Method of preparing fibre powder body of Nano alumina in high purity

A technology of nano-alumina and fiber powder, which is applied in the field of preparation of high-purity nano-alumina fiber powder by chemical gas-solid phase reaction method, can solve problems such as pollution, and achieve broad application prospects, high yield, and strong adsorption force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

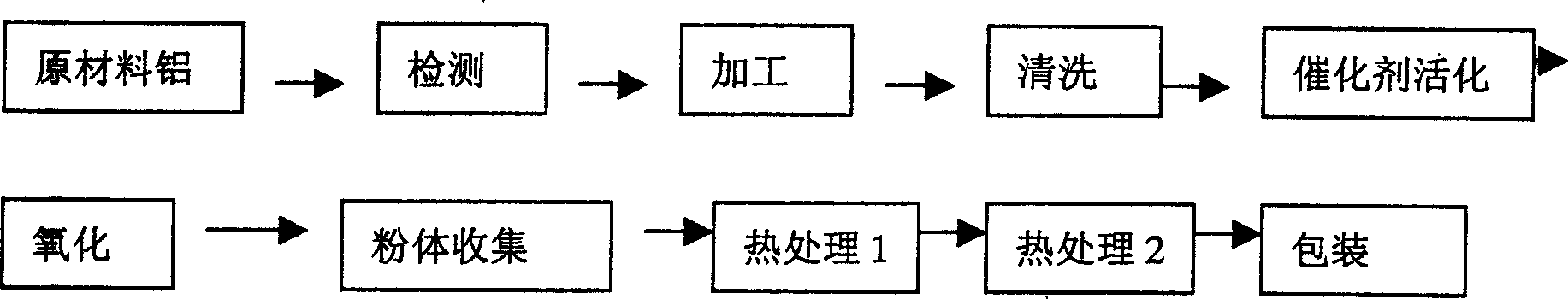

Method used

Image

Examples

Embodiment Construction

[0021] Dissolve the HV-1 catalyst in distilled water, add mineral acid and heat slightly, but the temperature should not exceed 40°C to promote its dissolution. The concentration of catalyst HV-1 is between 3% and 8%. When it is lower than 3%, the catalyst should be replenished in time. The catalyst is produced by Nanjing Nanda Yurun Nano Technology Engineering Center.

[0022] The pure aluminum is soaked in the catalyst solution for 1-30 minutes for activation treatment, and after the aluminum is taken out, the surface is rinsed with distilled water to wash off surface impurities. Then place the aluminum on the blowing outlet, and blow air to the metal aluminum through the air compressor. It is also possible to control the temperature of the blowing gas to 35-40°C. The higher the air blowing temperature, the shorter the time, usually 10-60 minutes. Then leave it for 1-10 hours, at this time, the surface of the aluminum reacts with the oxygen in the air to form nano-alumina ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com