Slit double gap buncher and method for improved ion bunching in an ion implantation system

A technology of beam concentrator and ion beam, which is applied in the direction of deflecting/concentrating/focusing the beam current with electric/magnetic devices, discharge tubes, accelerators, etc., and can solve ion loss (such as not provided to the workpiece, long time, etc.) question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

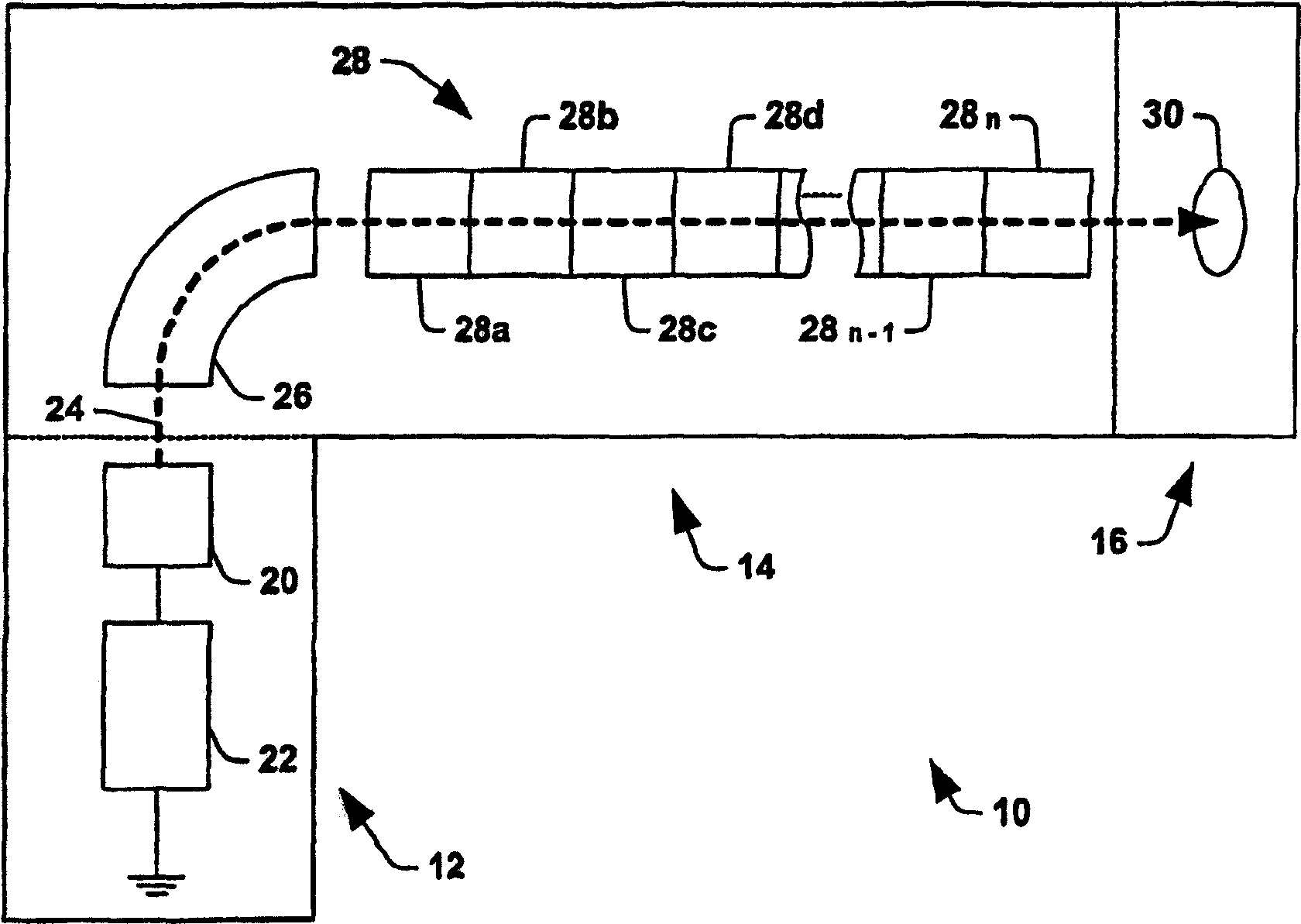

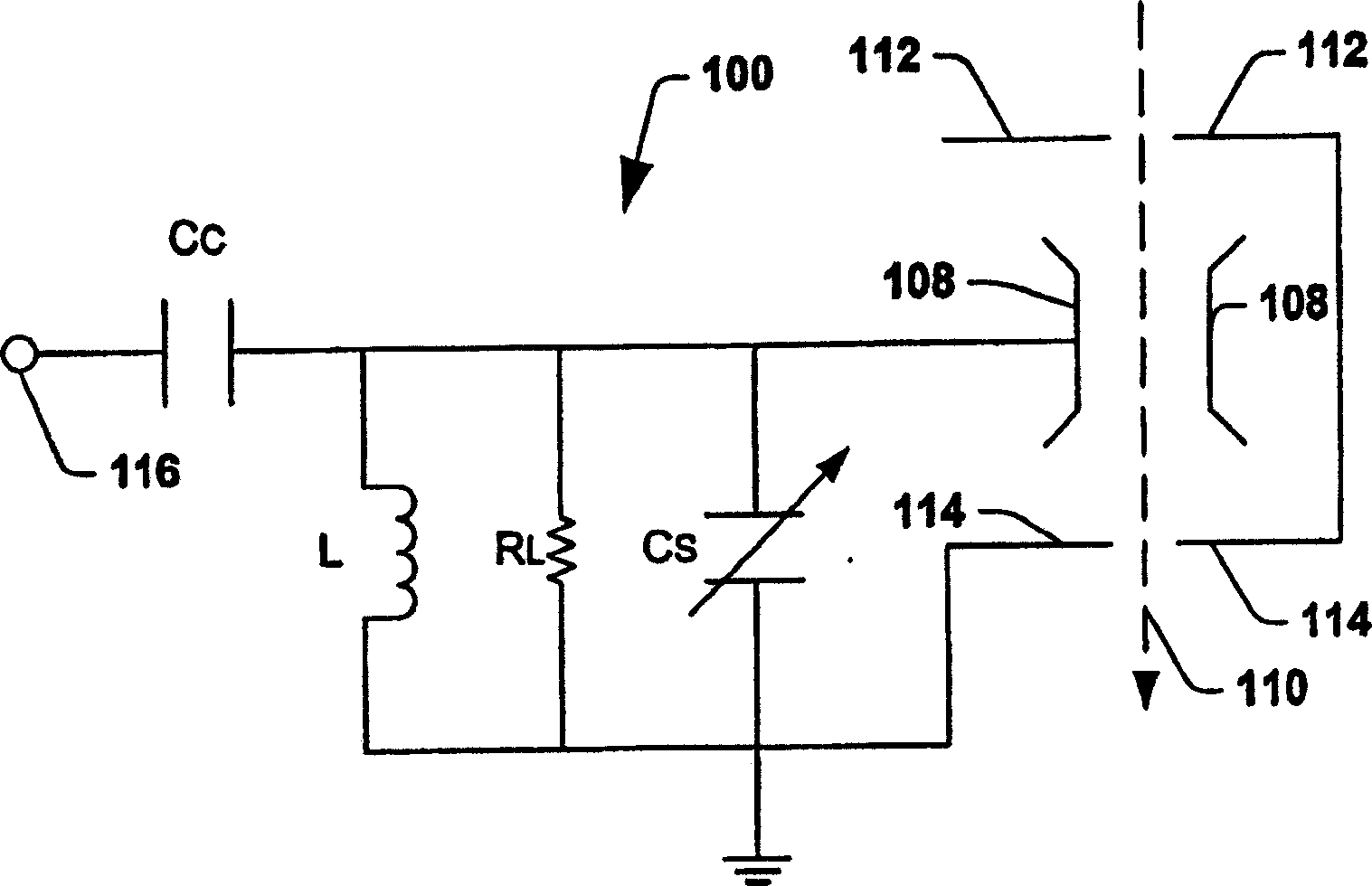

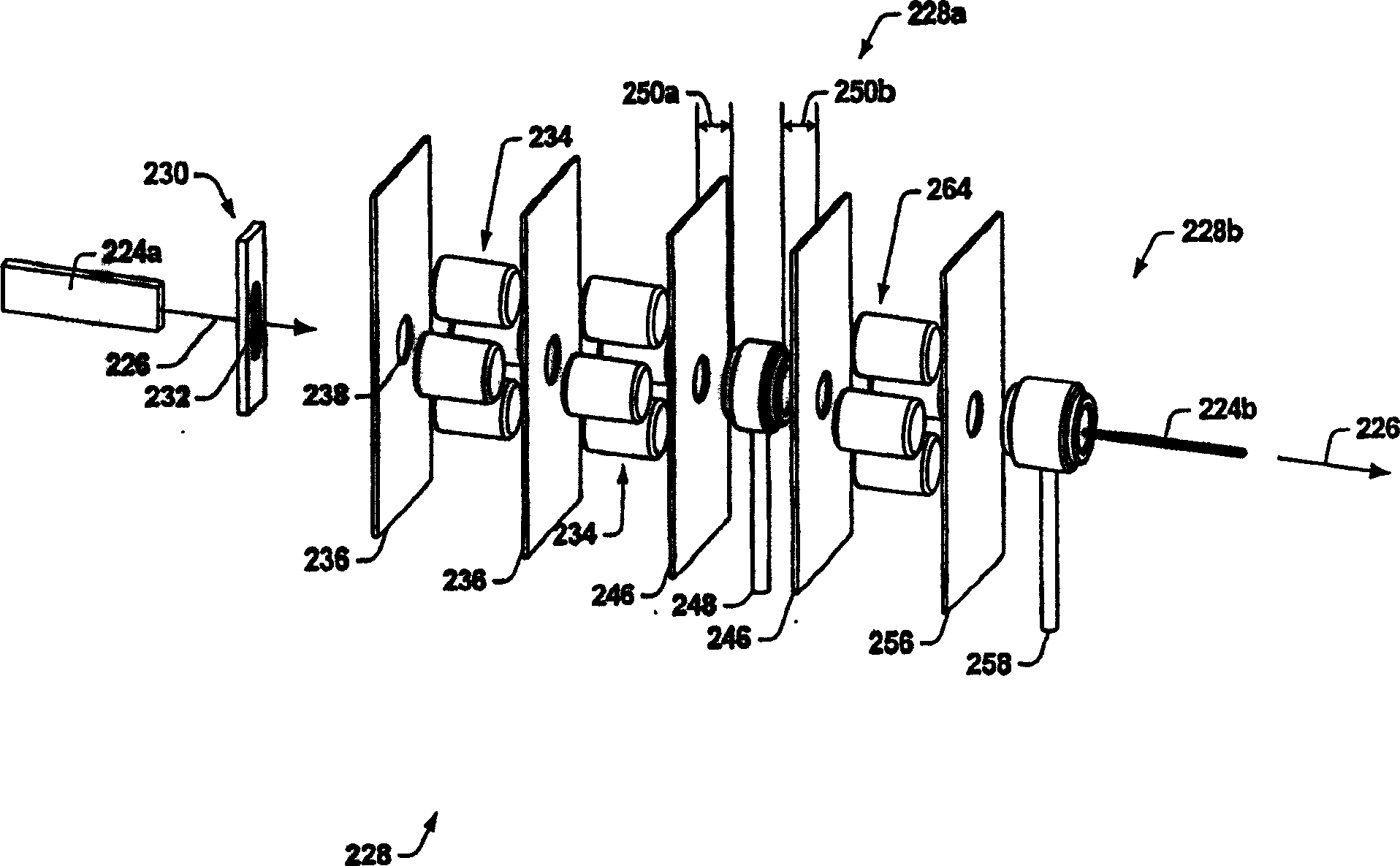

[0020] The present invention will be described below with reference to the accompanying drawings, in which similar elements are marked with similar reference numerals. A dedicated ion buncher section is provided for bunching ions in the ion implantation system. The ion buncher section may be used in the linac upstream of the accelerating section to provide an ion beam or ion packet such that ion losses in the linac are reduced. The buncher section can operate at lower energy levels than the subsequent accelerator section and can also provide a drift region to facilitate ion bunching. The present invention also includes an asymmetric double-gap buncher section, and a slit buncher section to further improve ion implantation efficiency. Methods for accelerating ions in a linear accelerator of an ion implanter are also described below.

[0021] In order to provide context for the features of the present invention, a linear accelerator module (such as figure 1 The conventional i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com