Process for production of multifunctional composite bicomponent fiber spunbond nonwoven fabrics

A technology of spun-bonded nonwovens and composite fibers, which is applied in the field of composite long-fiber nonwovens manufacturing. It can solve the problems of no general-purpose production line and inability to use both, and achieve the effect of low product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

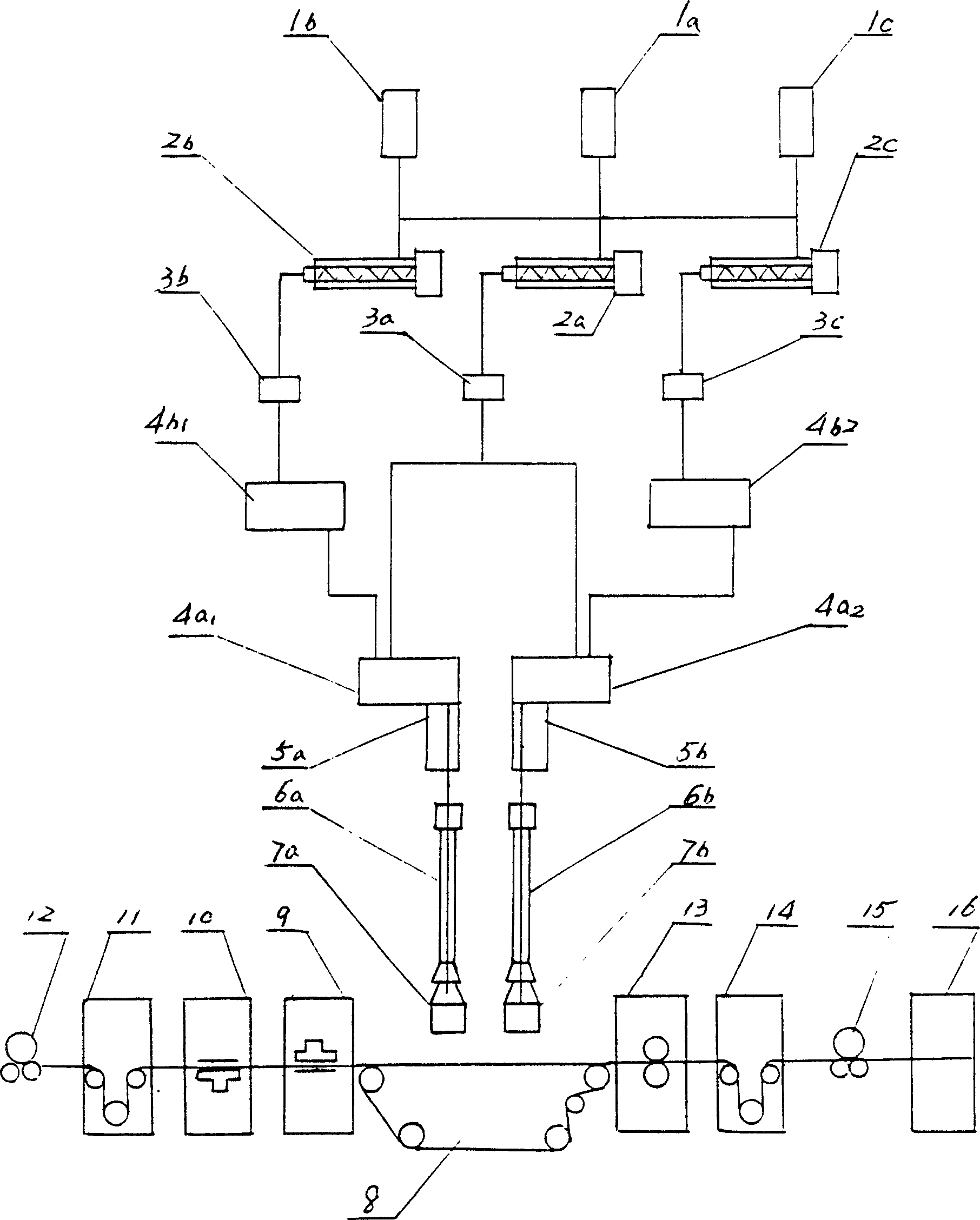

[0026] Production of PET / COPET bicomponent fiber spunbond woven fabric. The technological process is shown in the accompanying drawing.

[0027] (1) Production of two-component spunbonded needle-punched nonwovens. In the process flow, the web forming machine travels in the direction of feeding the fiber web to the needle loom. PET is dried in 1a, separated after extrusion in 2a, filtered in 3a and enters two main spinning machines 4a 1 , 4a 2 Middle; COPET is dried in 1b and 1c respectively, squeezed in 2b and 2c, filtered in 3b and 3c respectively, and enters into respective sub-spinning boxes 4b 1 、4b 2 , and then enter the two main spinning boxes for two-component composite spinning. The same tows ejected from the two main spinning boxes are cooled by side blowing at 5a and 5b, drafted at 6a and 6b, and laid at 7a and 7b to form a fiber web evenly on the net curtain of the web forming machine, and sent to the needle The needling machine is conveyed, through the acupun...

example 2

[0035] Production of PET / PA6 bicomponent fiber nonwovens.

[0036] (1) Production of bi-component fiber spunbonded needle-punched nonwovens. The handicraft process is as in Example 1 (1), except that COPET, one of the raw materials, is replaced by PA6. The production process and process condition control are different as follows:

[0037] PA6 is dried in 1b and 1c respectively, the temperature is 150±1°C, the working temperature of the screw extruder is 278±1°C; PA6 enters the auxiliary spinning box and its working temperature is 275±1°C; the number of holes in the spinneret of the main spinning box It is 36f×12, 36f×16, 72f×16, and it is orange segment type; the cloth speed of the web forming machine is 4.6m / min when conveying the fiber web to the needle loom. All the other process condition control is the same as (1) of example 1. The product PET / PA6 spunbonded needle-punched nonwoven fabric has a width of 5.3m and a weight of 280g / m 2 , monofilament fineness 4.0dtex.

...

example 3

[0040] Production of PET / PBT bicomponent fiber spunbonded hot-rolled nonwovens.

[0041] The technological process is as example 1, and the web forming machine conveys the fiber web to the hot rolling mill. COPET, one of the raw materials, was replaced by PBT. The control of process condition is all identical with example 1 except following changes:

[0042] PBT was dried in 1b and 1c respectively, the temperature was 150±1°C, the drying time was 5h, and the water content of all dried resins was ≤30ppm. The dried PBT is extruded by screw respectively, and after being filtered, it first enters the sub-spinning machine and then enters the main spinning machine to be combined with PET for spinning. The working temperature of PBT in the screw extruder is 278±1℃, and the temperature of the workpiece entering the auxiliary spinning machine is 279±1℃. The number of holes in the spray plates of the two main spinning boxes is 96-120f, which is orange-petal type. After the spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com