a printed circuit board

A printed circuit board, copper plate technology, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problem of heat dissipation and heat accumulation of printed circuit board, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

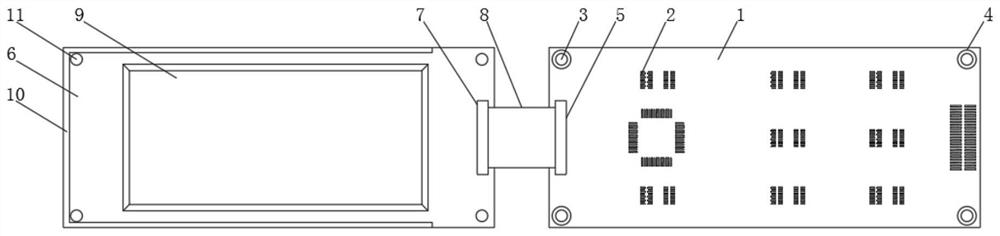

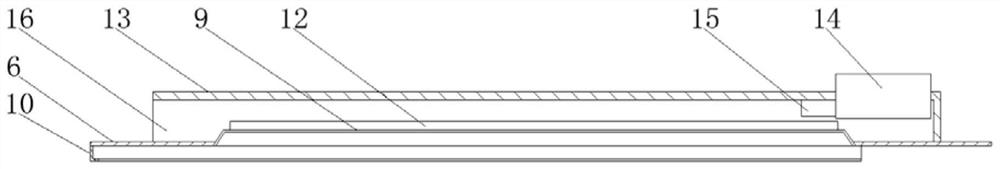

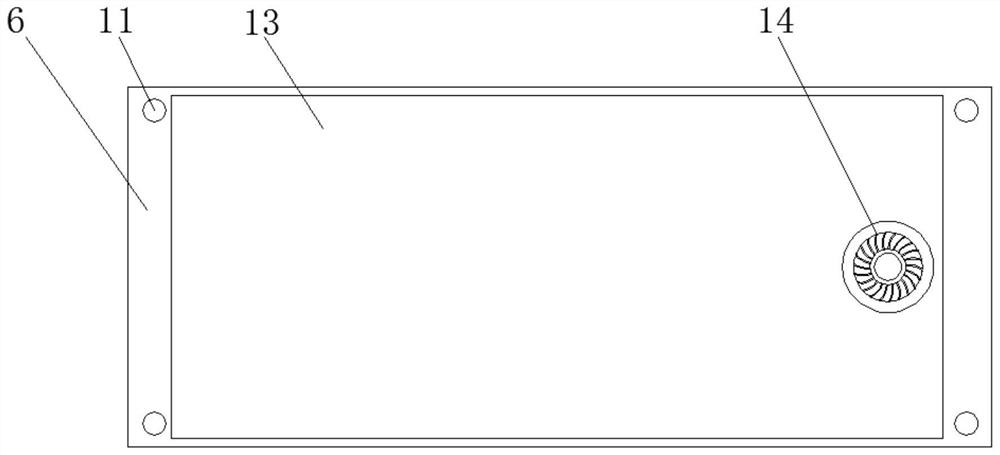

[0028] Such as Figure 1-5 As shown, the embodiment of the present invention provides a printed circuit board, including a printed circuit board body 1, a plurality of first conductive contacts 2 are uniformly arranged on the outer surface of the printed circuit board body 1, and one side of the outer surface of the printed circuit board body 1 The first cable connector 5 is fixedly connected, and the first cable connector 5 is embedded with a conductive cable 8. The side of the conductive cable 8 away from the printed circuit board body 1 is provided with a fixed protective cover 6, and the bottom of the fixed protective cover 6 The side close to the conductive cable 8 is fixedly connected with the second cable connector 7, and the second cable connector 7 is embedded with the conductive cable 8, and the bottom edge of the fixed protective cover 6 is away from the second cable. The positions of the joints 7 are all provided with positioning slide rails 10, the middle position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com