Method for manufacturing optical fiber preform

A manufacturing method and optical fiber base material technology, applied in manufacturing tools, glass manufacturing equipment, glass production, etc., can solve problems such as increased offset, reduce core wire eccentricity, improve scattering, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, specific embodiments of the present invention will be described with reference to the drawings.

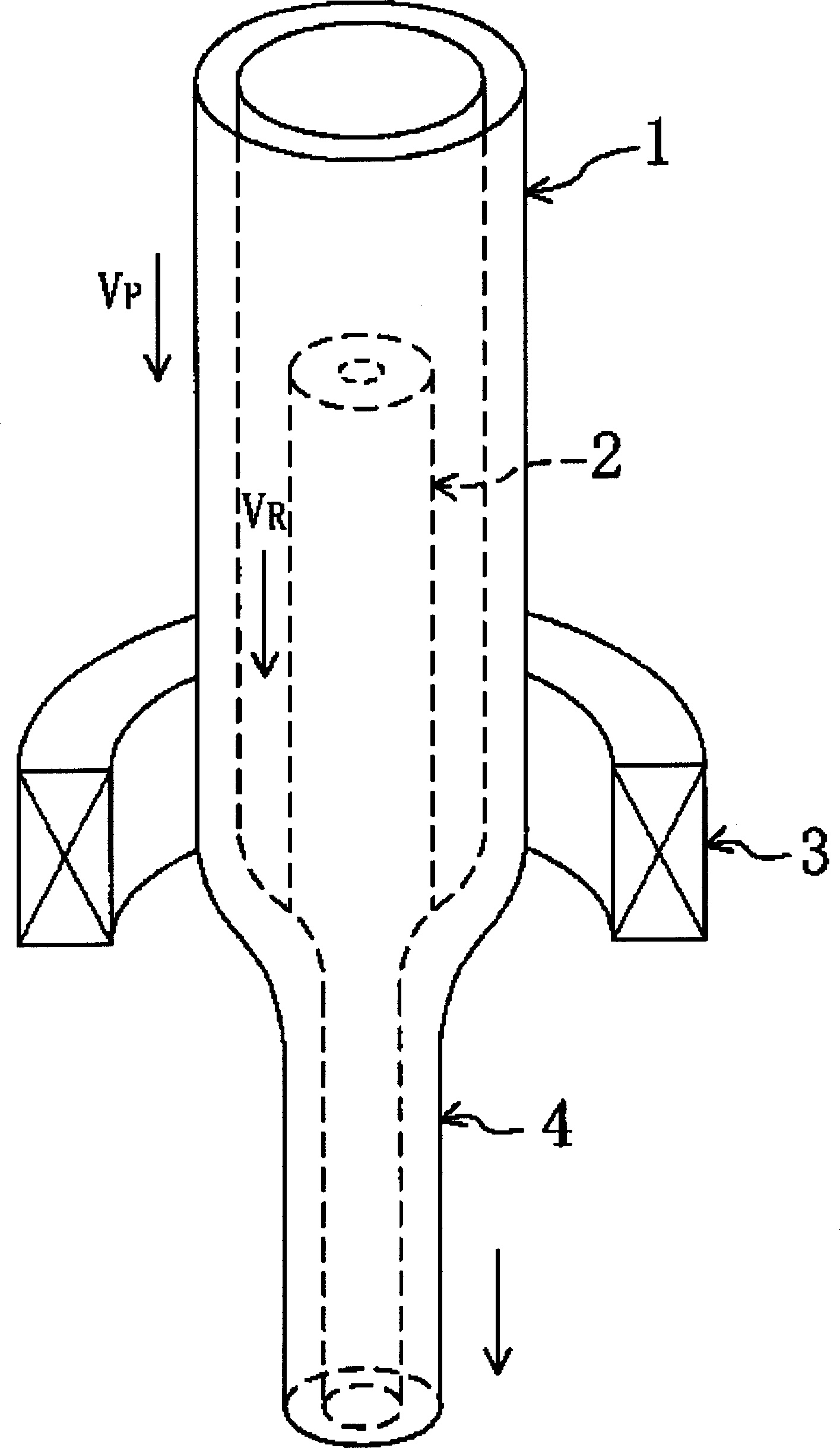

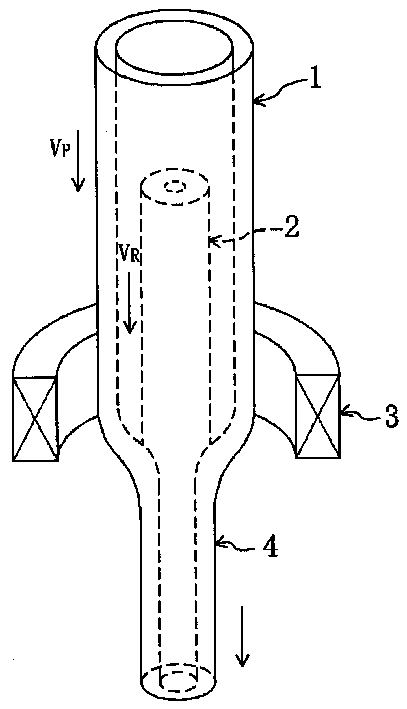

[0040] Fig. 1 shows the state during manufacture of an optical fiber preform. 1 is a glass tube for cladding, 2 is a glass rod for a core wire or a core wire and a clad, and 3 is a heater for heating both the above-mentioned glass tube 1 and glass rod 2 . As the above-mentioned glass tube 1, a glass tube produced by an OVD method or the like can be used. The above-mentioned glass rod 2 can be obtained by sintering the glass particle deposition body deposited with glass particles by the VAD method, and then stretching, or using the MVCD method to form a glass core on the inner surface of the cladding tube, and the center is solid. . Specifically, a carbon resistance heating furnace or a high-frequency induction heating furnace can be used as the heating furnace having the heater 3 described above.

[0041] In addition, the upper ends of the above-mentioned glass tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com