Installation device for equipment having cooling demand

A technology for installing devices and equipment, which is applied in the direction of structural components of electrical equipment, modification of power electronics, cooling/ventilation/heating renovation, etc. Low manufacturing cost, simple manufacturing process, good dustproof and waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

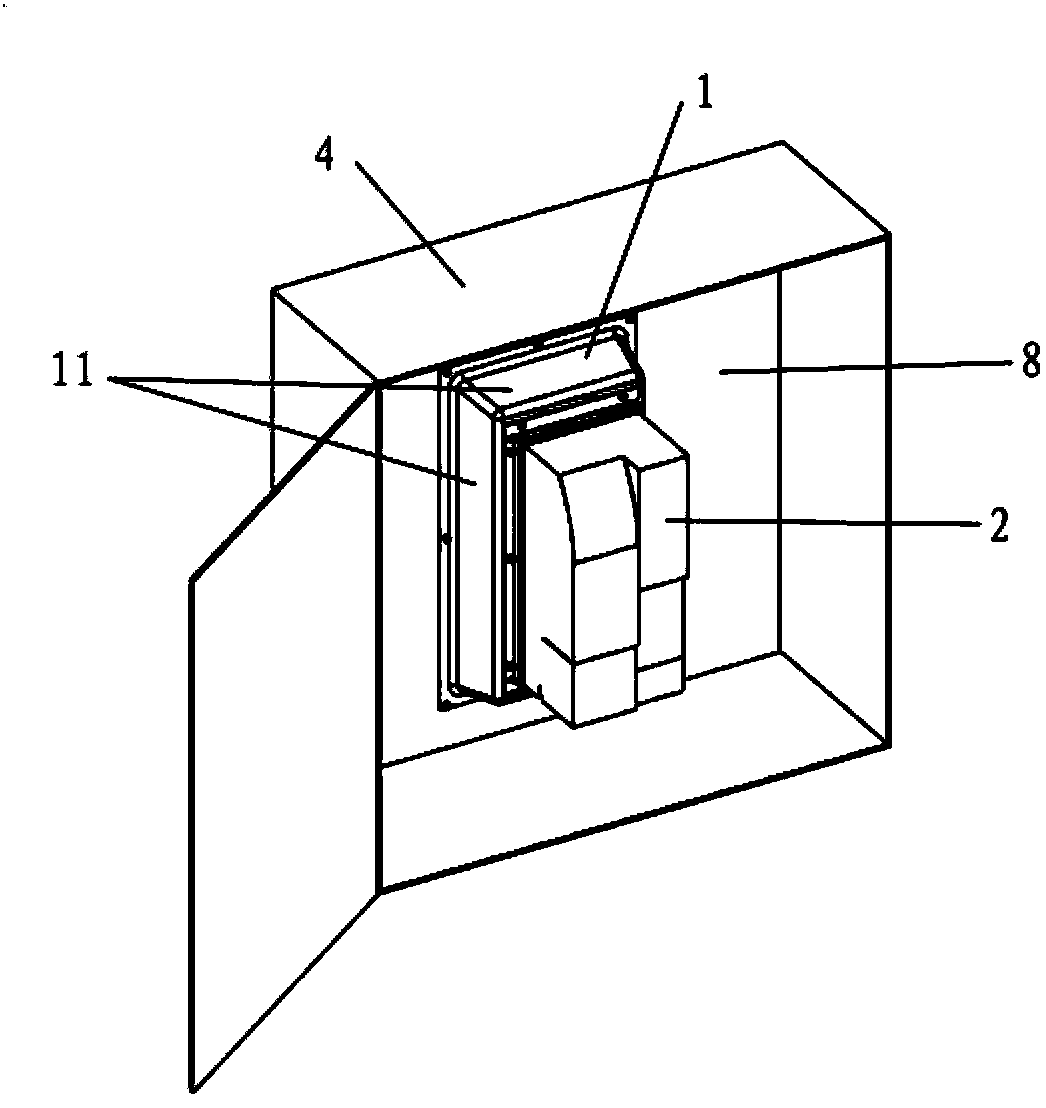

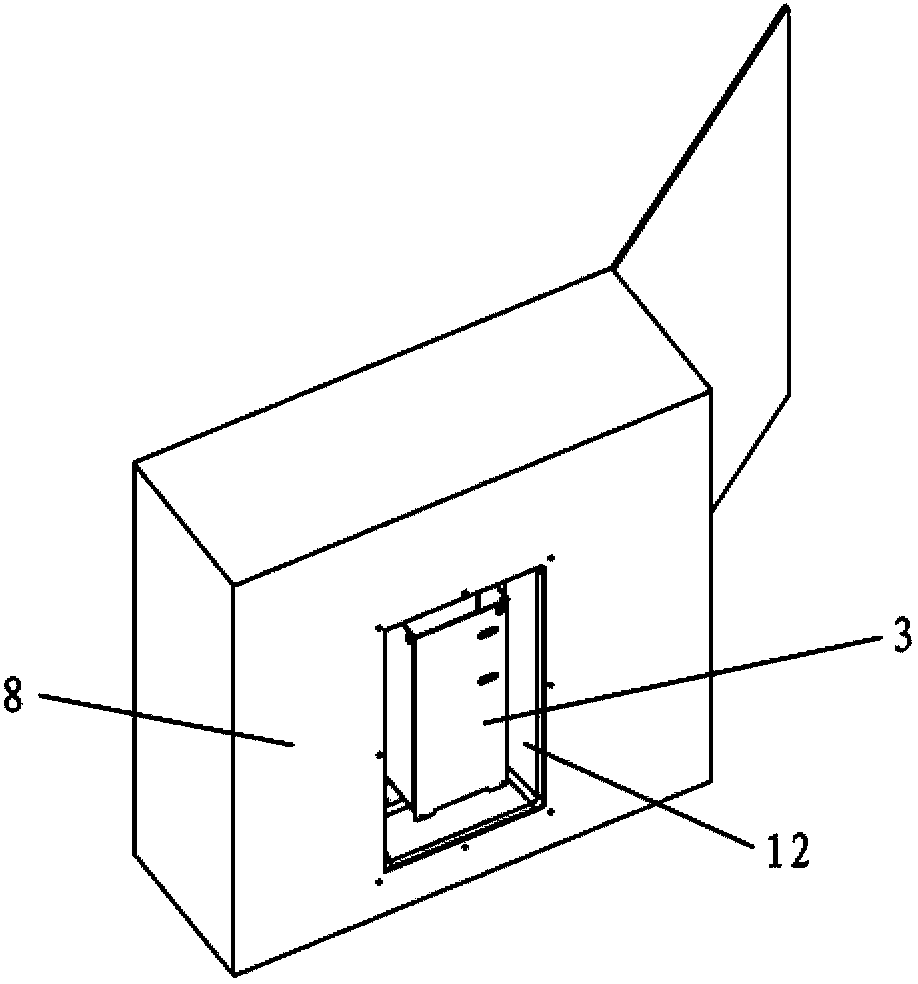

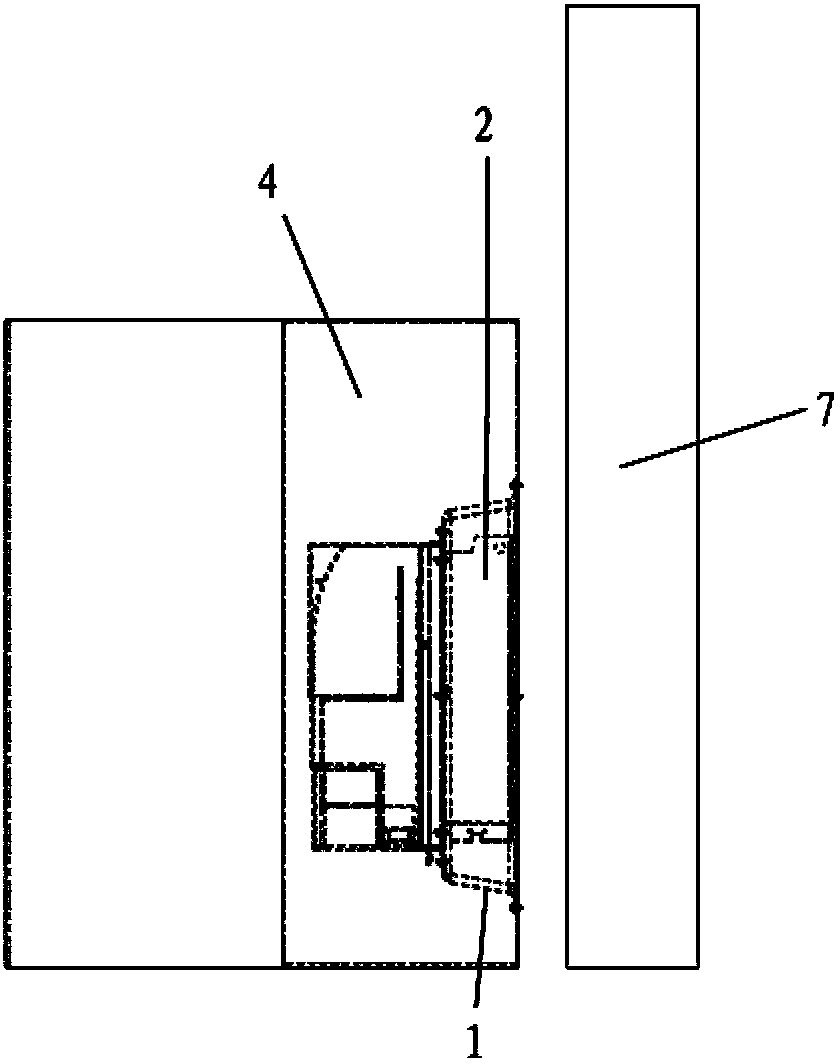

[0043] The following will be combined with figure 1 to attach Figure 8 The installation device for frequency converter of the present invention is introduced in detail.

[0044] The device described in this embodiment that requires heat dissipation is a frequency converter. Although in this embodiment only the frequency converter is used as an example to illustrate the installation device of the present invention for equipment with heat dissipation requirements, the installation device can be used not only for frequency converters, but also for all heat dissipation parts. , a device that requires cooling of the device itself and the outside. The devices with heat dissipation requirements mentioned here usually need to be installed in a cabinet, and at the same time, the heat dissipation part needs to exchange heat with the air outside the cabinet.

[0045] figure 1 Shows a front view of a cabinet using the installation device for frequency converters of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com