Solar cell panel inspecting apparatus, solar cell panel inspecting method, and solar cell panel manufacturing method

A technology for solar panels and inspection devices, which can be used in measuring devices, measuring electricity, photovoltaic power generation, etc., can solve problems such as residues, and achieve the effect of improving productivity and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

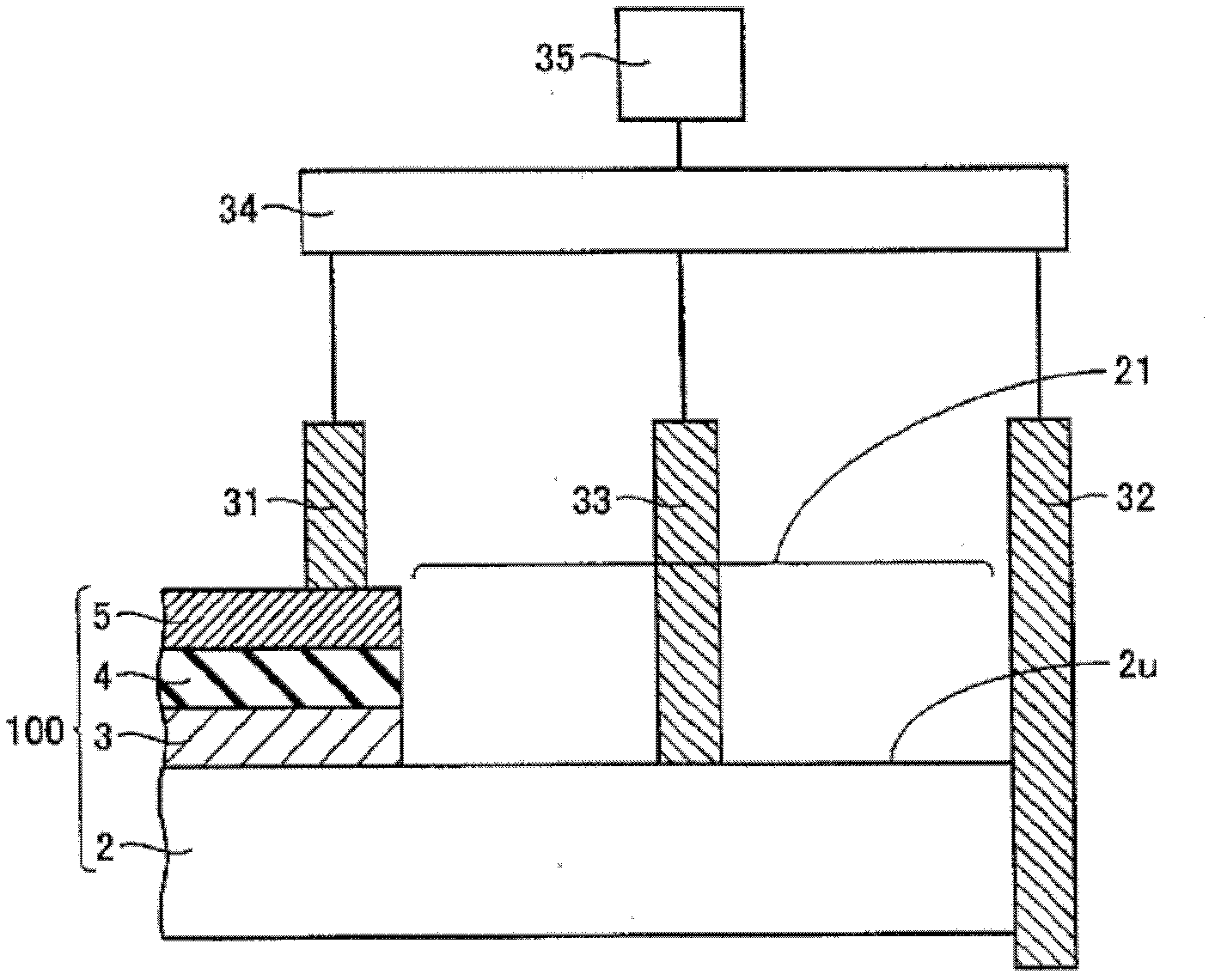

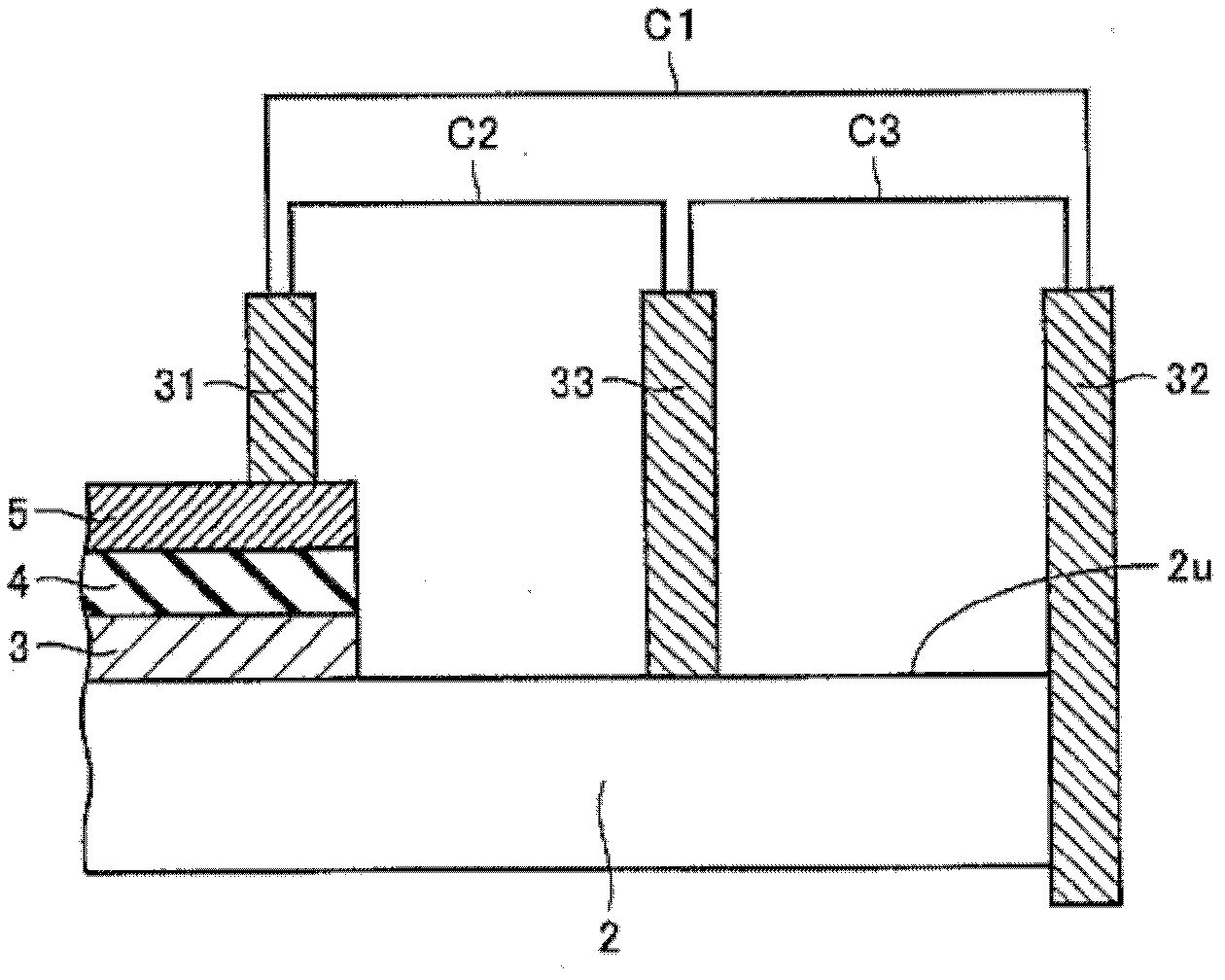

[0038] refer to figure 1 , figure 2 , the solar cell panel inspection device according to the first embodiment of the present invention will be described. The solar cell panel inspection device is used to inspect the insulation performance of the outer peripheral insulating region 21 of the solar cell panel 100. The solar cell panel 100 includes a transparent insulating substrate 2 having a main surface 2u and sequentially laminated on the main surface 2u of the transparent insulating substrate 2. The transparent electrode layer 3, the semiconductor photoelectric conversion layer 4, and the back electrode layer 5 have a peripheral insulating region 21 exposing the main surface 2u of the transparent insulating substrate 2 near the outer periphery of the transparent insulating substrate 2. The solar cell panel inspection device has: a first terminal 31 for abutting against the back electrode layer 5; a second terminal 32 for abutting against the vicinity of the outer peripher...

no. 2 approach

[0051] refer to Figure 14 , Figure 15 , a solar cell panel inspection device according to a second embodiment of the present invention will be described.

[0052] The solar cell panel inspection device of this embodiment is basically the same as the device described in the first embodiment, except that it is further capable of storing reference value data of current. and if Figure 14 Shown is a judging part 36 for comparing the current value detected by the current detecting part with the reference value after a predetermined time has elapsed since the voltage is applied by the voltage applying part, and according to the The comparison result determines whether to continue applying voltage to the two terminals. exist Figure 14 Among them, the reference value data of the voltage is held by the data holding unit 37 , and the judging unit 36 can read appropriate data from the data holding unit 37 .

[0053] Figure 15 A flowchart showing the operation of the solar pan...

no. 3 approach

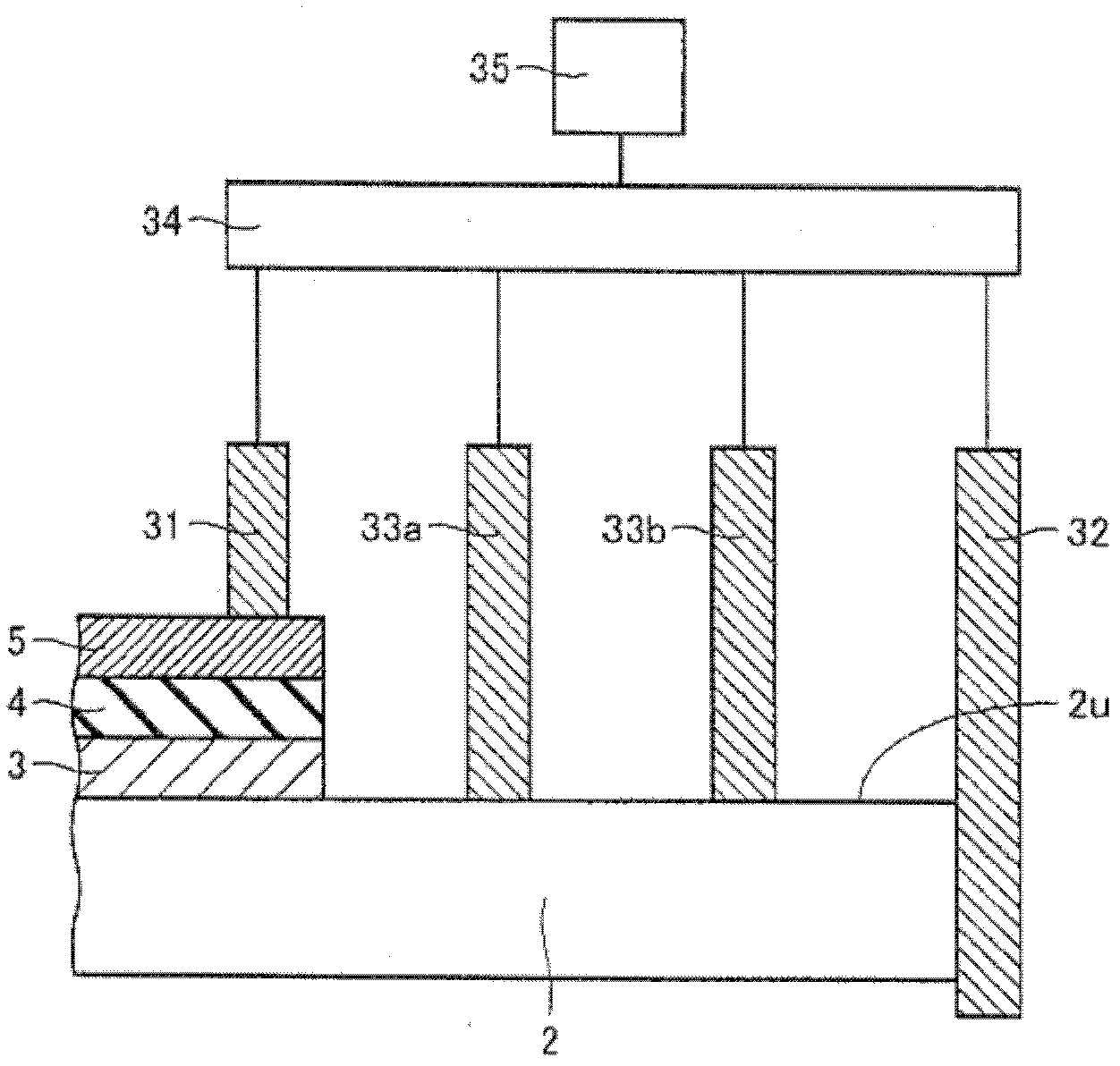

[0058] refer to Figure 16 , Figure 17 , a solar cell panel inspection device according to a third embodiment of the present invention will be described.

[0059] The solar cell panel inspection device of this embodiment is basically the same as the device described in the first embodiment except that Figure 16 , Figure 17 As shown, there is a third terminal switching mechanism 38, which is used to control the one or more terminals while maintaining the state that the first terminal 31 is in contact with the back electrode layer 5 and the second terminal 32 is in contact with the transparent insulating substrate 2. All or part of the third terminal is switched between a first state in contact with the outer peripheral insulating region 21 and a second state in which it does not contact the outer peripheral insulating region 21 , Figure 16 represents the first state, Figure 17 Indicates the second state. The third terminal switching mechanism 38 can be a one-way switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com