Technique for recycling waste fluid containing urea

A waste liquid recovery and urea technology, applied in heating water/sewage treatment, degassed water/sewage treatment, chilled water/sewage treatment, etc., can solve the problems of high energy consumption, excessive discharge, high operating costs, etc., and achieve equipment investment The effect of reducing, eliminating pollution and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

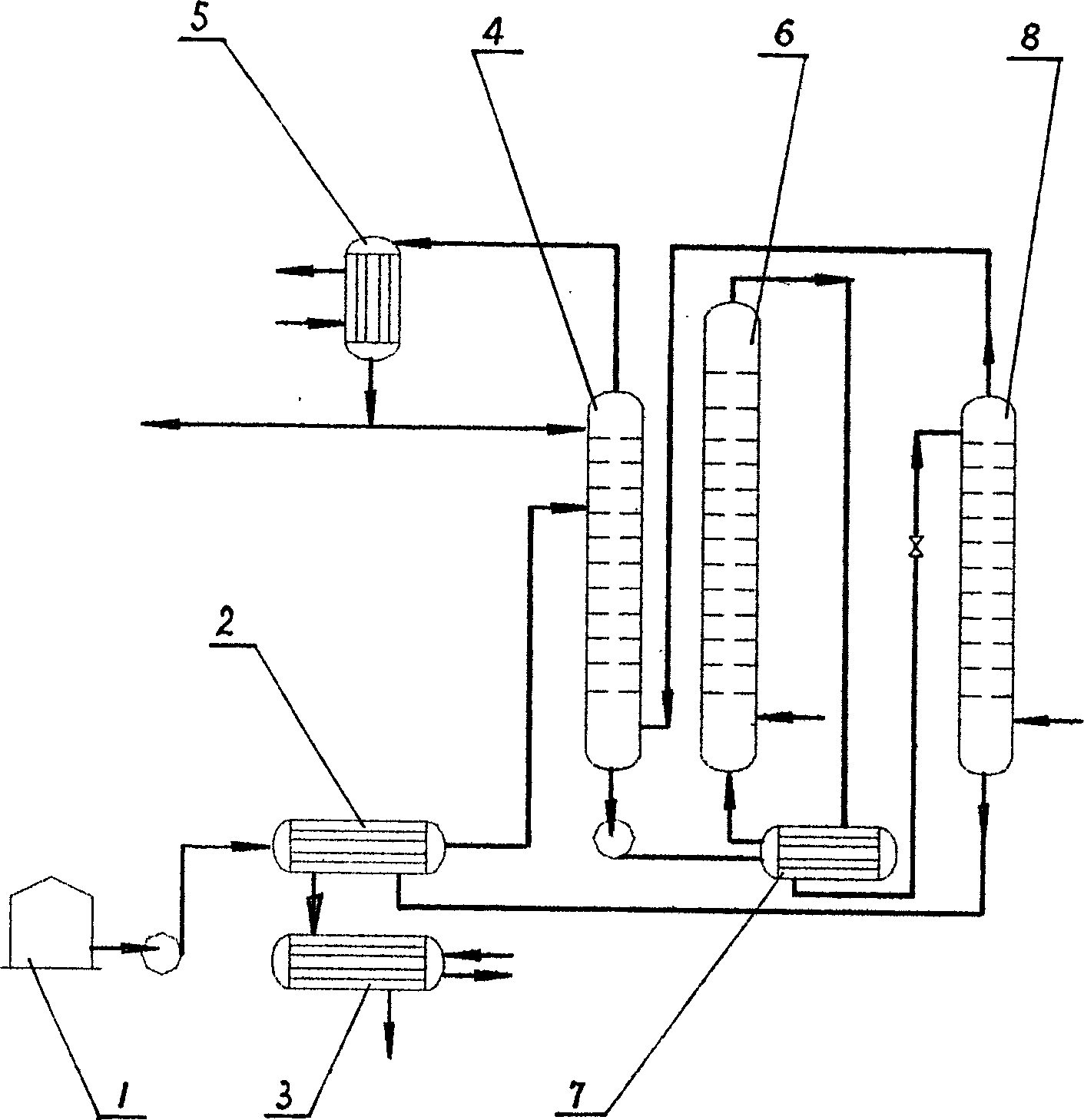

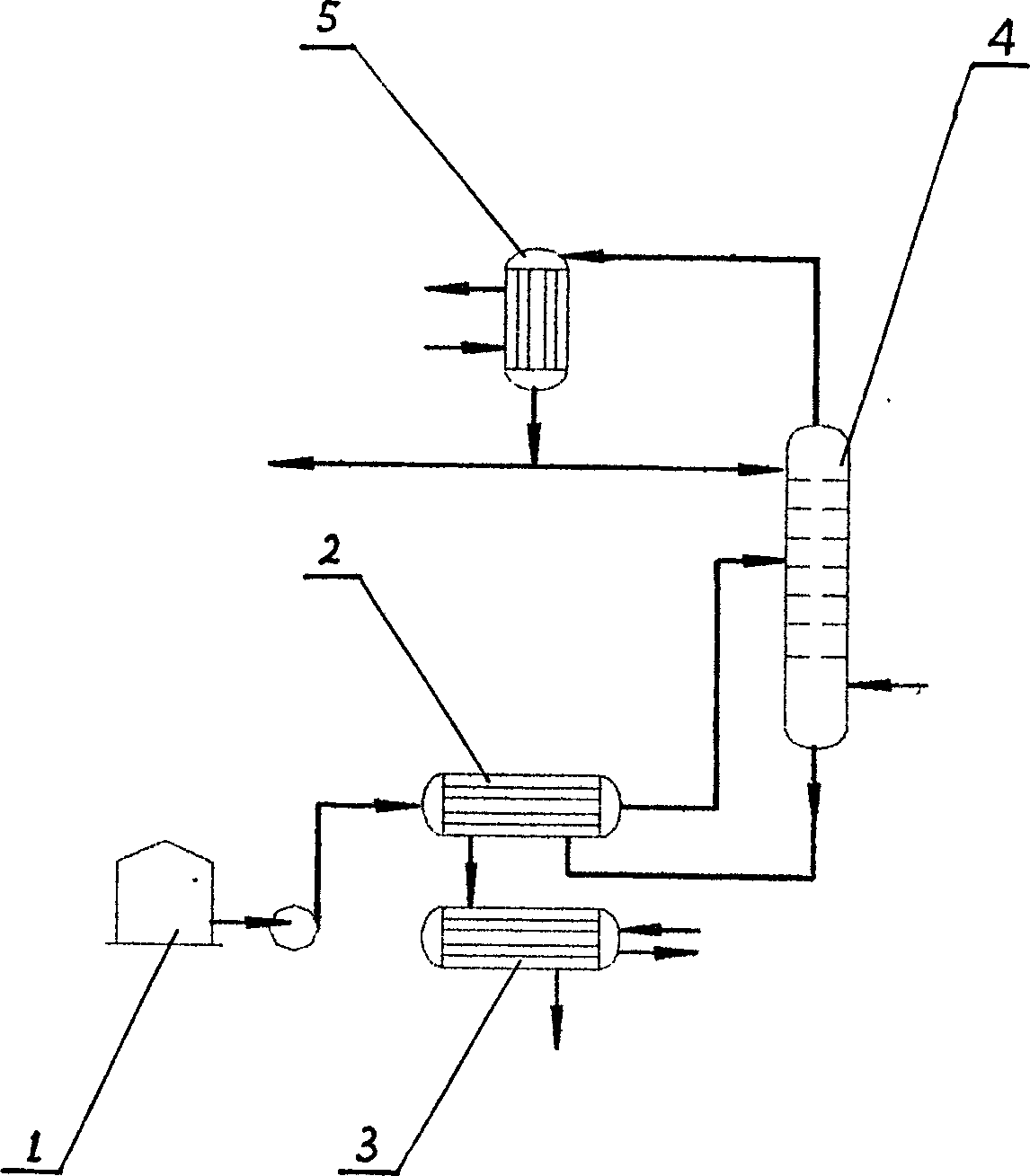

[0029] Embodiment 1: as Figure 4 As shown, first the urea process contains urea, NH 3 and CO 2 The waste liquid from the condensate tank 1 is preheated by the heat exchanger 2, and then sent to the desorption tower 4, and the NH in the urea-containing waste liquid is indirectly heated by steam 3 and CO 2 Desorption; then containing NH 3 and CO 2 The desorbed gas is condensed through the reflux condenser 5, and the condensate is divided into two paths, one path is used as tower top reflux, and the other path returns to the urea production system; the urea waste liquid discharged from the desorption tower 4 is divided into two paths, and one path passes through the reboiler 9 Heating is returned to the bottom of the desorption tower 4, and the other way is sent to the evaporator 10, and the medium-pressure steam of 2000Kpa is used to control the evaporation and concentration under the pressure of 300Kpa. When the concentration of urea is 40%, the obtained urea concentrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com