Eddy current inspection technique

A current and eddy current technology, used in electromagnetic measurement devices, electrical/magnetic thickness measurement, measurement devices, etc., can solve the problems of local wall thickness reduction, inability to detect corrosion points, and size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, the same reference numerals denote the same components.

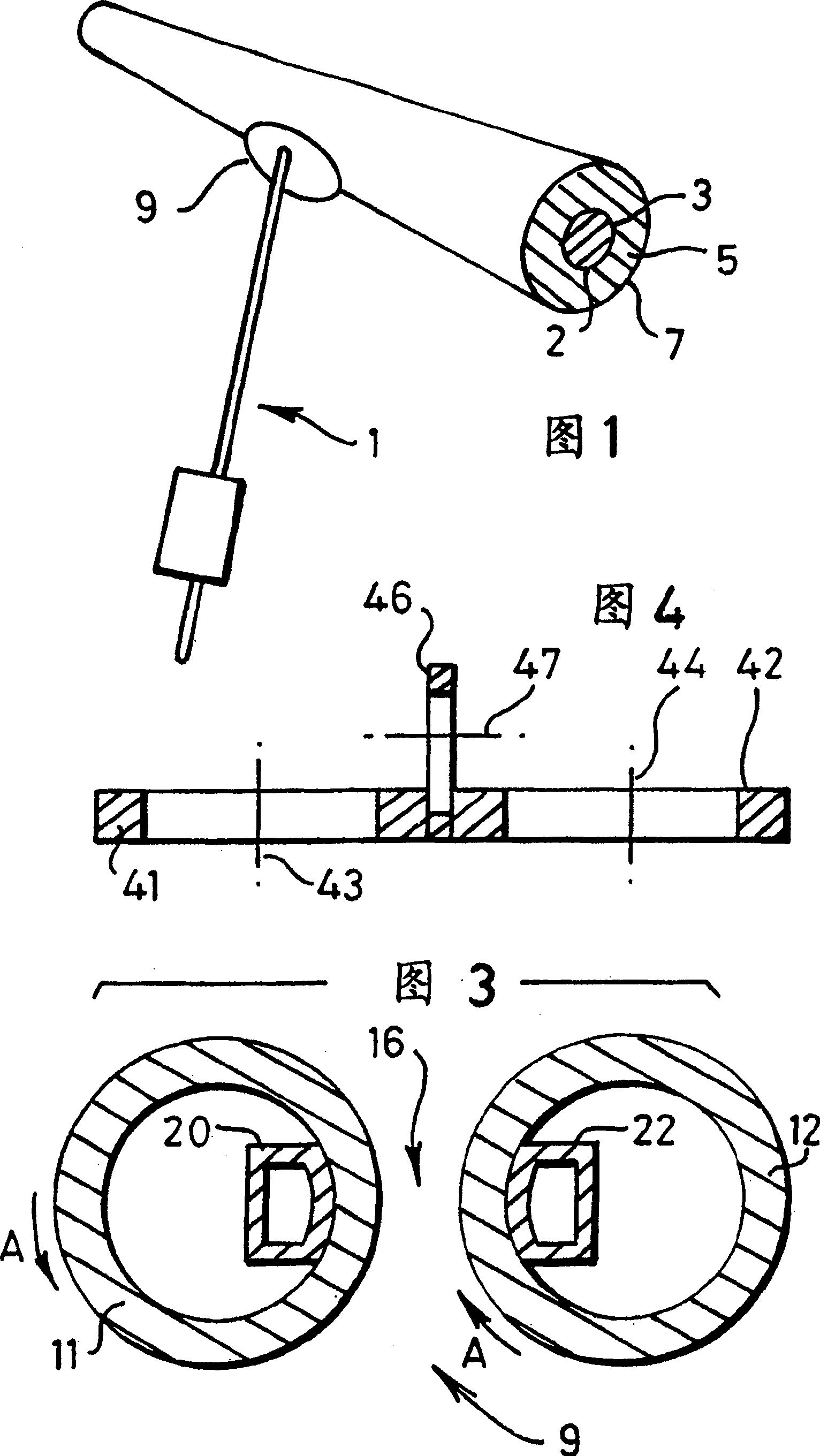

[0026] FIG. 1 shows a probe 1 for detecting objects made of conductive materials. This probe 1 can be used to detect the thickness of a pipe wall 2 on a pipe 3 to detect the corrosion state on the pipe wall 2 . Corrosion may occur at the outer or inner surface of the pipe wall 2 . A layer of insulating material layer 5 is arranged around the pipe 3, and the outside of the insulating material layer 5 is covered with a sleeve 7 made of thin metal steel. The probe 1 comprises a means 9 for carrying out the detection of an object consisting of electrically conductive material, and during normal operation the means 9 is held in position opposite the outer surface of the steel sleeve 7.

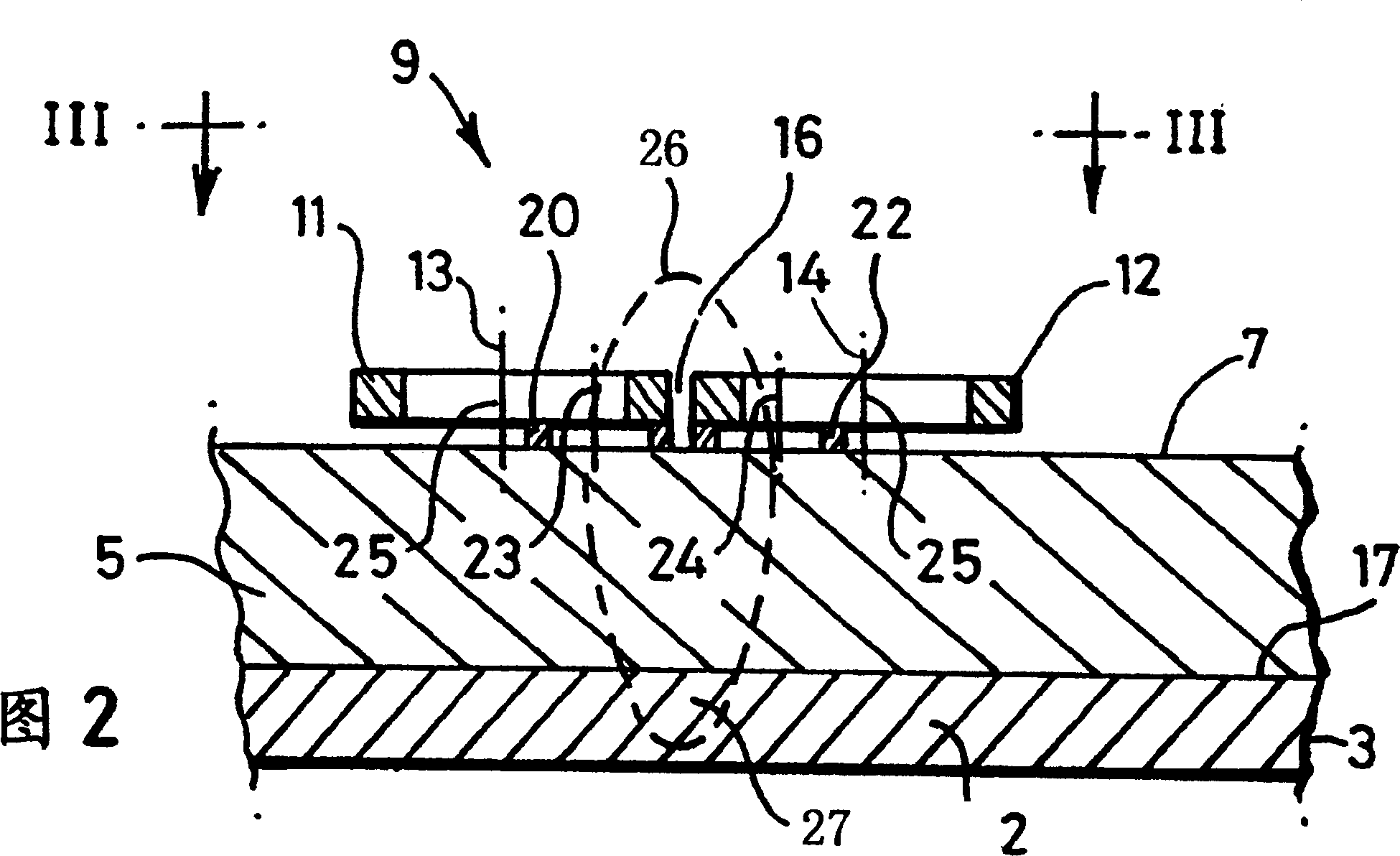

[0027] As shown in Figures 2 and 3, the device 9 for detecting objects made of conductive material includes a non-steady signal transmitter for generating a non-steady electromagnetic field in objects su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com