Electron gun

An electron gun and electron technology, applied in the fields of electron gun, exposure and drawing technology, can solve problems such as the difficulty of the electron beam exposure device, and achieve the effect of eliminating the electrification problem and the beam position variation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

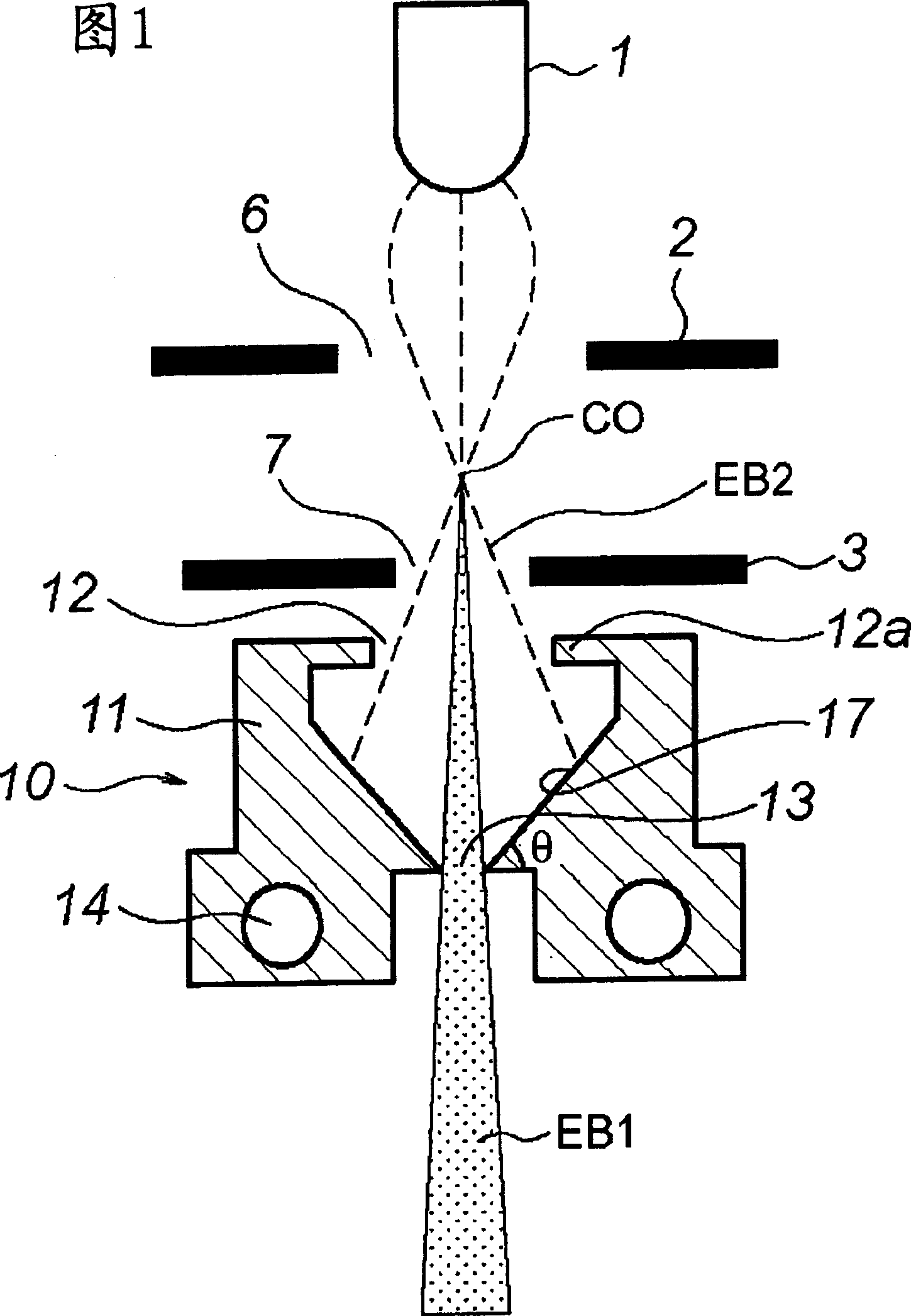

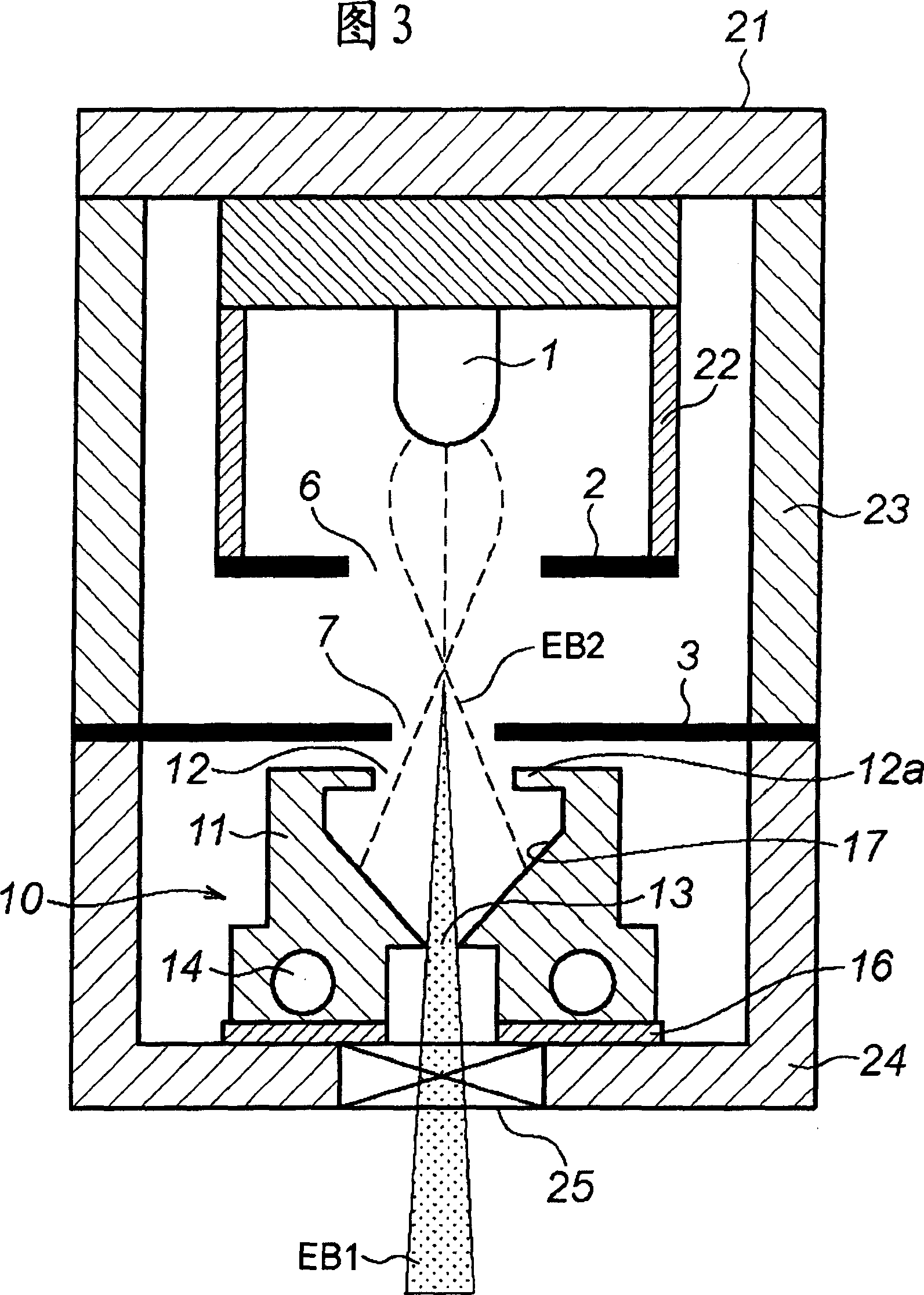

[0032] Hereinafter, embodiments of an electron gun and an exposure apparatus equipped with the electron gun according to the present invention will be described in detail with reference to the accompanying drawings.

[0033] Also, the present invention, as the electron beam exposure apparatus exemplified in this embodiment, can also be similarly applied to: a device that irradiates a mask with an electron beam and projects the mask pattern onto a wafer for exposure; It is self-evident that there is a device that directly draws on a wafer, or a device that draws a mask pattern on a reticle with an electron beam, and the like.

[0034] Figure 7 It is an example of the multi-electron beam method. The electron beam EB emitted from the single electron source 101 is collimated into parallel light by the converging lens 102. After the electron beam is divided into multiple electron beams by the aperture and splitter 103, the aberration is corrected The multi-lens 104 is used to cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com