Color sorting machine

A color and machine technology, applied in the field of color sorting machines, can solve problems such as inability to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

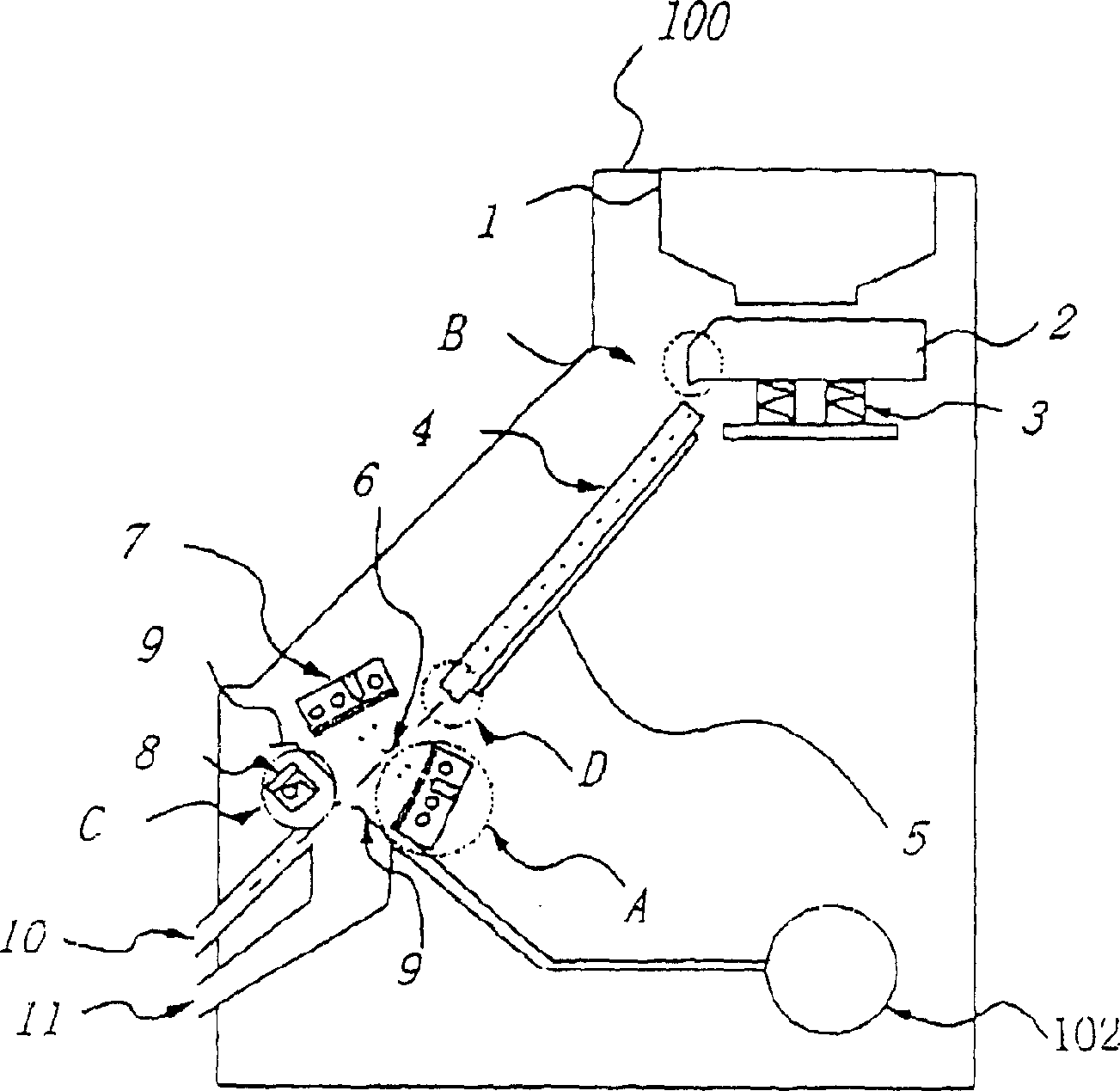

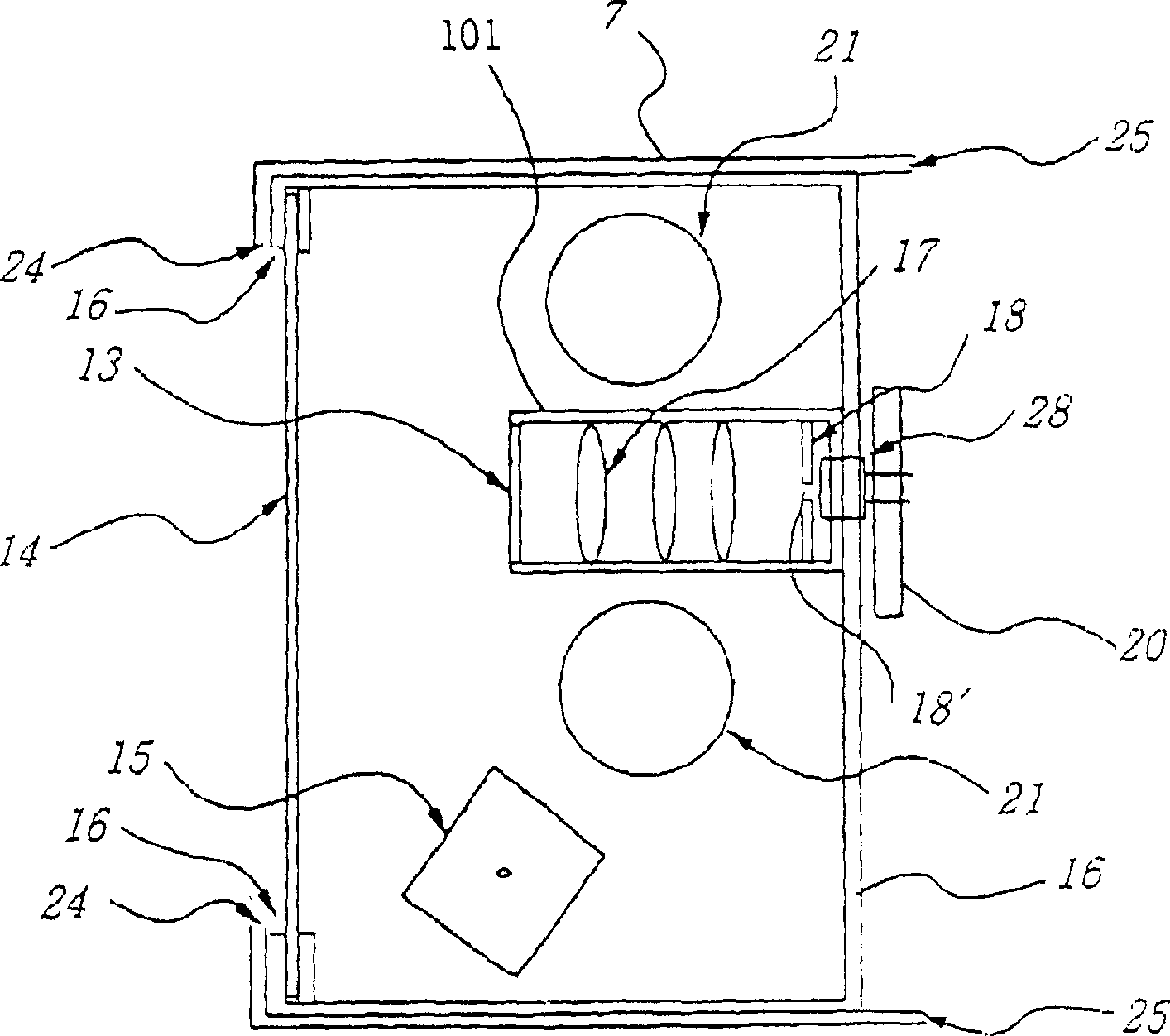

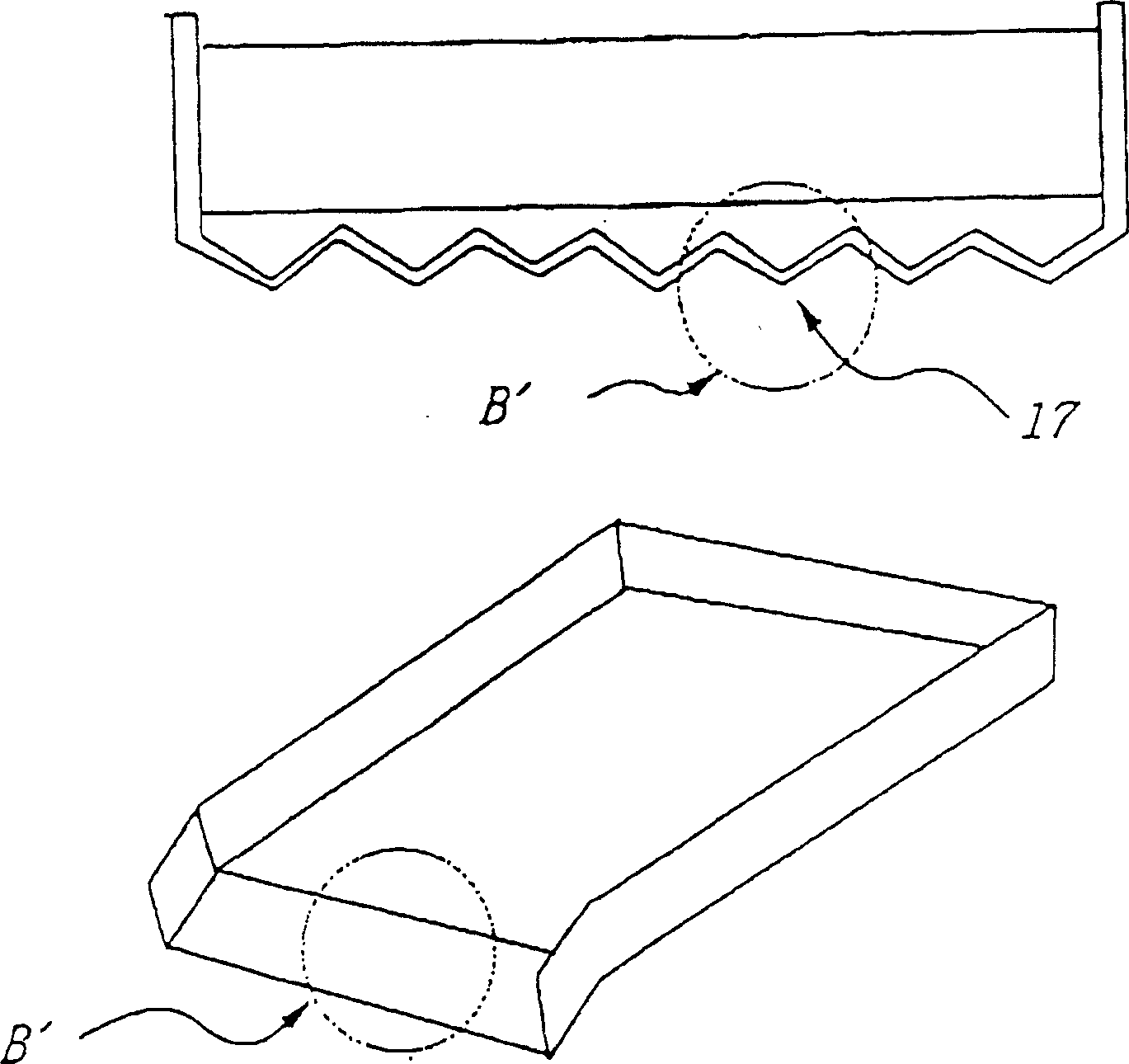

[0014] figure 1 It is a sectional view of the color sorting machine of the present invention. refer to figure 1 , the color sorting machine 100 includes a hopper 1 located on the upper part for containing granular materials and a feeder 2 located below the hopper. Such as image 3 As shown, the feeder 2 has such a structure that its front end is inclined, thereby allowing the granular material to run down to a descending slope 4 easily and evenly, and a V-shaped or U-shaped guide groove 17 is also formed. (see image 3 the upper part of the). The guide grooves 17 coincide with the individual channels of the down ramp 4 , allowing the granular material to enter the down ramp 4 evenly and precisely. A vibrating part 3 is located below the feeder 2 . Below the feeder 2, several channels are formed, each channel comprising a descending ramp 4 with a U-shaped or V-shaped bottom. Under certain air conditions, such as a high percentage of humidity, the descending ramp 4 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com