Carbon nanohorn adsorbent and process for producing the same

A technology of adsorption materials and manufacturing methods, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as high density, deterioration, lack of chemical stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A φ30×50mm graphite object rotating in a room temperature, 760Torr, Ar gas drying reaction chamber is irradiated with CO with a wavelength of 10.6μm by a beam with a diameter of 10mm. 2 Laser, and the resulting carbon nanotubes are recovered from the collection filter. The obtained carbonaceous nanotubes were assembled in a structure in which a plurality of carbonaceous nanotube tubular parts were located at the center and conical parts projected like horns on the surface, and it was a spherical single-layer carbon nanotube aggregate with a diameter of about 70 nm. The diameter of the tubular portion of each carbon nanotube is about 2 to 3 nm, and the length of the tubular portion is about 30 nm.

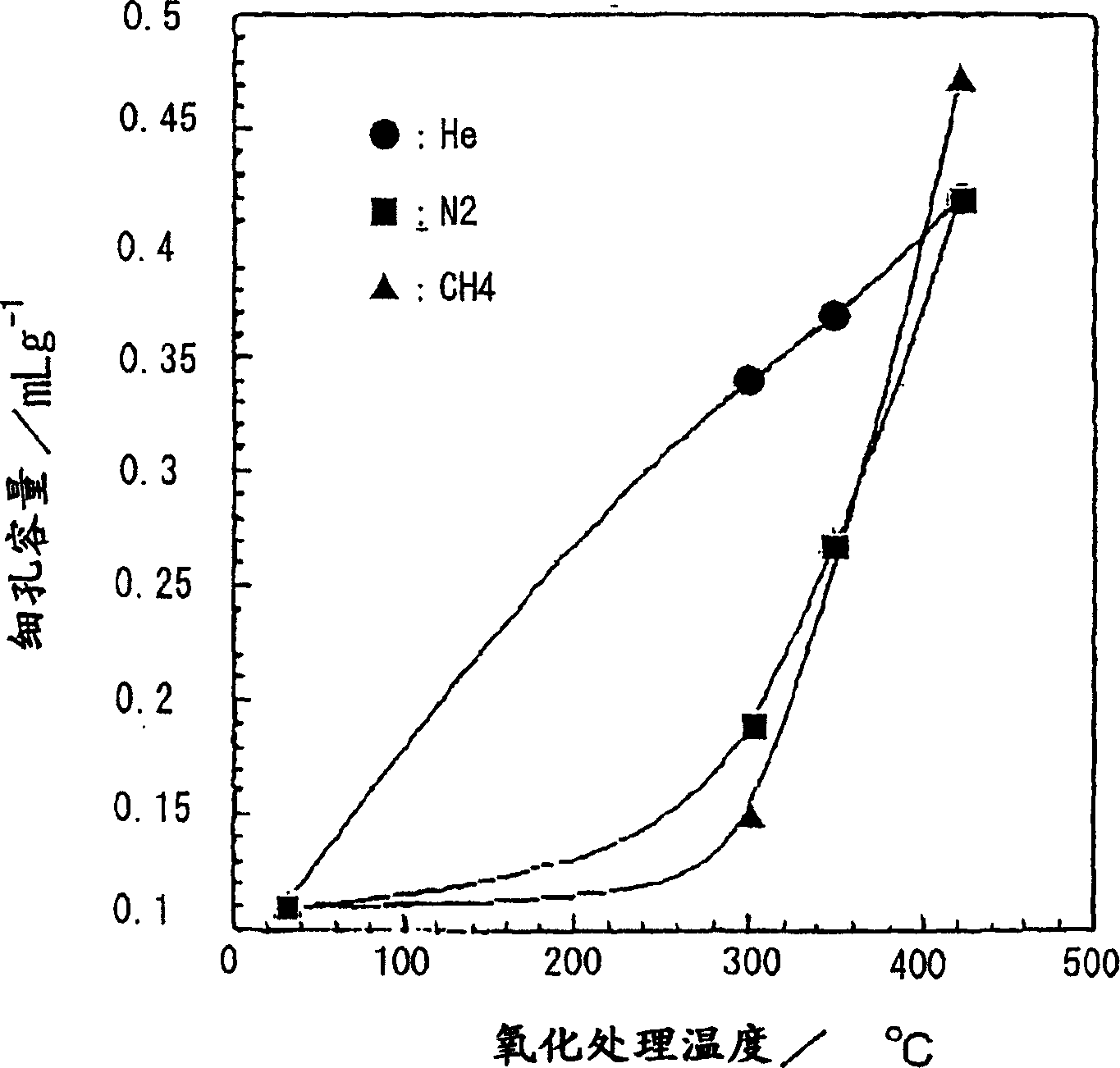

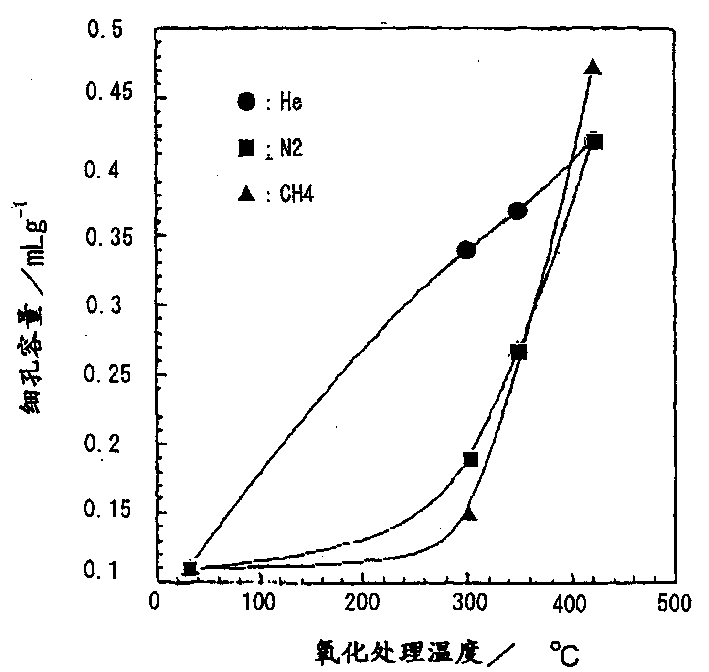

[0027] The carbon nanotubes were oxidized for 10 minutes under three conditions of an oxygen pressure of 760 torr and a treatment temperature of 300° C., 350° C., and 420° C. respectively. Take the untreated carbon nanotubes as NH0, and treat the treated carbon nanotubes as ...

Embodiment 2

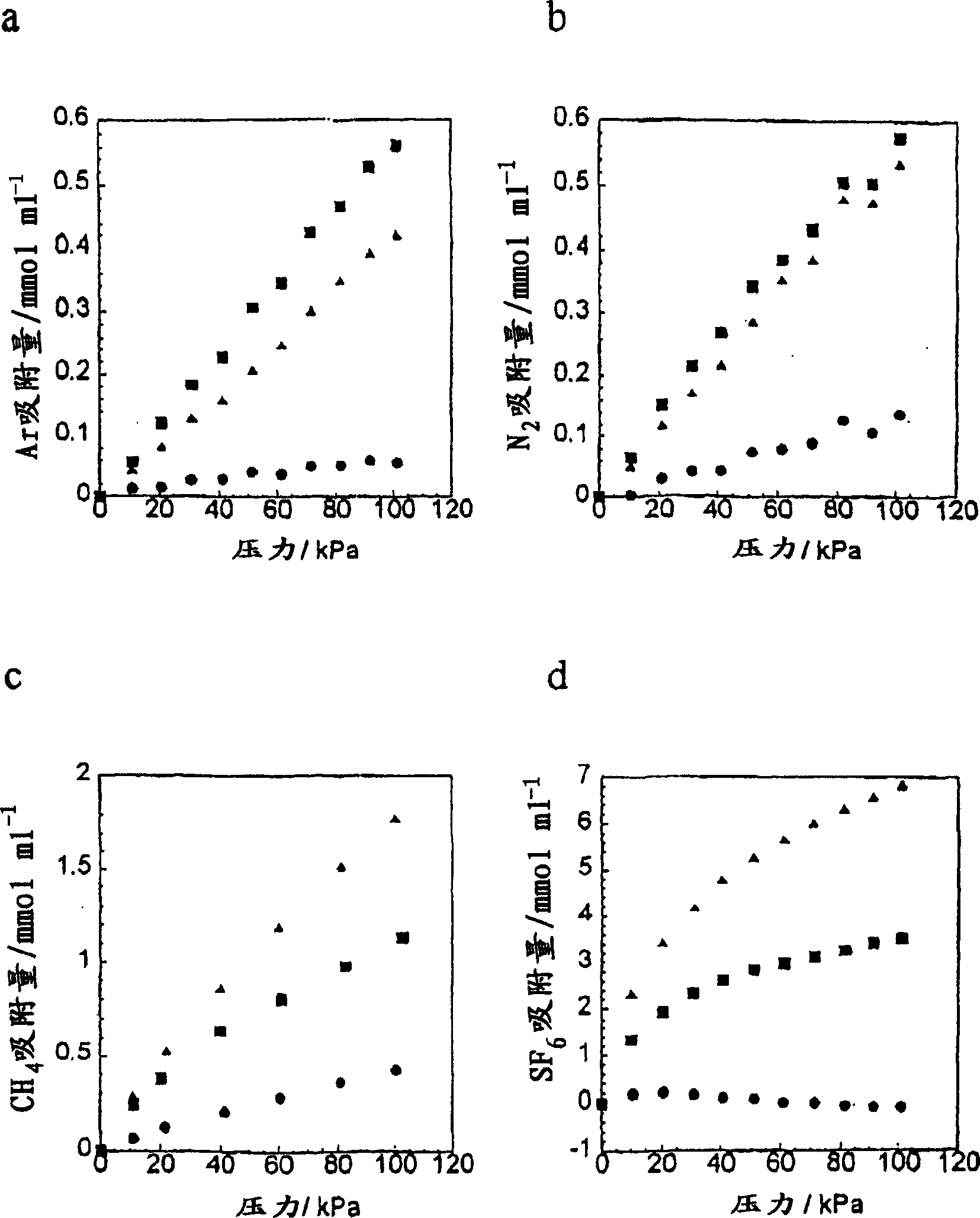

[0037] The molecular sieve effects of NHO, NH300, NH350, and NH420 similar to those in Example 1 were investigated using molecules of various diameters.

[0038] As a molecule of a non-adsorbing substance, the molecular shape is basically spherical, and there are only dispersion forces between the molecules, that is, from the perspective of molecules without preferential intermolecular interactions, He, Ar, and N 2 、CH 4 , SF 6 and C 60 , and the diameters of these molecules are shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com