Switch device of high-voltage metal steaming discharge light and front light device of vehicle

A metal vapor and discharge lamp technology, which is applied in the field of vehicle headlamp devices and high-pressure metal vapor discharge lamp turn-on devices, can solve the problems of fluctuation solutions, and the characteristics of high-pressure metal vapor discharge lamps are not provided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

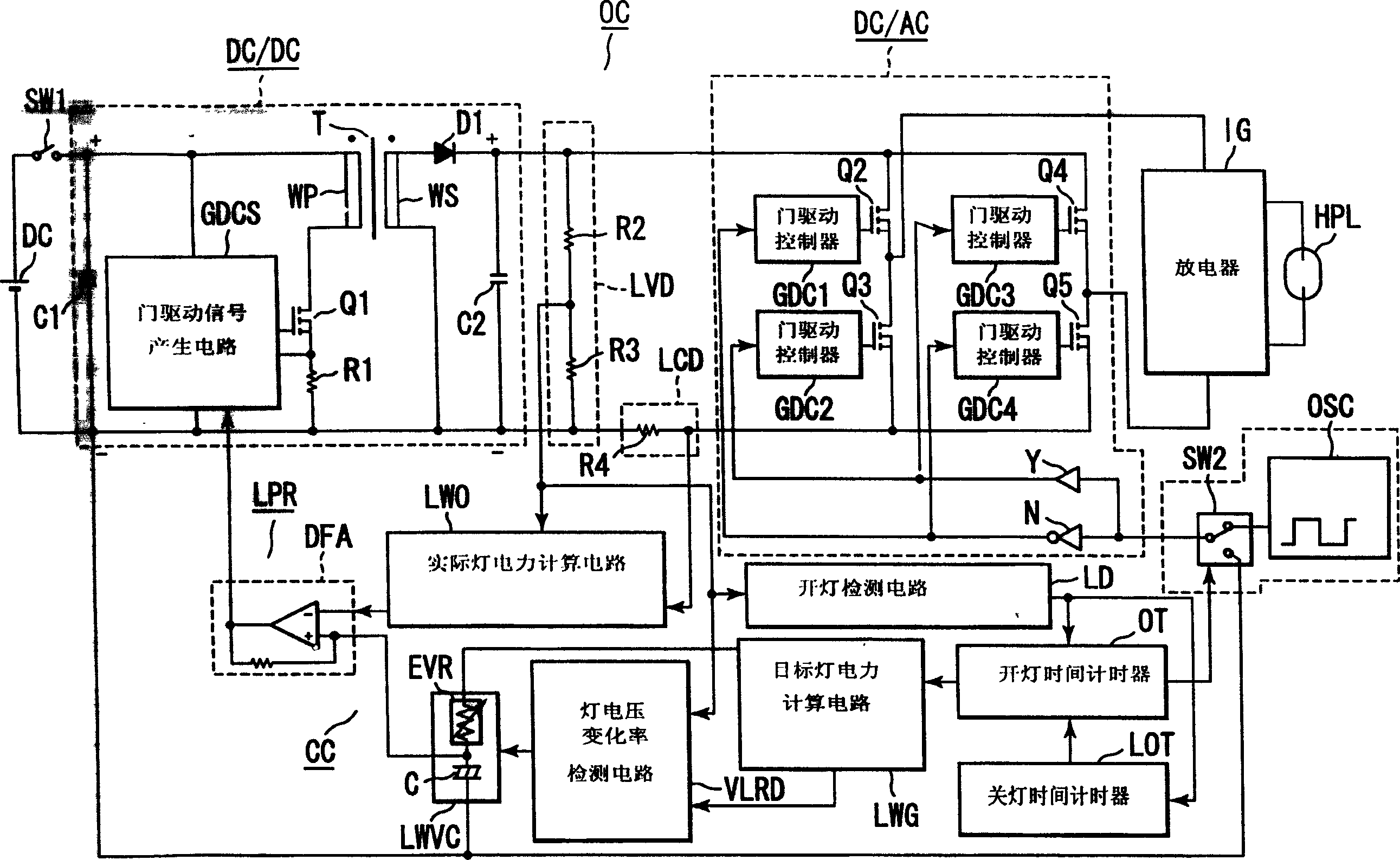

[0107] This embodiment is a high-pressure metal vapor discharge lamp lighting device used for lighting a mercury-free lamp in a headlight device for an automobile. figure 1 Among them, DC is a direct current power supply, SW1 is a power switch, OC is a lamp circuit, CC is a controller, IG is a discharger, and HPL is a high-pressure metal vapor discharge lamp. Next, each constituent element will be described.

[0108] The DC power supply DC is composed of a storage battery with a DC voltage of 12V.

[0109] The power switch SW1 is connected in series between the direct current power supply DC and the lighting circuit OC described later, and manages the flickering of the high-pressure discharge lamp HDL.

[0110] About the light circuit OC

[0111] The light-on circuit OC is composed of a switching voltage regulator DC / DC and a converter DC / AC.

[0112] About Switching Regulator DC / DC

[0113] Switching voltage regulator DC / DC is mainly composed of output transformer T, con...

Embodiment

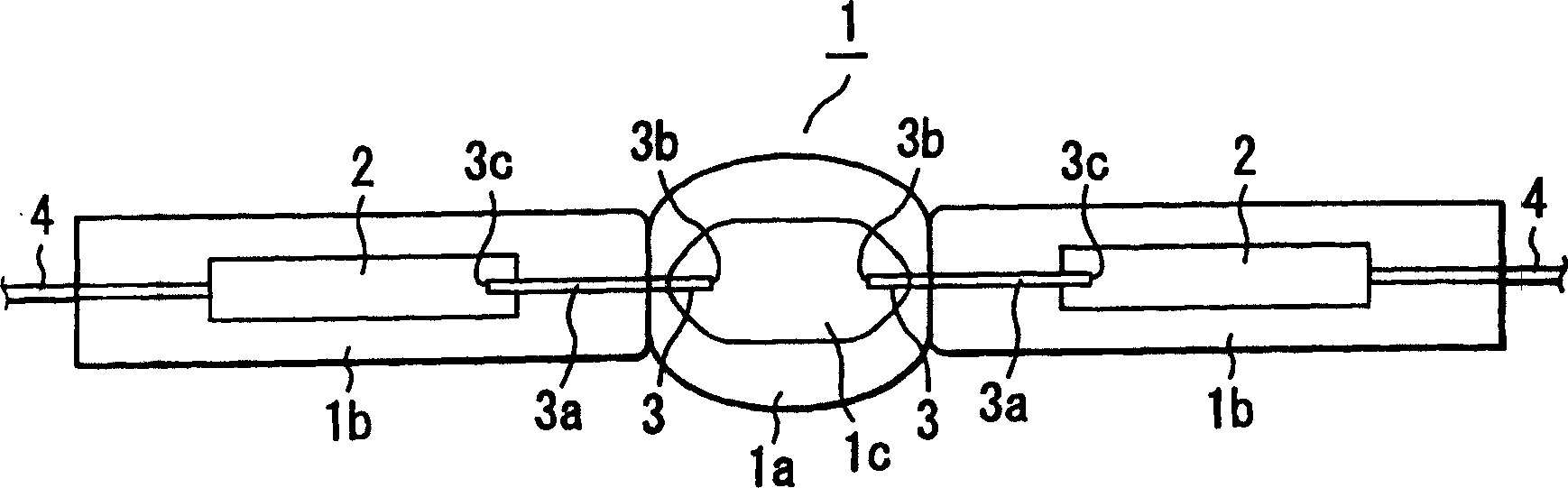

[0157] Airtight container 1 : made of quartz glass, with an outer diameter of 6 mm, an inner diameter of 2.7 mm, and a surrounding portion length of 7.0 mm.

[0158] Electrode 3: made of tungsten, shaft diameter 0.35 mm, radius of curved surface at the tip that becomes the starting point of arc 0.175 mm, distance between electrodes 4.2 mm, protruding length 1.4 mm.

[0159] Discharge media

[0160] Metal halide: ScI 3 -NaI-ZnI 2 =0.4mg

[0161] Xenon: 10 atmospheres at 25°C.

[0162] Electrical characteristics: Lamp power 35W, lamp voltage 42V (when any item is stable).

[0163] About circuit work

[0164] Regarding circuit work at low temperature start

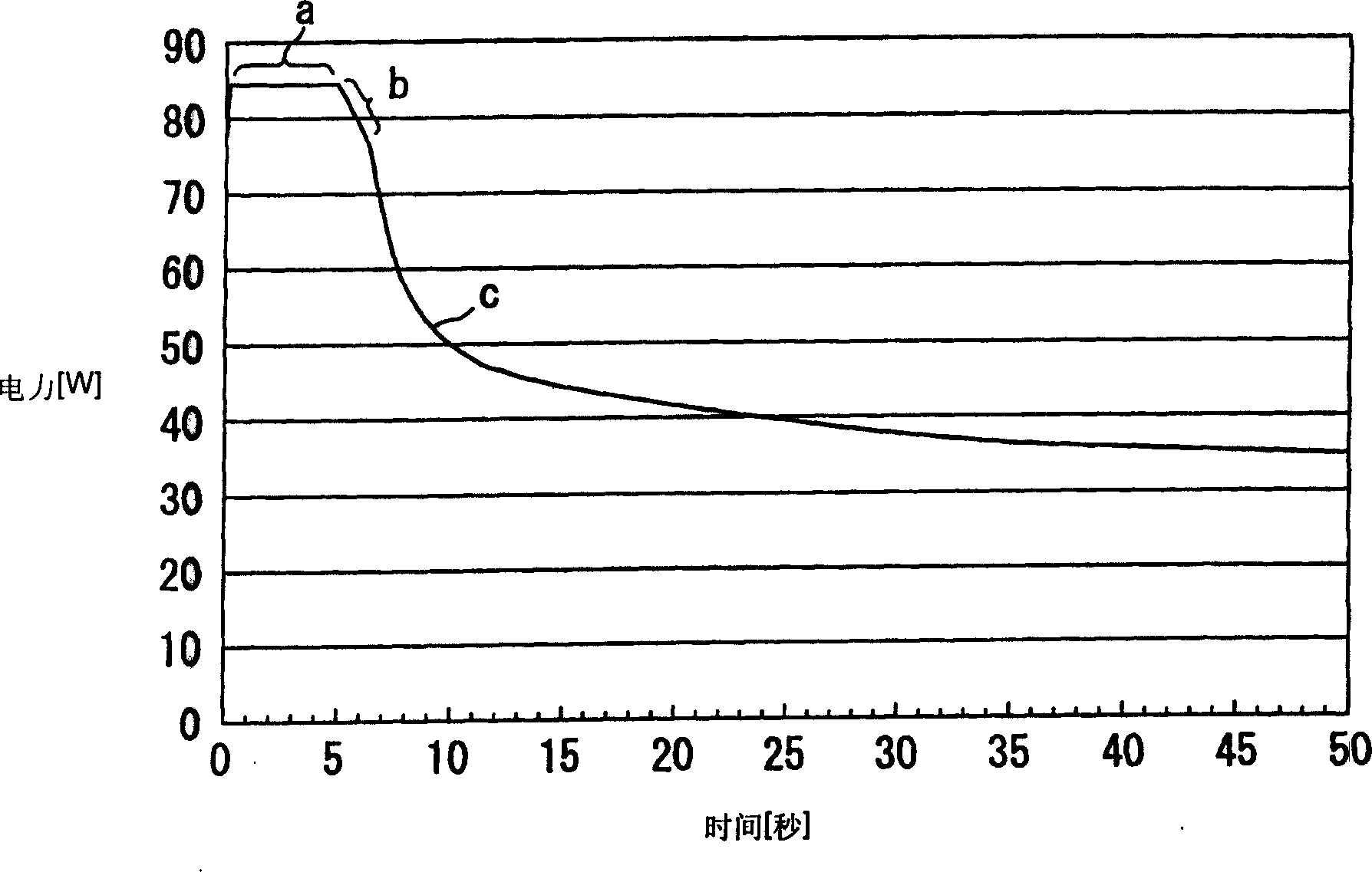

[0165] When starting at a low temperature below room temperature, since a certain period of time has elapsed since the last time the lamp was turned off, the high-pressure metal vapor discharge lamp HPL is cooled to at least room temperature. In this state, when the power switch SW1 is closed, the switching regulator D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com