Method of pelletizing high temperature alloy liquid

A superalloy and liquid technology, applied in the field of superalloy liquid granulation, can solve the problems of slow granulation speed, energy consumption, rising cost, etc., and achieve the effects of accelerated granulation speed, energy saving and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

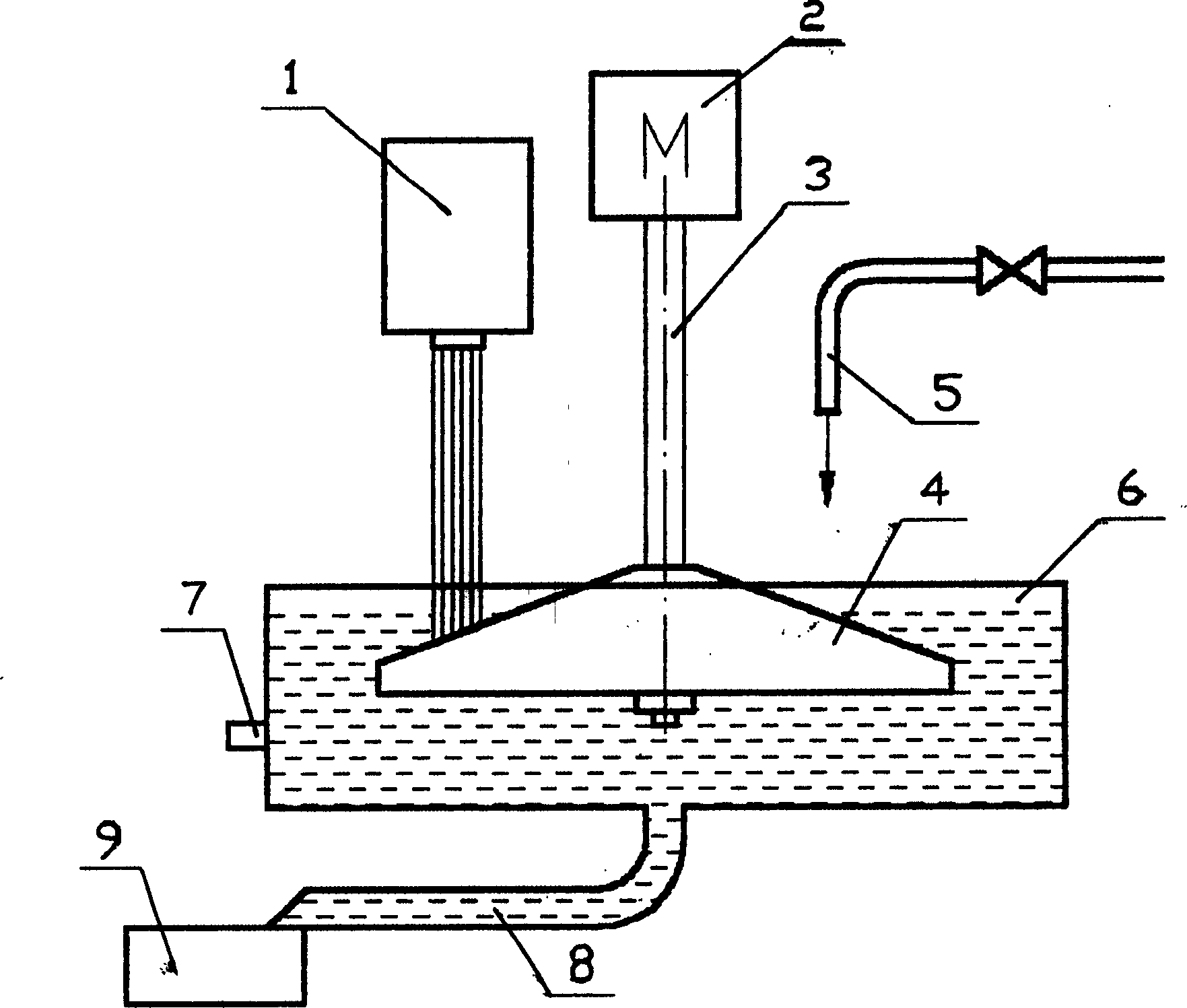

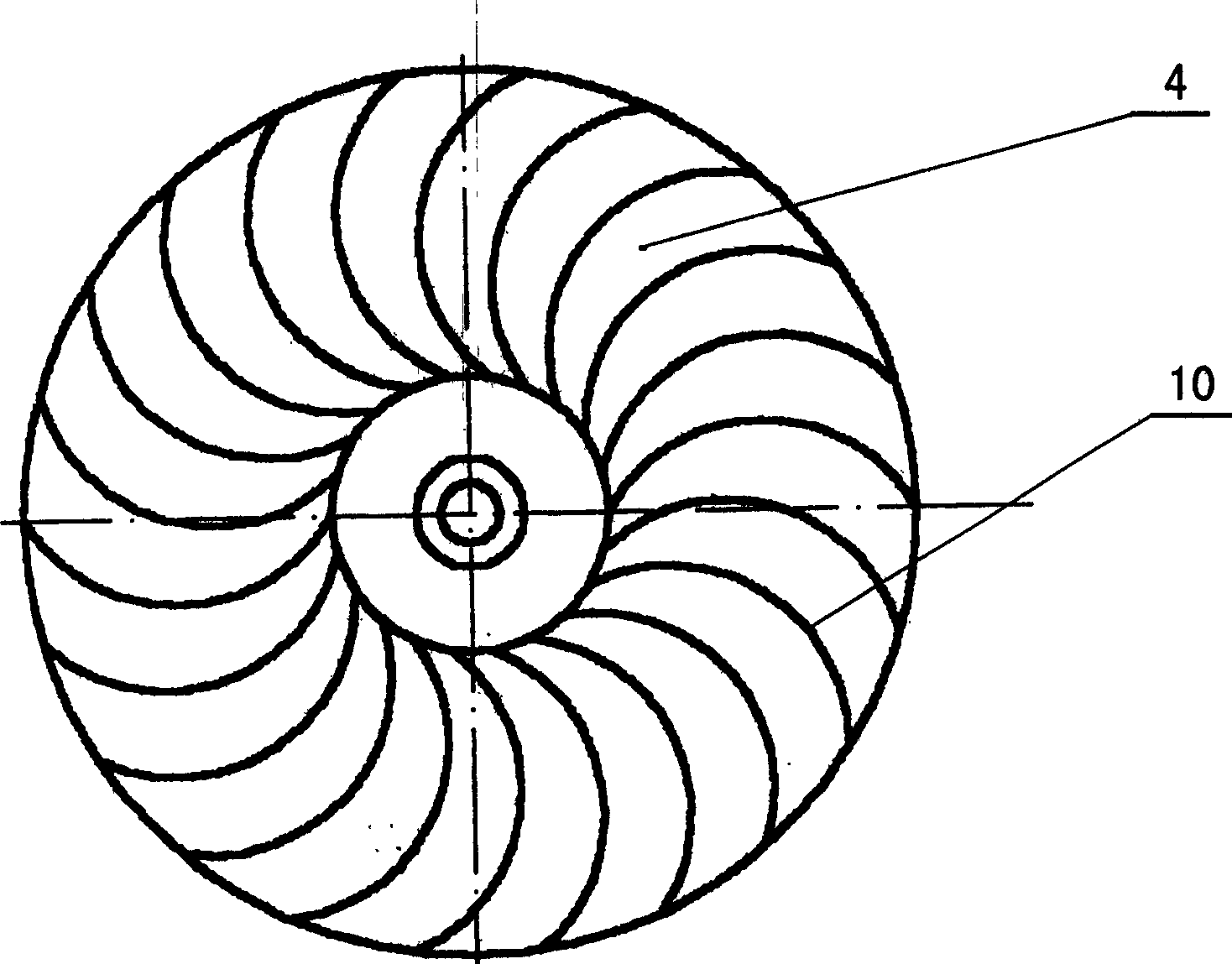

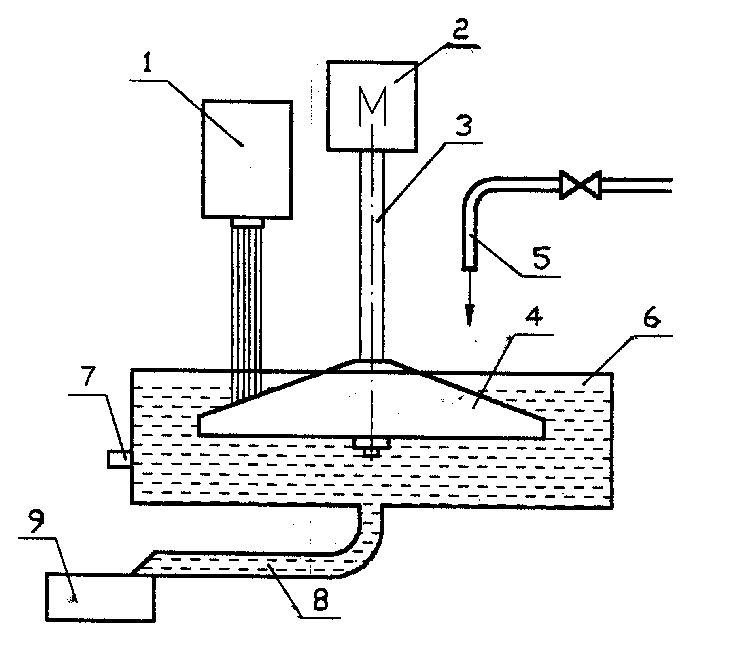

[0010] See figure 1 , pour the alloy liquid into the granulation hopper 1, the alloy liquid drips from the rectangular outlet onto the rotary turntable 4, the temperature when dripping is 1000°C, the rotary turntable 4 is circular, and there is an involute groove on it 10. The groove width is 2mm-10mm, the groove depth is 0.5mm-2mm. The rotary turntable 4 is driven by the shaft 3 under the control of the speed-regulating motor 2 to rotate at a speed of 75 rpm to 200 rpm. It is granulated and formed through the involute groove 10 on it, and the size of the alloy particles is controlled by the speed of the rotary turntable 4, the size of the involute shallow groove, the height of the granulation hopper 1 and the size of the rectangular outlet of the granulation hopper. The alloy particles fall into the water quenching tank 6, and after quenching with cooling water, the product is obtained from the feeding port 8 to the finished product tank 9. The specific parameters are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com