Integraph column bearing unit

A technology of integrating columns and supporting parts, which is applied in the field of integrating columns, can solve the problems of limited heat, high conduction coefficient, high contact thermal resistance, and low conduction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

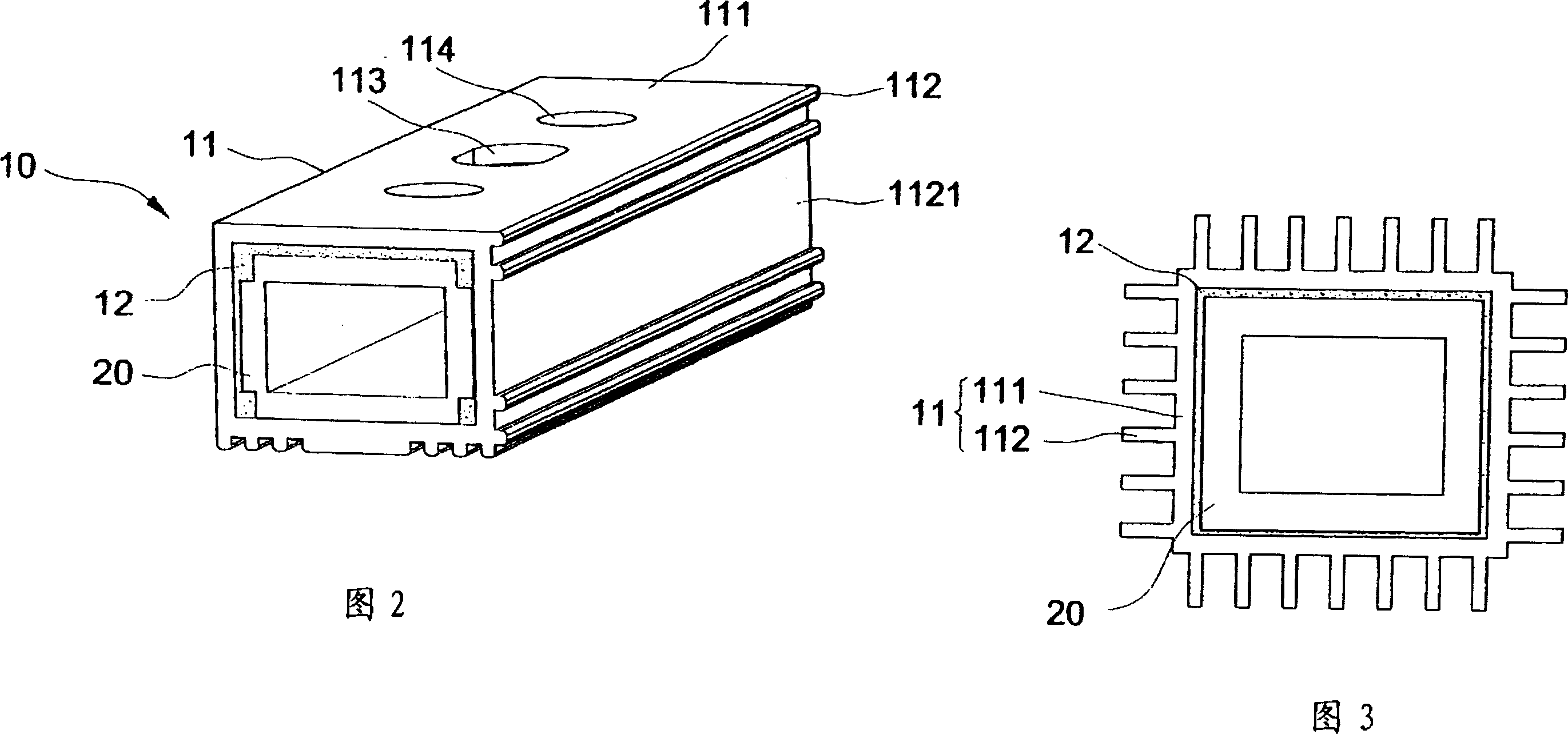

[0032] Relevant present invention is to achieve the above-mentioned purpose, and adopts technical means and all the other effects, with following preferred embodiment, and cooperates accompanying drawing to illustrate as follows:

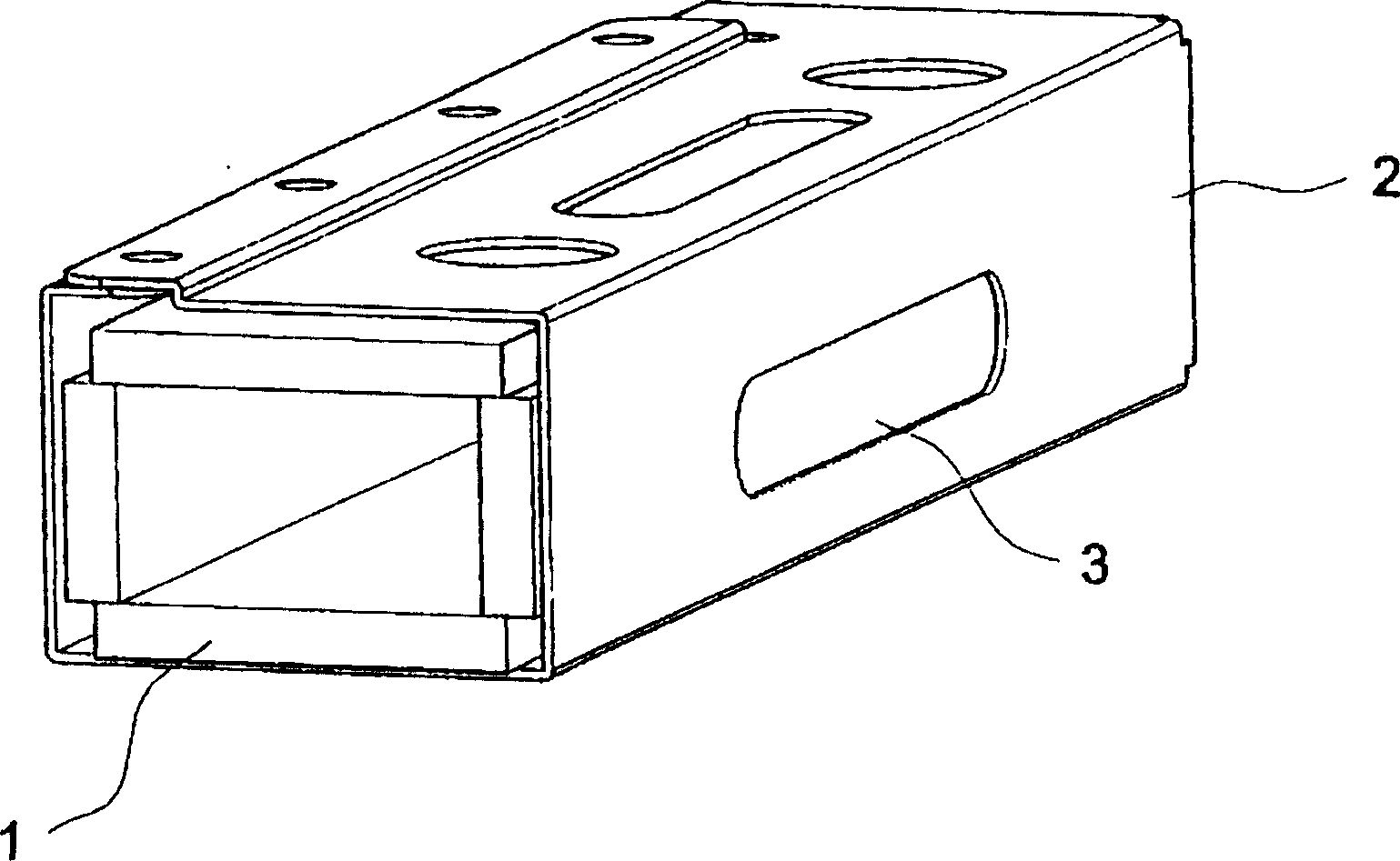

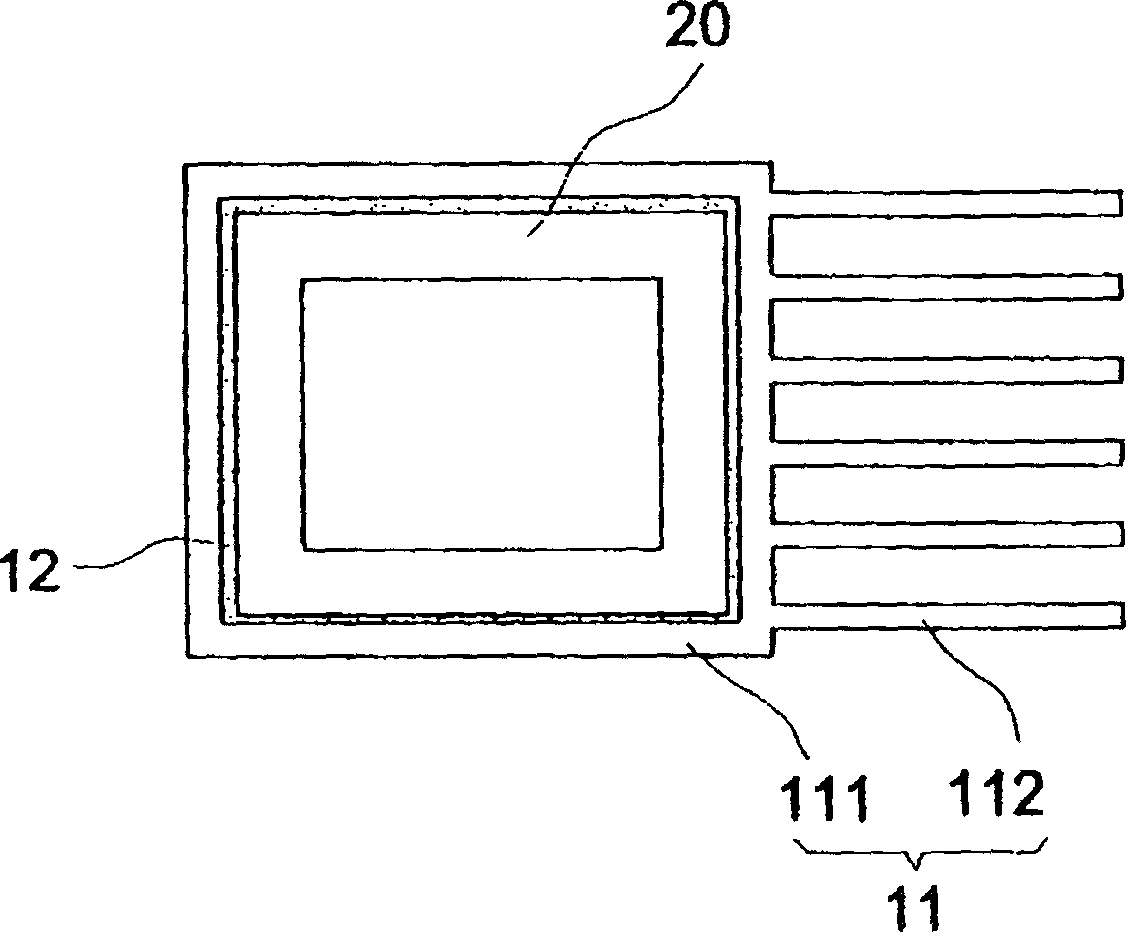

[0033] Please refer to Fig. 2, the integrating column supporting device 10 of the present invention comprises a supporting part 11, the supporting part 11 is arranged on the outside of an integrating column 20, and the space between the supporting part 11 and the integrating column 20 is filled with Heat-conducting substance 12; the shape of the supporting member 11 can be set according to the space and the shape of the integrating column 20, and the present embodiment cooperates with the integrating column 20 and is set as a hollow cylinder, and the hollow part is accommodated by the integrating column 20. Part 11 is made up of a heat dissipation substrate 111 and a plurality of fins 112. The heat dissipation substrate 111 is made of a material with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com