Mechanism heat-dissipating device of sewing machine adopting direct drive motor

A heat dissipation device and sewing machine technology, applied in sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve the problems of lack of alignment structure, lack of heat dissipation of internal components, and inability to dissipate heat smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

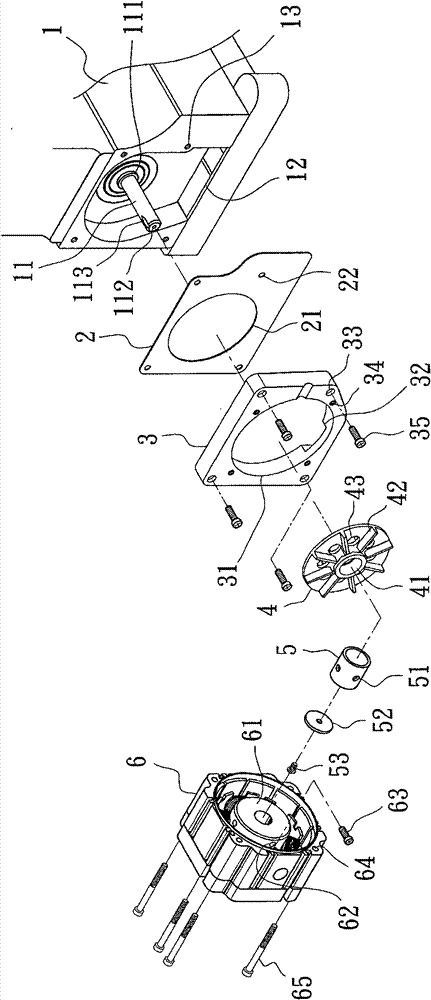

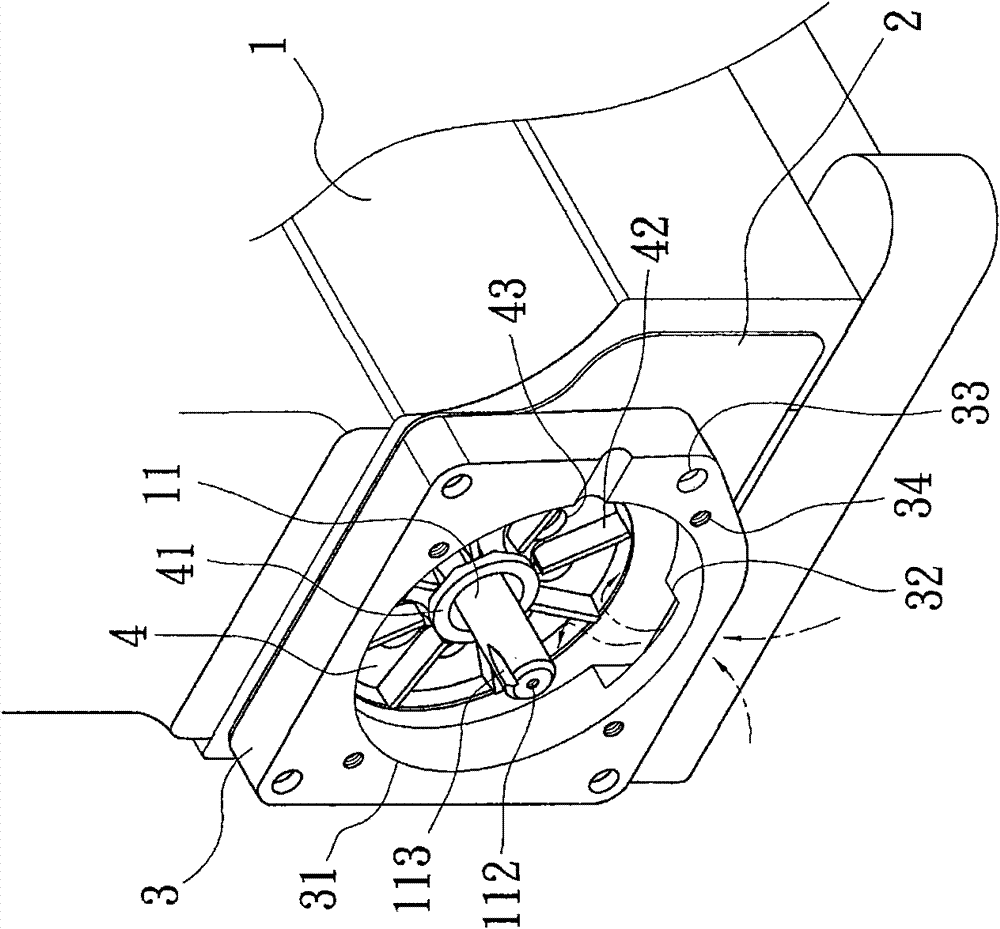

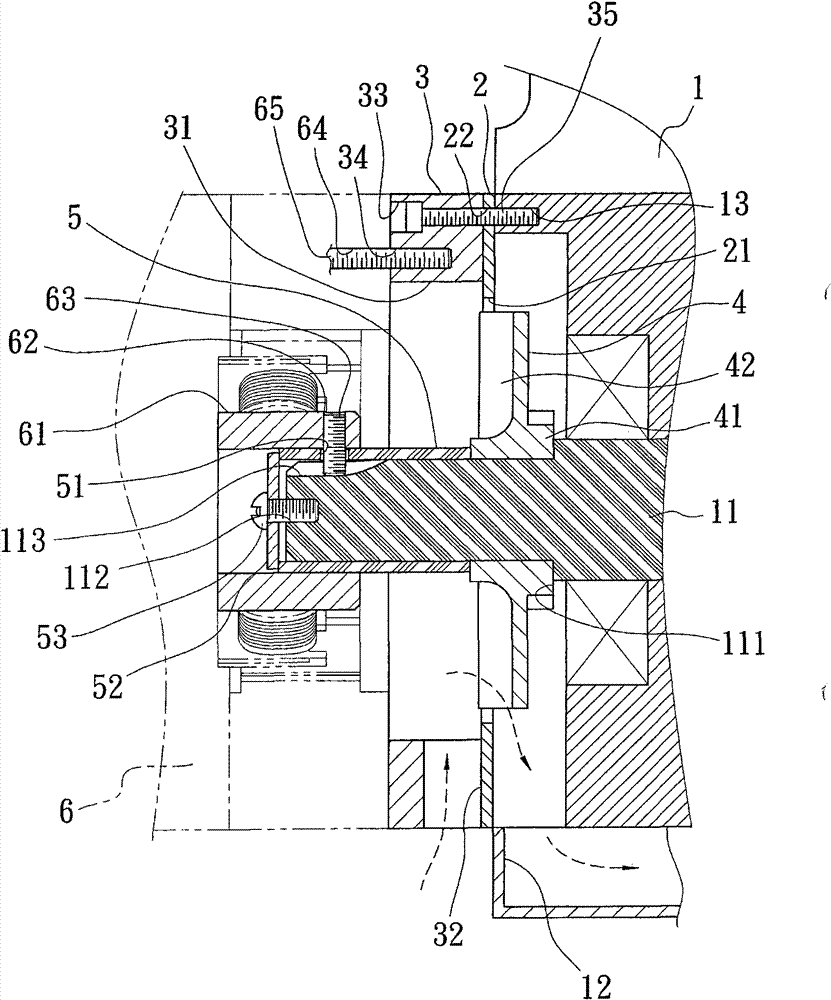

[0033] First, please refer to figure 1 , figure 1 It is a schematic diagram of Embodiment 1 of the heat dissipation device for the sewing machine mechanism of the direct drive motor of the present invention, which includes a sewing machine body 1, a partition plate 2, an adapter 3, a fan blade 4, a clamping member 5 and a direct drive motor 6. Wherein: the side of the sewing machine body 1 is protrudingly provided with a main shaft 11, the inner end of the main shaft 11 is formed with a card edge 111 for resisting the fan blade 4, and the outer end surface of the main shaft 11 is axially provided with a The screw hole 112 is used for locking the screw member 53 of the clamping member 5, and at least one groove 113 is axially opened on the peripheral edge of the outer end of the main shaft 11 for clamping the screw member 63 of the direct driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com