Single-film concave-convex chain clipped applying bag making machine

A bag making machine and zipper technology, applied in container manufacturing machinery, box making operations, rigid/semi-rigid container manufacturing, etc., can solve the problems of small specification range, lower production efficiency, and inability to print in multiple colors, and meet the specifications Wider range and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

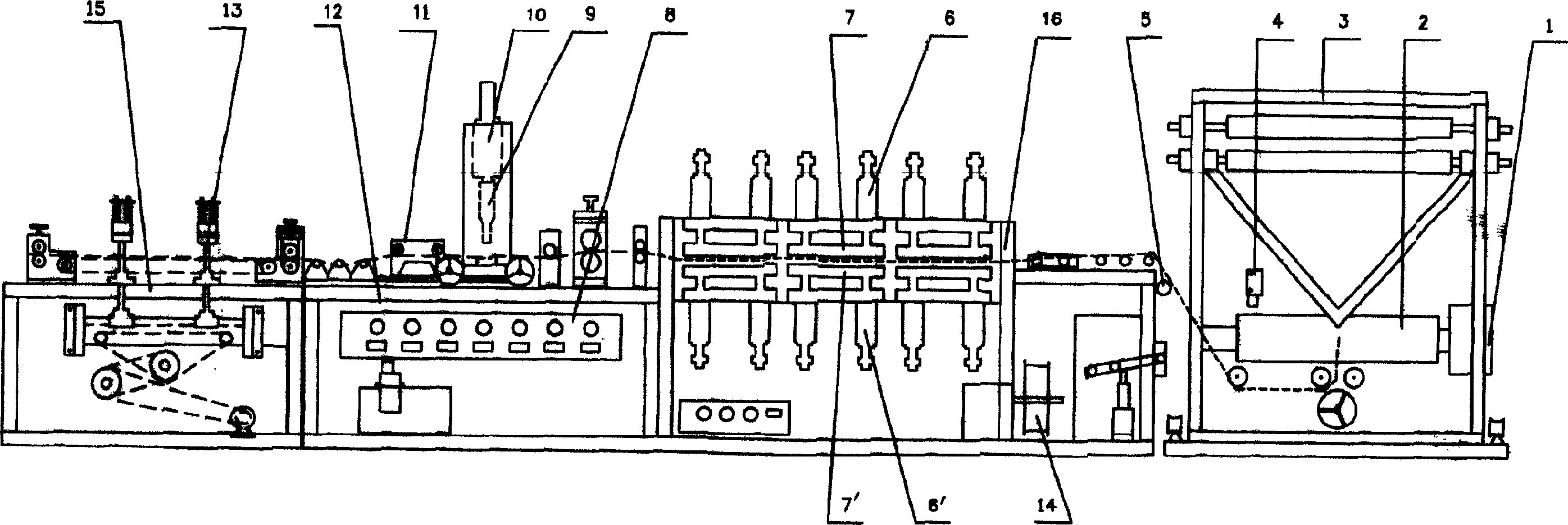

[0012] The accompanying drawings show the structure of the present invention and its embodiments, and the related details of the embodiments are further described below with reference to the accompanying drawings. The single-film concave-convex clip chain lamination bag making machine includes an automatic film folding mechanism 3, a clip chain feeding mechanism, a clip chain laminating mechanism 16, a bag corner gluing mechanism 12 and a sealing and cutting mechanism 15. The clip chain discharging mechanism The mechanism is placed on the edge of the clip chain bonding mechanism 16 (not shown in the figure). The automatic film folding mechanism 3 is to fold the flexible packaging film into semi-finished bags. and an automatic deviation corrector (not shown in the figure), the magnetic powder clutch 1 is used to control the tension of the film, so that the film reel rotates according to the required length of the ziplock bag, and the reel will not rotate due to inertia, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com