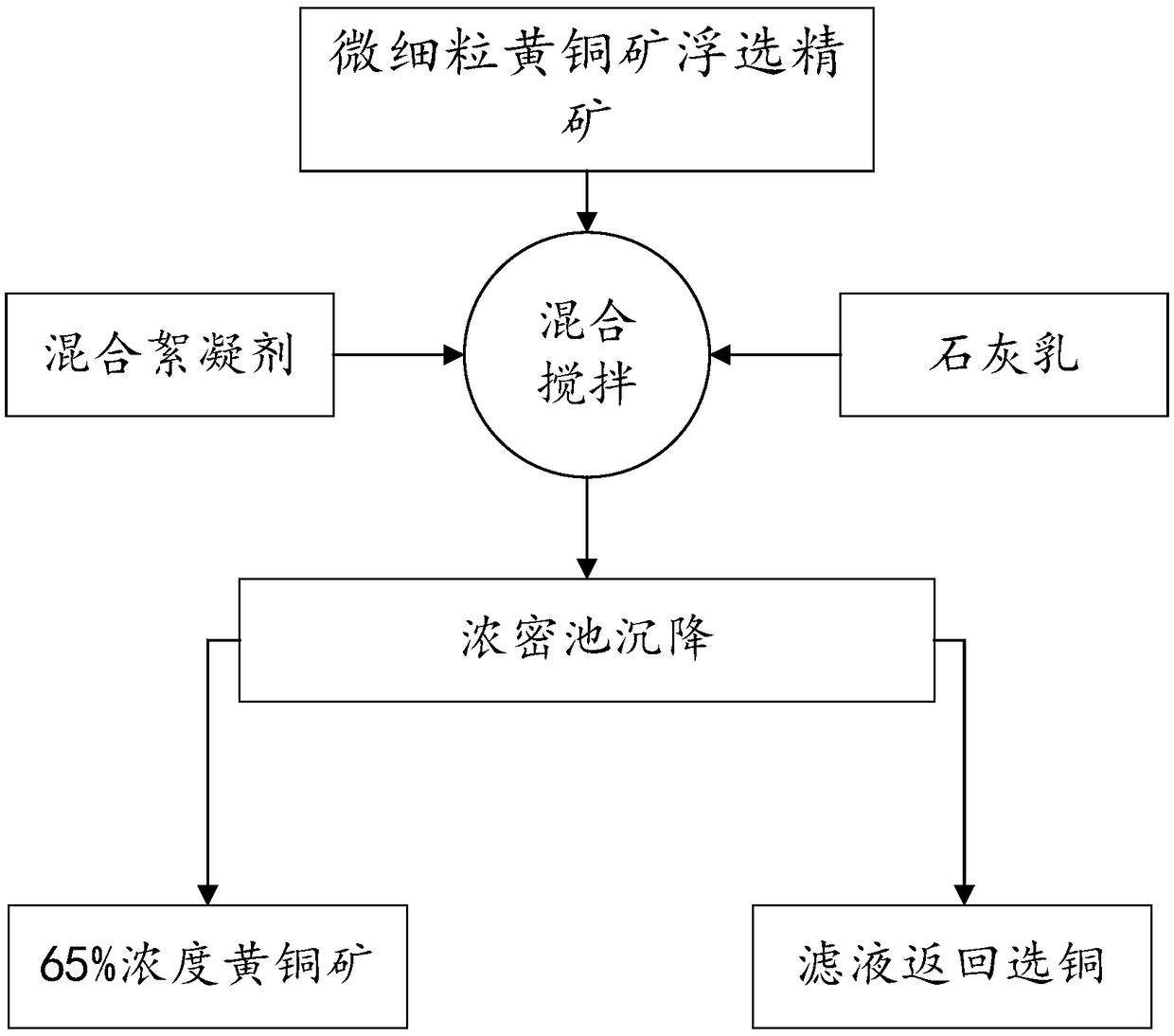

Method used

Image

Examples

Embodiment 1

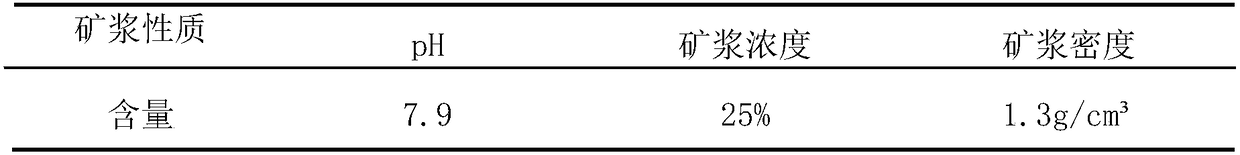

[0026] The properties of the slurry were analyzed for the on-site flotation sulfur concentrate of a copper-sulfur separation plant in the Yangtze River Basin. The pH of the slurry was tested, wet sieved (200 mesh sieve was used), dried, and weighed. The measured properties of the pulp are as follows:

[0027] Table 1 Slurry properties of chalcopyrite concentrate

[0028]

[0029] After filtering and drying the under-screen product of the wet sieve, the sample was mixed and shrunk, and the ore sample was analyzed with a laser particle size analyzer to analyze the composition of the particle size distribution of the material. The particle size distribution of the copper concentrate slurry was measured as follows:

[0030] Table 2 Copper concentrate material particle size composition

[0031]

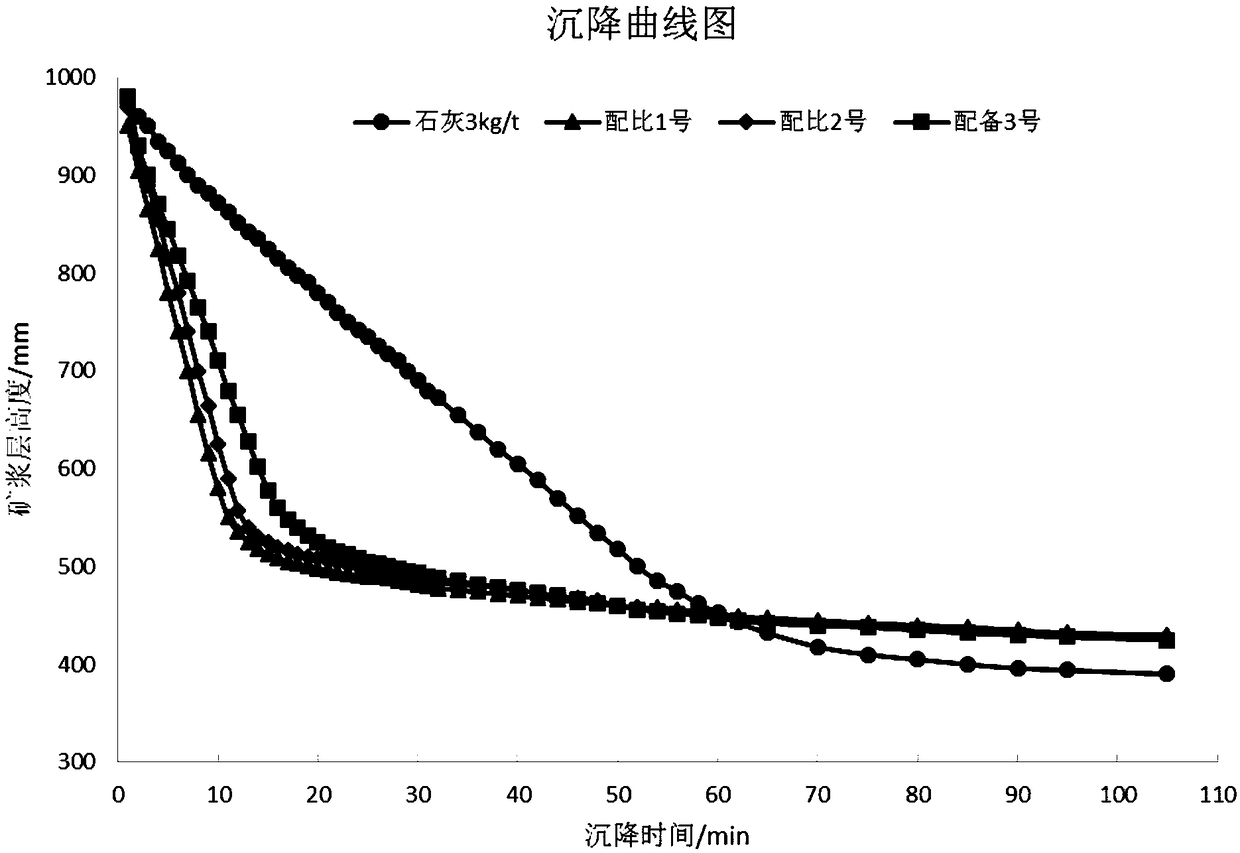

[0032] According to the properties of the pulp, the following groups of comparative test conditions are used, as shown in Table 3:

[0033] Table 3 flocculant ratio (mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com