Fuel oil environmental protection oil saving device

A fuel-saving and environmentally friendly technology, applied in the direction of machines/engines, combustion air/combustion-air treatment, engine components, etc., can solve the problems of insignificant fuel-saving effect, unstable power and work, high production costs, etc., to achieve production costs Low cost, good purification effect, remarkable fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

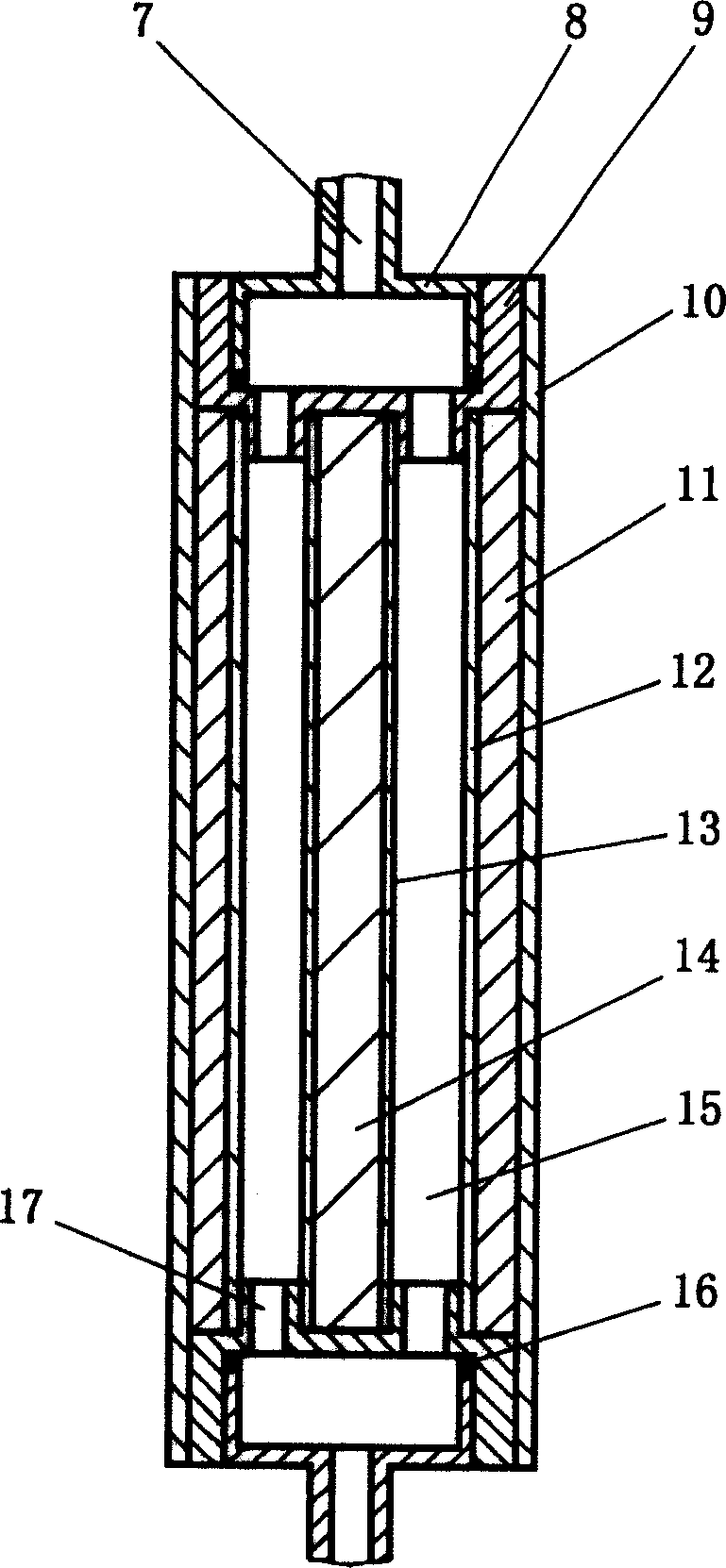

[0017] Refer to attached figure 1 , a kind of fuel environmental protection fuel economizer, it comprises two oil circuit joints 2, shell 3, catalytic tube 4 and inner liner 5, wherein two oil circuit joints 2 are respectively fixed on the two ends of catalytic tube 4, inner liner 5 Set in the inner hole of the catalytic tube 4, the outer shell 3 is set on the outer surface of the catalytic tube 4, the inner cavity 6 of the fuel-friendly economizer is composed of the inner hole of the inner bushing 5, and the oil hole 1 on the oil joint 2 is connected with the The inner cavity 6 communicates.

[0018] in:

[0019] Oil joint 2 is made of copper; shell 3 and inner bushing 5 are made of high temperature resistant plastic.

[0020] The process of making catalytic tube 4 is:

[0021] 100 kilograms of zirconium, 30 kilograms of carbon, 30 kilograms of silicon, 25 kilograms of copper, 10 kilograms of titanium, 10 kilograms of chromium, 5 kilograms of cobalt, 20 kilograms of clay c...

Embodiment 2

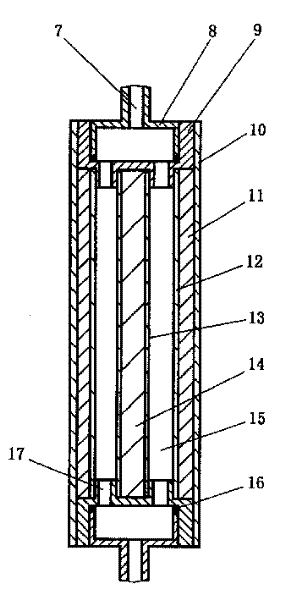

[0023] Refer to attached figure 2 , a kind of fuel environmental protection fuel economizer, it comprises two oil circuit joints 8, two end caps 9, shell 10, catalytic tube 11, inner bushing 12, outer bushing 13, catalytic rod 14; Wherein outer bushing 13 is set On the outer surface of the catalytic rod 14; the inner liner 12 is arranged in the inner hole of the catalytic tube 11; the shell 10 is arranged on the outer surface of the catalytic tube 11; an oil joint 8 and an end cover 9 are fixed together, There is a sealing ring 16 between the oil joint 8 and the end cover 9; the two end covers 9 are respectively fixed on the two ends of the catalytic tube 11 and the catalytic rod 14; The gap between the sleeves 13 is formed, and the oil hole 7 on the oil joint 8 communicates with the oil hole 17 on the end cover 9 and the inner cavity 15 .

[0024] in:

[0025] Oil joint 8 and end cap 9 are made of copper; shell 10, inner bushing 12 and outer bushing 13 are made of high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com